Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

November 2005

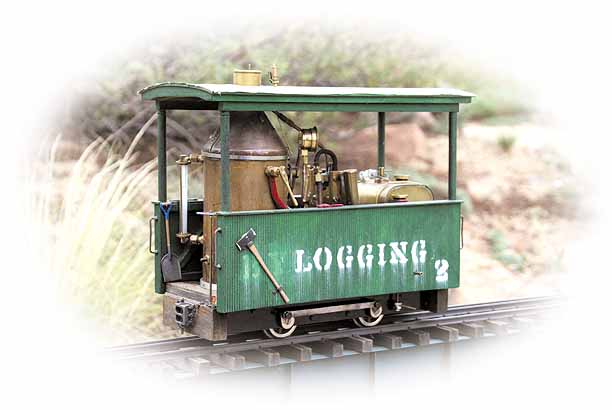

Larry Herget's 7/8" Dunkirk

by Marc Horovitz

This month's model is clearly patterned after a four-wheel, seven-ton locomotive built by the Dunkirk Iron Works (Dunkirk, New York). Only about three of these engines were made, to 3' and standard gauge, in 1882. They appear to be the first locomotives produced by the company, which was founded in 1865 to make boilers and stationary engines. The company's output of locomotives was quite small, and they evidently didn't produce anything after 1984.

The model

Here is another engine from the fertile mind of a man with too much time on his hands. Larry Herget's work, including a Porter, a freelance 0-6-0T, and a half-inch-scale logging engine, has been featured in these pages before.

As a model, it has a number of remarkable features, not the least of which is its scale. A scale of 7/8" = 1' , running on gauge-1 track, makes this a 2'-gauge model. If you've never played with 7/8" scale, try it. It's fun. The models, while still easily manageable, are big!

The engine's body is made entirely of wood and it lifts off the chassis for access to the mechanics. This locomotive has a tall, vertical boiler with three fire tubes. It is fitted with a throttle, a pressure gauge with an attractive flange around it, a water glass, a safety valve, and a Goodall-type filler valve. The boiler is held in place simply by gravity -- unscrew the steam line, release the exhaust line, and it pops right out. The steam lines are all lagged with cotton (shoe laces!).

The boiler is alcohol fired by a three-wick burner -- one wick under each of the vertical flues. The burner is supplied with fuel via a chicken-feed system and an enormous meths tank. This tank, too, is held in place mostly by gravity. It is easily removable just by lifting it out.

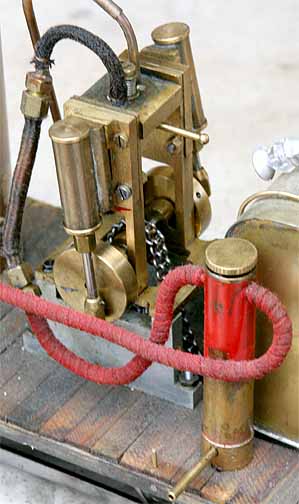

Two, double-acting oscillating cylinders, controlled by a rotary reversing valve between them, provides the power. The exhaust line returns to the stack, but is divided on its way there. Some of the exhaust is ported out the side of the engine near the bottom. The idea here is that the heavier steam oil will go out the bottom and only clean steam will be exhausted from the stack. This seems to work, as the roof was still nice and clean at the end of the run.

Pistons turn a shaft on which is a sprocket that engages a ladder chain, which in turn drives another sprocket on the axle. There is some gear reduction, but not a lot -- perhaps 1.5 : 1. The locomotive's wheels are toy-train restoration wheels with the flanges turned down.

A variety of details festoon the engine: hooks and chains, tools, a lantern, a brake wheel, a water bag for the crew, and an axe in a special bracket on an outside wall. Link-and-pin couplers are fitted to the end beams. The engine came with a pair of workman-style coaches -- spare and uncomfortable. Together, they make a pleasing train.

The run

Firing up this engine is not much different from most others. I filled the lubricator with steam oil, and the boiler with distilled water through the filler valve on the side, using a squirt bottle. I closed the valve on the fuel tank and removed it from its seat. I filled it about half full with alcohol, replaced the tank on the engine, put the loco on the track, opened the fuel valve, and lit the wicks. Run day was cold, with the temperature in the 40s. I had planned to pull the coaches, but it began to rain, so I decided not to risk them. Anyway, there were clearance-gauge issues between them and some of the trackside flora.

After six or seven minutes, the pressure was up to around 40 pounds. I opened the throttle and the engine showed signs of life. It had been a long time since it was run and, coupled with the cold weather, it was pretty stiff. However, in a little bit things warmed up and began to move. I reversed it a couple of times and finally it was off, running smoothly. I found that the engine had some clearance issues, too, but it made it around the track without too much cause for alarm.

The run lasted maybe half an hour, by which time it was raining steadily. This is a fun, easy engine to run. It is smooth and reliable and the controls are readily at hand. With the filler valve on the boiler and the alcohol-feed system, the engine could be kept in steam all day long. I look forward to better weather for another run.

.

|

|

|

| Builder | Larry Herget |

| Date built | 1999 |

| Gauge | 1 (45mm) |

| Scale | 7/8" = 1'0" |

| Boiler | Vertical, three flues |

| Fittings | Safety valve, throttle, water glass, pressure gauge, filler valve |

| Fuel | Alcohol |

| Blow-off pressure | 40 psi |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 4 lbs. 14 oz. |

| Dimensions | Length over end beams, 10-1/2"; width, 4-3/4"; height, 9-1/4" |

Below: The smokestack, a dummy whistle, and the real safety valve adorn the roof.

.

Above: With the boiler out, the burner is visible. There are three wicks, one below each of the boiler's flues. Steam lines are lagged with cotton shoe laces.

Left below: Under the boiler, the three flues are visible. The boiler is made entirely of copper, silver soldered. Even though it is internally fired, with the vertical boiler, the locomotive can be started without resorting to an exhaust fan. The flues are long enough to draw the fire.

Left: The steam motor is comprised of a pair of double-acting oscillators that drive a shaft connected to a ladder chain. The reversing valve is at the top, underneath -- you can see the handle sticking out to the right.

Above: The meths tank lifts off, just as the boiler does. This makes it easy to fill and lessens the chance of a spill around the engine. Just remember to close the valve before you take it off.

Beneath, some of the engine's construction is revealed. Under the wooden floor is a metal frame. At the left is the alcohol sump, feeding the wicks via a silicon feed tube. Below it is a lever that opens the lubricator drain. One axle is powered by the chain, with side rods transmitting power to the other axle.

.

Left: The engine at speed. It is easily controllable, will run at slow speeds, and is a good hauler. Note the wisp of steam below, coming from the exhaust extension

Above: An unfortunate incident with some overhanging foliage.

Below: With its coaches, this is an attractive train. I just wish it would negotiate my terrain.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2005

.