Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

December 2004

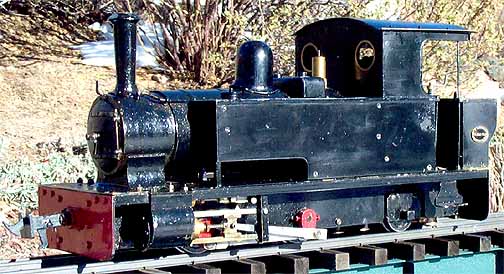

Denis Jukes' Gelert

by Marc Horovitz

This is a model of Gelert, a relatively modern locomotive, built in 1953 by the British firm of W.G. Bagnall for the Rustenberg Platinum Mines in South Africa. It was one of four, similar, 2’-gauge locomotives supplied to the mines. The locomotives were used to haul platinum ore from the mines to the reduction plant.

In 1980, when the 2’-gauge line had been replaced by a larger gauge, the locomotive (along with a sister engine) was purchased by the Welsh Highland Railway (WHR) in Wales. It sat for many years awaiting restoration, which was finally completed in 1992. It was then that it received the name Gelert. The engine runs today on the WHR. A photo of the prototype can be seen here.

The model

The builder of this model is Denis Jukes, a retired metalurgist who moved to Hereford upon retiring. Denis passed away around 2002, in his 80s. (Thanks to Dave Lemar for the information about Denis.) The engine is well constructed and captures the proportions of the prototype nicely. It incorporates a number of unusual features. The engine is alcohol fired using a chicken-feed system. The tank, which resides in the bunker, slides right out. With the valve closed, it can be filled outside the engine, then just dropped into place. Feed and vent tubes protrude from the bottom of the tank into a sump, when in position. The burner has two good-size wicks.

The boiler is internally fired, and appears to be of the Wrighton variety. It has a proper firebox connected to a single, large flue with cross tubes. The smokebox door has a working dart (the twin handles on the front), which is a nice feature. One handle loosens the latch, while the other disengages it, allowing the door to be opened.

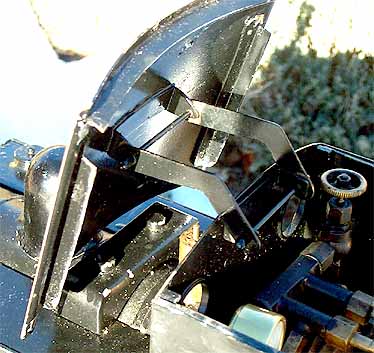

All the valve-gear parts are hand crafted to a high standard, as is the entire locomotive. The detail level is not high, as the engine was evidently designed more for work than show.

The backhead has the usual fittings, along with an unusual lubricator setup. There is a separate line from the turret to the exceedingly large lubricator, with a control valve. From there, a lubricator line goes forward and connects with the steam line before the cylinders. The steam line passes through the fire for superheat, so I gather the lubricator setup is an attempt to deliver oil to the cylinders after the steam has passed through the superheater, so that carbonization of the oil does not occur. In any event, it works well. There is a Goodall-type filler valve under the cast-aluminum dome for replenishing the boiler. Side tanks are dummies.

The run

This engine is a recent arrival, so this was its first run in Colorado. It has obviously seen a lot of use. The paint work is scruffy and the smokebox interior is covered in gunge. However, the engine seems well cared for and not abused.

Firing up is routine. Since the engine is internally fired, it requires a suction fan in the stack to get pressure up. Once the gauge showed about 20 psi, I turned on the engine's blower and removed the fan. Pressure came up quickly, despite the near-freezing temperature outside. The safety let go at 60 psi and the engine was ready to go, or so I thought.

I open the throttle and gave it a push. The mechanism immediately locked up solid. The cylinders are massive and the steam instantly condensed, creating a serious hydraulic lock. I closed the throttle and pushed the engine back and forth a little, then tried it again. Same thing. It was obviously going to take some doing to heat the cylinders and get it going. After some perseverance, the engine did finally show signs of life.

I opened the throttle again and gave it another push. It reluctantly moved forward under its own power, gaining enthusiasm as it went. By the time the first lap was competed (including some inadvertent plowing of trackside snow banks), the engine was warm and lively. From there, everything was good. The run lasted around half an hour, with a couple replenishments of fuel (it's a thirsty engine). Reverse running is a little lumpy, suggesting some timing trouble. Forward running is good, though, with a loud, strong exhaust beat, even when running light. This is a satisfying locomotive to run and a good performer.

.

|

|

|

| Builder | Denis Jukes (UK) |

| Date built | Circa 1998 |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Wrighton with cross tubes |

| Fittings | Safety valve, pressure gauge, blower, throttle, check valve |

| Fuel | Alcohol |

| Blow-off pressure | 60 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Weight | 9 lb. |

| Dimensions | Length overall, 12-1/2"; width, 4", height, 4-5/8" |

.

Each component in the well-made motion work is hand crafted.

.

Left: The backhead. Steam is taken from a manifold atop the boiler. The knob at the upper right controls the lubricator, which can just be seen above the bunker at the right. The blower control is next to the pressure gauge and the throttle is to the right of that.

Above: The roof swings entirely out of the way, allowing easy access to the controls.

Slip eccentrics on the second driven axle control the valves. The rear truck is arranged around the burner, which must be removed before the truck can be taken off. The large brass block at the front end (right) is apparently for weight, helping to balance the engine.

.

Above: The fuel tank is a separate unit that just drops into the bunker. The valve in the middle of the top of the tank allows fuel to flow into the sump beneath the bunker.

Right: Pressure coming up on a cold day.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004

.