Berkeley Locomotive Works: A history

by Michael O'Rourke

Photos by the author

Since my teenage years, I had wanted to produce and market a miniature live-steam locomotive, but it wasn't until the introduction of LGB in the late 1960s that the idea jelled. LGB's size was natural for an affordable, miniature live steamer.

I established Berkeley Locomotive Works in the early 1990s, starting by producing after-market alcohol burners for the Mamod locomotives. After a couple of not entirely successful attempts to produce an American outline locomotive using Mamod technology -- including the Lonesome Dove -- I discovered an advertising illustration for a small, geared, contractor's locomotive manufactured by the John F. Byers Machine Co. of Ravenna, Ohio, in John H. White Jr.'s A Short History of American Locomotive Builders. The little locomotive spoke to me and seemed a perfect fit for what I had in mind. Thus the Cricket Steam Motor was born.

Lonesome Dove, based on the Mamod engine.

The Prototype

Cricket was designed to be an inexpensive, entry level, American outline, live-steam locomotive for the garden-railroad market. At the time of its production, it was the only garden-scale live steamer produced in the United States. The advertising line cut upon which Cricket was based offered little in the way of detail and, as there were no other drawings or illustrations available at the time, the design was extrapolated from the line cut. Thus, Cricket was largely an interpretation of the engine rather than a model. It was posited that the engine was driven by a single vertical steam engine -- a stock item in the Byers catalogue -- with a flywheel on the fireman's side. If true, this arrangement would have allowed the engine to be driven to a job site, the wheels disconnected from the drive train, and the unit used as a power source for a hoist, sawmill, or other device through a belt drive from the flywheel.

This, in fact, was not the case. Recently revealed drawings from Engineering News of 1896 show the engine as having two vertical engines -- one port and one starboard -- and no flywheel, thus precluding it's use as a movable power source.

With the all the small, industrial locomotives available at the time, it is difficult to determine just what market niche the Byers engine would have filled. Certainly, its gearing would have allowed it to tackle grades that conventional rod engines could not, and its extremely short wheelbase would allow it to traverse the tight curves found at quarries, lumber and mill yards, and other job sites, where hastily laid or portable track systems were the norm. However, it apparently was not a best seller for Byers, as it never appeared in any known Byers catalogues, and probably no more than a half dozen engines were ever built. For a more comprehensive description of the prototype engine and it’s history, click here.

The Model

Actual production of the Cricket began in 1994. In all, about 130 units were produced and sold worldwide. The engine featured in this "Locomotive of the Month" was built for Rich Chiodo of New Hampshire. It is one of the last engines off the BLW line and the only double. It features a T-boiler made from common plumbing parts, with a 5/8"-diameter flue fired by a slotted poker burner.

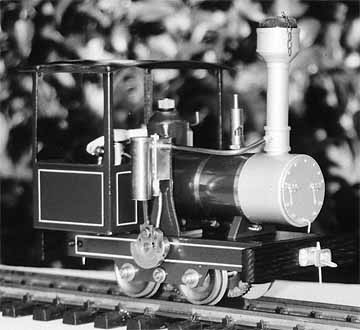

The original Cricket. Early models had oscillating cylinders.

.

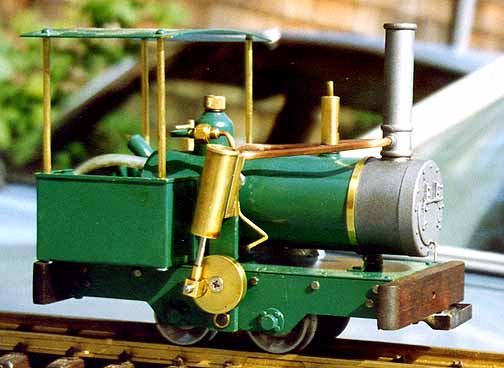

A Cricket made for Jerry Reshew, called the "Irish" Cricket for its green and white livery.

The water and pressure gauges are by Fyne-Forte Fittings, the 1/2"-diameter pressure gauge by the Miniature Pressure Gauge Company, and the whistle by Mamod. Operating pressure is about 30 psi. The boiler is lagged with an insulation material known as Fiberfrax, and is wrapped with a stainless-steel jacket held on by brass bands. The bell is from Trackside Details. The dome is a BLW product, and conceals the Goodall valve. Gas is carried in the rectangular tank in the cab on the fireman's side, and refueling is done through a ‘“fueling spike” dropped through a hole in the cab roof.

