Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

August 2004

Hugh Saunders' Manning Wardle 0-4-0T

by Marc Horovitz

The prototype of this model was built by Manning Wardle of Leeds, England, in 1897. This was the year of Queen Victoria's Diamond Jubilee (60 years on the throne) and the engine was named to commemorate that event. It was originally supplied to the Cilgwyn Quarry in North Wales, where it worked until 1928. It was then purchased by the Penrhyn Quarry, where it worked until it was retired in 1955. It exists today, although not in working order, at the Narrow Gauge Railway Museum in Tywyn, Wales, next to the Talyllyn Railway.

The model

The late Hugh Saunders was a private commercial builder in the UK. His work was always to a very high standard and he built engines in a variety of different scales and gauges. (To see another Hugh Saunders engine, click here.) This model is in 16mm scale for 32mm gauge. Its internally fired boiler is alcohol fired and features a firebox, with a single flue communicating with the smokebox. Both firebox and flue contain water-circulation tubes. There is a fire door in the usual position that can be used to ignite and check on the fire.

The backhead has most of the requisite amenities, including a throttle, blower valve, pressure gauge, and water glass. Atop the boiler is a working saddle tank. A balance pipe beneath it keeps water in the legs of the tank at the same level. Water can be added at any time through the filler cap. It is then pumped into the boiler via the hand pump mounted on the footplate on the right side of the cab.

Reversing is via slip eccentrics, which drive the inside valves. Cylinders are outside the frames. The rods are properly profiled and even have working oil cups to lubricate the bearings. A large displacement lubricator is located below the deck in front of the smokebox. It has a drain plug underneath, but access is awkward.

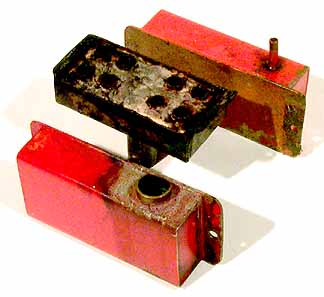

The burner is of an unusual design. It is basically a box stuffed with wick material, with eight air tubes coming up through it to keep the fire from starving. The burner is fed by a pair of tanks that reside under the footplate. A little trap door on the floor of the left side of the cab can be opened to replenish the fuel. The supply tube to the burner also functions as a balance pipe between the two tanks, so only one need be filled.

The run

When I acquired this engine (third or fourth hand), it had obviously seen better days. I won't say that it had been abused, but it had certainly been used hard. I know that some work had been done to it before I got it, to get it in good running order. When it first arrived, I gave it a run on a friend's railway. It ran very well until a crankpin on the rear axle mysterious disappeared. That was that.

For today's run, a repair had to be made. I removed the screw on the remaining opposite crankpin to see how it all went together. I was sort of expecting a long, shouldered screw to hold the rod ends in place. But no -- this engine has proper, shouldered crankpins, pressed into the cranks. A screw, with a special washer, screws into the end of the crankpin to keep everything in place.

I carefully measured the remaining crankpin and the hole the lost one had worked loose from, and turned up another out of drill rod. The end of the original was threaded 8BA, and a hex screw retained the rods. I didn't have a hex screw, but I did have an 8BA flathead screw. I drilled and threaded the end of the new pin, turned up a new retaining washer, and countersunk it for the flathead screw. I then pressed then new pin into its crank, with a tiny dab of Loctite for good measure.

Once the Loctite had a chance to set, I reassembled the rods. The main rod from the piston was distinctly ovaled from wear and possible lack of lubrication.

Run day was a toasty 90 degrees in Denver. I filled the saddle tank with water and pumped up the boiler until three-quarters of a glass showed. Then I suctioned out the lubricator and refilled it with steam oil. Finally, I filled the fuel tanks through the little trap door in the cab.

Since this is an internally fired loco, a suction fan was necessary to raise steam. I used my trusty old Aster fan, which fit the stack well. I lit the fire through the fire door. This is one of few engines that has an audible alcohol fire. If there is too much draft, it really hums. Steam came up to 20 pounds in about five minutes. I took off the fan and turned on the blower.

Another couple minutes brought the pressure up to 40 psi. I opened the throttle and pushed the engine until the cylinders were clear and it began to show signs of life, at which point it moved off easily by itself. I closed the blower and let it go -- a mistake. After half a lap, pressure was down and the fire had died. On some engines, you have to keep the blower cracked if you want to keep pressure up when running light. Otherwise, the exhaust draft is insufficient to maintain the fire.

I relit the fire and reapplied the fan. Pressure came up quickly. This time I left the blower cracked, and all was well. The engine trundled around lap after lap, with pressure never dropping below 40 psi. It ran smoothly, but with an audible click (those oval bearing holes in the main rods). Altogether, it was a satisfying run of a much-used engine made by a master builder.

.

|

|

|

| Builder | Hugh Saunders (UK) |

| Date built | 1980s (?) |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Single flue with firebox and cross tubes |

| Fittings | Safety valve, water glass, pressure gauge, throttle, blower, pump |

| Fuel | Alcohol |

| Blow-off pressure | 60 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Dimensions | Length, 11-1/8" over the end beams; width, 3-13/16"; height, 6" |

This attractive and well-made model nicely captures the lines of the prototype. Although it has seen hard use over its life, it is still in good running condition.

.

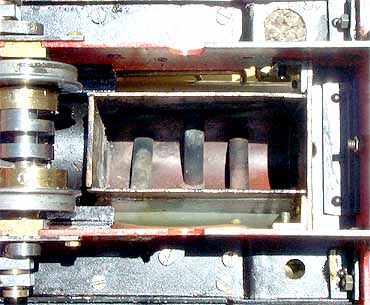

A peek into the firebox reveals three water-circulation tubes. There are more cross tubes in the flue.

.

This unusual burner heats the water. There is evidence of a past cab fire near the large filler hole.

.

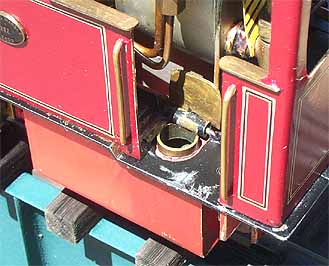

Above: Fuel can be added through the trap door in the cab floor. The engine can be kept in steam indefinitely.

Right: A workmanlike cab interior. The hole in the backplate is for access to the fire door with a flaming match.

The saddle tank is filled through this hatch. It is then pumped into the boiler with the hand pump on the cab floor (right).

.

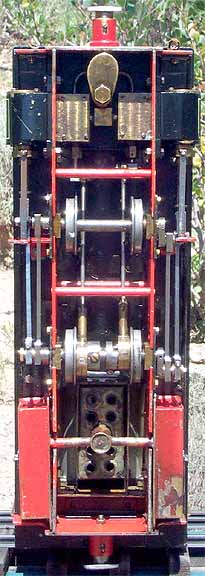

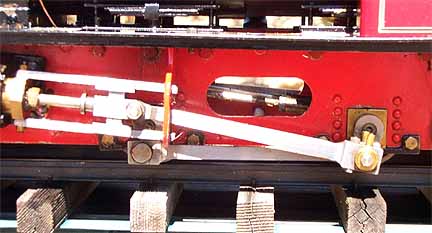

Left: Slip eccentrics on the rear axles drive the inside valves. Note the odd, oval shape of the lubricator between the valves. The burner fits the firebox very closely.

Above: Side and main rods are milled to the proper shape from bar -- no stamped, sheet-metal rods here! The oil cups above the crankpins are functional and do an effective job of lubricating the bearings.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004