A review

by Marc Horovitz

(2-19-03)

| Specifications | |

| Builder | Accucraft Trains (China) |

| Gauge | 45mm (gauge 1) |

| Scale | 1:20.3 (15mm = 1'-0") |

| Boiler | Copper, silver soldered, twin flue, gas fired |

| Fittings | Safety valve, filler plug, throttle, pressure gauge, water glass, blowdown valve |

| Fuel | Butane |

| Blow-off pressure | 70 psi |

| Cylinders | Two fixed, double acting, D-valve |

| Reversing gear | Walschaerts, controlled by lever in cab |

| Lubricator | Displacement, with drain |

| Other features | Fully sprung chassis; working drain cocks, |

| Dimensions | 36" long (engine and tender); 5-3/4" wide; 7-7/8" tall |

Accucraft Trains

31112 San Clement Street

Hayward CA 94544

Price: $3,999.99

Web site: www.accucraft.com

Pros: Highly detailed scale model; excellent fidelity to prototype; easy to operate; will run up to an hour unattended; can be radio controlled; will pull prototypical-length train; large boiler; large fuel tank; will self start, even when cold; correct scale-to-gauge ratio

Cons: Lubricator cap a little awkward; drawbar is too long for prototypical coupling; blowdown taken from top of water glass instead of bottom; access to valves (for setting or adjustment) difficult; toy-like safety valve; no pumps provided; front coupler a little high

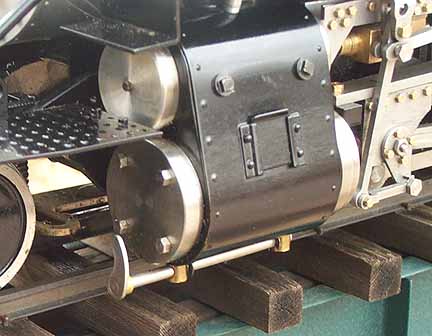

Our review sample is a model of Nº 461. As narrow-gauge locomotives go, the prototypes are exceedingly large engines. The model, consequently, is also quite large, so make sure you have enough clearance and large enough radii (8'-10' should do) on your railroad to handle them. Accucraft’s offering is well made entirely of metal. All side rods and valve-gear parts are nicely proportioned. The boiler is made of silver-soldered copper and operates at around 70 pounds per square inch pressure. The locomotive burns butane gas, which is housed in a tank in the tender under a dummy, lift-out coal load. There are two flues in the large boiler, each of which contains a standard “poker”-type burner. Twin, removable gas jets are attached to the end of a single, flexible line from the gas tank.

Locomotive and tender are coupled via a drawbar. This has two holes in it for variable spacing of the engine and tender, depending on your minimum radius. However, even the closest spacing is too far apart and the apron between loco and tender cannot engage the tender deck, so just hangs behind the loco. I’d like to see a drawbar with more holes, including one that will allow prototypical coupling between loco and tender.

I did all of this prep work on the bench, then placed the engine on the rails. To light the fire, I opened the smokebox door (which just snaps shut), struck a match, and opened the gas valve in the tender a little. The fire lit right away in both flues, flashing back to burn above the pokers with a slight “pop”. I found, through experience, that it is possible for one burner to go out while the other stays lit. The one that goes out will not self light from the other one. There is no real way of knowing, except by the sound of the burner (which takes practice to detect), if one has gone out. However, this didn’t happen often, so should not be a major concern.

Once pressure had come up to the blowoff point (around 70 psi), I removed the cab roof, put the engine in forward gear, and opened the drain cocks and the throttle. Steam hissed from the cylinder drains and condensate was expelled. The engine slowly moved forward as the cylinders warmed, then strongly took off. I found that the drain cocks would not completely close, so steam could be seen coming from the cylinders at all times during operation. This did not seem to affect the way the engine ran, though, and it looked great.

After the engine ran a couple laps around my track, I tied on a train of four, heavy Accucraft freight cars and a very heavy all-metal caboose. The engine walked away with these and would no doubt have handled several more. Top speed was a sedate (estimated) 25-30 scale mph. The throttle knob can be more-or-less conveniently reached with the cab roof on, but the reversing lever is more difficult. Our review sample ran slightly better in reverse than forward, probably a matter of the valve setting. The valves on this engine are more difficult to get at than on other locomotives. This is a model of a piston-valve locomotive, but it uses D-valves. These are concealed beneath the cylinder covers, which must be removed. The footplates above the cylinders must also be dismantled before you can get to the valves for adjustment. Full Walschaerts gear controls the valves.

At the end of the run I blew down the boiler, using the valve under the right side of the cab. The takeoff for the blowdown is at the top of the water glass, not the bottom, which is usual. Because of this, blowing the boiler down will relieve the steam pressure, but will not drain the boiler.

No provision is made for radio controlling the engine, but it shouldn't be too big a job. You'll need two servos—one for the throttle and one for the reversing lever. There is room in the cab for these. The rest of the gear could be mounted in the rear part of the tender.

If you are looking for a sophisticated steam locomotive that requires a lot of hands-on attention to achieve the best performance, perhaps this locomotive is not for you. However, if what you want is a good, solid, accurate, well-built model of an interesting prototype, one that can be fired up and more or less ignored for the next hour or so, this is definitely one to consider.

This page and its contents Copyright

Sidestreet Bannerworks, 2003