.

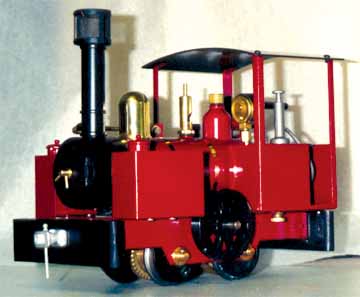

A "Plantation" type with side tanks, built for Kevin Schindler.

.

Two in LGB livery for a man in Germany. These were the first to use a proper smokebox and were somewhat difficult to fire.

The motors are single acting and reversible through slip eccentrics. As the piston rods are connected directly to the pistons through a ball joint, the motors have more in common with automotive practice than conventional marine or locomotive construction. Wheels are driven through five brass and steel spur gears at a ratio of 1:5.79. The lubricator has no drain; accumulated water must be sucked out by a syringe.

The single-acting cylinders and the slip eccentrics resulted in control problems. Getting it started required that the cranks be properly set to a specific “starting” position. Cranks often caught “opposite," resulting in no motion and much hissing from the safety valve. It is almost impossible to reverse the engine unless it has been allowed to sit for a few minutes, so that any pressure in the cylinders can dissipate. Opening the throttle too quickly often caused the engine to do a "wheelie," as the two motors produce an incredible amount of torque for such a small engine, and the ‘T’ of the boiler puts a lot of weight at the rear. Mounting a slug of type metal under the frame in front solved this problem. These annoyances could perhaps have been mitigated by offsetting the cranks, a theory Kevin O'Connor explained to me, but which I could never quite grasp. The double crank assembly on the flywheel side is somewhat inelegant. Were I to build another double, I would mount the flywheel inside the frame or eliminate it altogether.

Fortunately the engine was ordered unpainted. I found that getting a really good paint job could take up 35% of production time. There was enough to do on this engine, so no paint was a boon. It also allows the viewer to appreciate the inherent beauty of the raw metal.

.

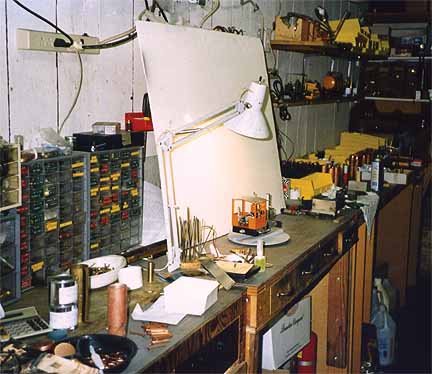

A shot of the old workshop on Hillegass. A finished Cricket is having its picture taken.

Production of Cricket ceased in 1999. It was apparent that Bing Cheng of Accucraft was coming on strong with an entry level, American outline, live steamer at a considerably lower price point than Cricket.

.

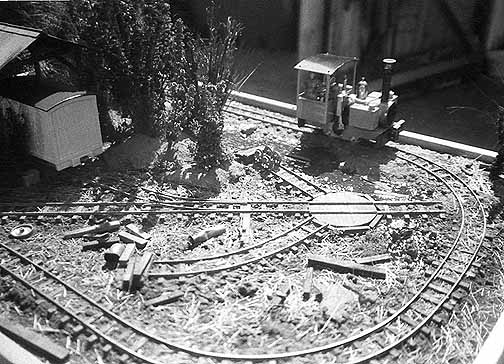

This 30" x 42" portable Plantation Pike had 1"-gauge track to represent a 20"-gauge Hawaiian sugar-field line. Yes, the engine did really get around those 9"-radius curves. The pike was often seen at shows.

.

The Berkeley Locomotive Works booth at the Big Train Show on the Queen Mary in 1996 or 1997. A total of eight Crickets, all different, can be seen here.

The remainder of the parts has been sold to a gentleman on the east coast, and we await the first production run of a revitalized Cricket. Although the niche for which Cricket was intended has been admirably filled by Accucraft, Cricket's unique outline and unsurpassed hill-climbing abilities make it an interesting and valuable addition to any roster.