|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wilbur’s works

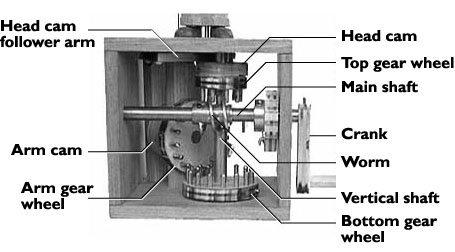

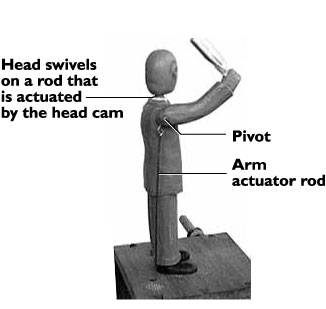

Wilbur stands on a box that is 3-1/4" high and wide x 2-3/4" deep. The figure stands 4-3/4" tall. The automaton is made entirely of wood and metal, except for his head, which is made of polymer clay. Wilber is painted, his workings are not.

The pictures below are brought to you in sparkling black and white (to reduce download time). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

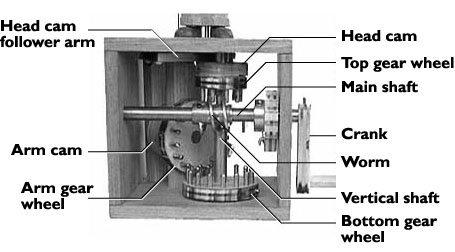

Above left is the front of the mechanism. When the crank (which is attached to the main shaft) is turned, the worm rotates. This engages the top gear wheel. Each revolution of the crank advances the wheel, which has nine teeth, one tooth. So it takes nine revolutions of the crank to rotate the top gear one full turn, or one complete cycle of the motion. The top gear wheel turns the vertical shaft, to which the bottom gear wheel is also attached. Above the top gear wheel is the head cam, which controls the movement of the head.

The bottom gear wheel engages the arm gear wheel. Mounted on the same shaft as this wheel, and behind it, is the arm cam, which controls the movement of the arm. The bottom gear wheel and the arm gear wheel have to be carefully meshed so that the timing between the head and the arm is correct. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

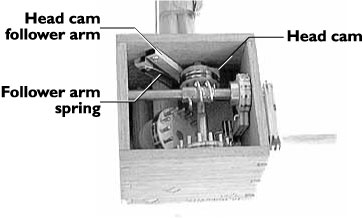

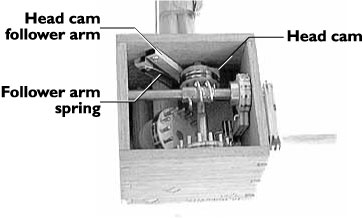

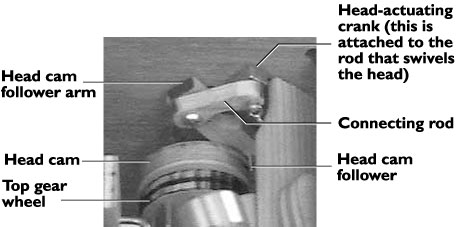

Looking up at the "ceiling" of the mechanism, the head cam and follower arm can be more clearly seen. As the head cam rotates, the follower arm, kept against the cam by the spring, tracks the cam's motion and transmits it via a connecting rod to the crank to which the head's rod is attached. This can be seen in the rather blurry picture below, which was taken from the back of the mechanism. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

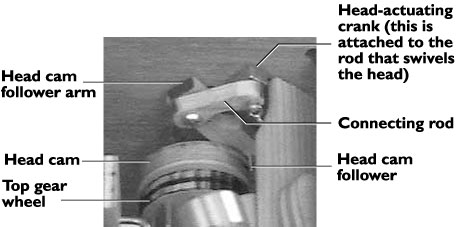

Here, the head-actuating mechanism can be seen. As the head cam rotates, the follower attached to the follower arm stays in contact with the rotating cam, moving as the cam changes shape. The connecting rod attached to the follower arm causes the crank, to which the head rod is attached, to rotate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

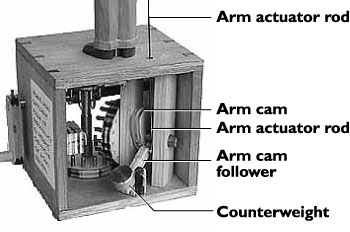

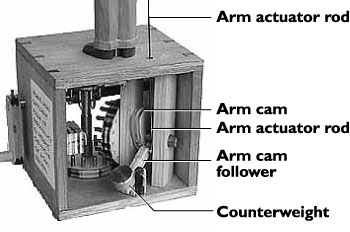

Looking at the back of the automaton, the mechanism that operates the arm is visible. The arm cam, rotated by the arm gear, causes the arm-cam follower to move up and down. The arm actuator rod is attached to the follower, which causes the arm to move up and down, too. The little counterweight just makes sure that the follower drops when it is supposed to. |

|

|

|

|

|

|

|

|

|

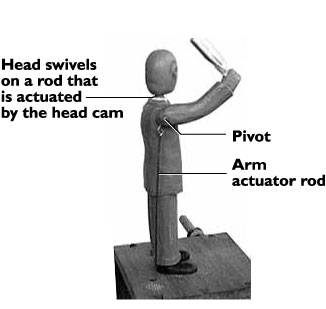

The arm has a simple hook in the shoulder to which the actuator rod is attached. The rod pulls the arm up and its own weight brings it down again.

The head pivots on a rod that passes all the way through the body and is attached to the crank just under the floor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To return to the Gallery page, click here.

|

|

|

|

|

|

|

|

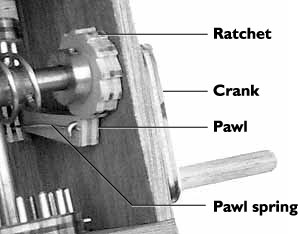

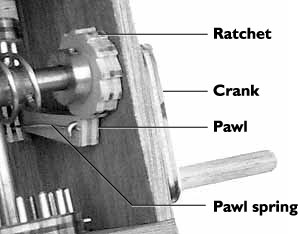

Because the motion would only look right when the crank was turned in the proper direction, a device was necessary to prevent it being turned in the wrong direction. Hence, the ratchet and pawl. The pawl spring keeps the pawl engaged with the ratchet and it makes a nice noise when the crank is turned. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This page and its contents copyright 2001 by Sidestreet Bannerworks

|

|