Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

September 2007

A pair of tram engines

by Marc Horovitz

Our Ogden Botanical Railway had no engines of its own, even though it has played host to countless "guest" engines. I wanted to come up with a "standard" design that would fit the character of the OBR, at least as it was in my mind. This is a small railway that serves just two or three communities. It hauls both passengers and light freight. Since the line is essentially level, large or heavy locomotives are not required. Also, since the length of the mainline is not excessive, smaller, lighter engines would serve just fine. Locomotives that were relatively simple in design and construction were also desirable. Tram engines, always a favorite in this part of the world, seemed to fit the bill just fine, so a basic design was embarked upon.

This basic design embodies an open, box-like cab. A transverse pot boiler, fired by two wicks, sits in the middle. A steam motor occupies the space at one end and the other end is open from the floor up. A displacement lubricator sits between the boiler and the steam motor. Beneath the footplate, at the opposite end of the steam motor, is the fuel tank. Frames are brass and body work is steel, riveted wherever feasible and bolted where it needs to come apart. Roofs are removable for internal access by the extraction of pins at either end. Externally, the two trams that have so for been built are quite similar. Internally, they differ considerably.

No. 1

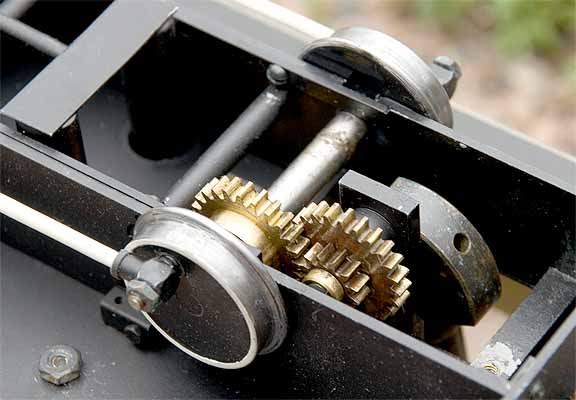

The first tram was built with one, single-acting oscillating cylinder. It is non-reversing and the steam motor is geared to the axle via a 4:1 reduction through a compound gear train. The other axle is driven via conventional siderods. Exhaust from the motor is piped directly to the stack, which comes up through the middle of the roof.

This engine is a prodigious user of steam oil, much of which ends up on the engine's roof after a run. Also, this engine, on a calm, cool day, has the unexpected but appealing characteristic of leaving a trail of perfect smoke rings behind it as it travels, something that I've never seen any other locomotive do. It runs pretty smoothly, but makes quite a bit of noise.

No. 2

Based on the success of No. 1, and given the fact that the OBR now had at least one locomotive it could call its own, the pressure for additional engines was off somewhat. Sometime later, design work commenced on another, more sophisticated version. I developed a two cylinder, double-acting steam motor that was based on another locomotive that I had built. It has a rotary reversing valve atop the motor. This is basically a stand-alone unit that can simply be dropped into place in a chassis.

The motor is plumbed into the boiler (via the lubricator) in the usual way. However, I didn't want another engine that slobbered all over itself like the last one, so I added a condenser between the exhaust port and the stack. The oil-laden exhaust steam goes first to the condenser, where the oil drops out and falls to the track via a hole in the bottom, and the remaining steam is exhausted through the stack. It works a treat.

This engine is also geared to the axle, this time 2:1. It is self-starting and runs smoothly and quietly. Because of this, it has been deemed the passenger engine.

The run

Since I'd run both engines fairly extensively and knew what to expect, I decided to double-head them today, pulling a train of 15 cane wagons. I prepared them both in the usual way, removing their roofs for access. I placed them on the tracks, lit their respective fires, and waited for steam to come up, which it did at around the same time.

Suddenly, No. 2's safety valve let go, sending out jets of water, much of which fell into the firebox, extinguishing the fire. This had never happened before (naturally). I think the safety valve must be faulty -- something I must look into. In any event, No. 2 was out for the duration.

No. 1, however, came alive. I hitched up the entire 15 cars to it and it was off. However, it couldn't keep up the pace and gradually came to a halt. I cut the train in half and the engine was quite happy for the rest of the run.

|

No. 1 |

|

| Builder | Marc Horovitz |

| Date built | 2004 |

| Gauge | 1 (45mm) |

| Scale | 15mm |

| Boiler | Pot |

| Fittings | Safety valve, throttle |

| Fuel | Alcohol |

| Blow-off pressure | 30 psi |

| Cylinders | One, single-acting oscillator |

| Reversing gear | None |

| Lubricator | Displacement |

| Weight | 3 pounds, 0 ounces |

| Dimensions | Length, 7-1/8"; width, 3-7/8"; height, 6" |

|

|

|

| Date built | 2006 |

| Gauge | 1 (45mm) |

| Scale | 15mm |

| Boiler | Pot |

| Fittings | Safety valve, throttle |

| Fuel | Alcohol |

| Blow-off pressure | 30 psi |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 3 pounds, 2 ounces |

| Dimensions | Length, 7-1/8"; width, 3-7/8"; height, 6" |

No.2 has two, double-acting cylinders that are reversed via a rotary valve. The steam is piped to a condenser that goes a long way towards keeping the engine clean.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2007

.