Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

.

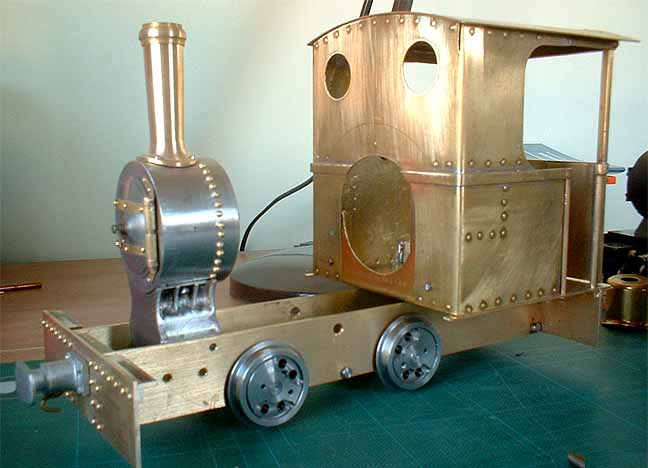

An 0-4-0 Bagnall

saddle-tank locomotive

by Bill Winter

Island of Anglesey, North Wales, UK

Photos by the author

March, 2011

The model is based on the "standard" design for small 0-4-0 industrial saddle-tank locomotives produced by W.G. Bagnall Ltd. of the Castle Engine Works, Stafford. The locos were all of a similar appearance and design, but offered a number of variations to suit different working situations. Versions were available with cylinders from 4-1/2” to 8” in diameter, and from 18” to 36” gauge. Various adaptations for European and foreign locations were offered as well as the option of coal, wood or oil firing.

Extract from the Bagnall catalogue:

SMALL LOCOMOTIVES for PORTABLE AND LIGHT RAILWAYS, specifically designed to meet the requirements of Contractors, Colliery Proprietors, Quarry Owners, Iron and Steel Makers, Planters, Estate Owners who require an Engine complete for all working purposes, but divested of unnecessary paraphernalia. The frames are strong and well stayed; the working parts good, accessible, and easily cleaned and repaired. The boiler is of special design, can be readily washed out and examined. A new firebox can be fitted in a day. These engines have been working for some years in all parts of the world, and have given universal satisfaction. Made for stock. [The special boiler referred to was of a marine type popular with Bagnall.]

-- Drawing by Dave Watkins: Used with permission

There were not many locomotives of this type in North Wales, where my line is situated, but I have found three examples. Sybil was an open-cab version on the Dinorwic Quarry. It was said to be disliked by the drivers because the fire required greater attention than the Hunslet's. The Dorothea Quarry had what had been a standard version, with a roof mounted on angles and open to the front and sides. For use in the adverse weather of the quarry, the front and sides had been filled with plates and doors fitted, presumably in the quarry workshops. The third is the one I loosely based my model on. It was supplied new with a full cab to the Llechwedd Quarry in 1899, works No. 1568. Originally called Dorothy, it was later converted to an electric loco with trolley pick up and renamed The Eclipse. The footplate was stepped down at the rear to allow for a lower roofline, presumably to suit the loading gauge in the quarry -- something I have not copied.

The model

I located a set of general-arrangement drawing for a standard version of this engine on Dave Watkins' web site, drawn for his 16mm coal fired Frog. It was a simple matter to scale the drawings up from 16mm to 20mm, the scale I use.

Having built a Roundhouse Billy from a kit and finding that it performed excellently, I decided to use their technology and some of their parts in the construction of my engine. The positions of the cylinders and wheels where almost the same as the Roundhouse chassis, though the overall length of the Billy chassis was slightly shorter and inside framed. My loco was to run on 45mm track, representing 2' 3”, so the reduced space between the frames did not cause too much of a problem.

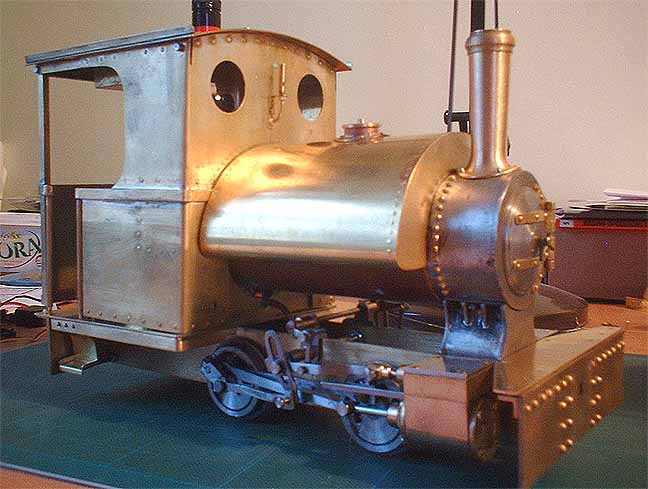

The loco uses Roundhouse cylinders, burner, and gas tank, with wheels from the Basic series locos. The remainder was built from scratch. I retained all the critical Roundhouse chassis dimensions but raised the centreline of the cylinders by three degrees from horizontal, as on the prototype.

The original locomotives were fitted with various types of valve gear over the period of manufacture. I elected to stick with the proven Roundhouse design. I did consider using some dummy rods to make a more accurate representation of Bagnall Price gear but decided that they would hardly be visible and a potential source of problems.

The boiler is a conventional single flue, gas-fired type. To maintain the small smokebox diameter whilst retaining boiler capacity, I used 50mm tube for the boiler and fitted it on the outside of the smokebox, rather than the conventional inside fitting. When the saddle tank is in place the extra diameter is not obvious. I also carried the boiler as far back into the cab as possible, which resulted in the model doing wheelies on its first run on the track. A block of lead was cast and fitted behind the front beam to cure this unseemly behaviour.

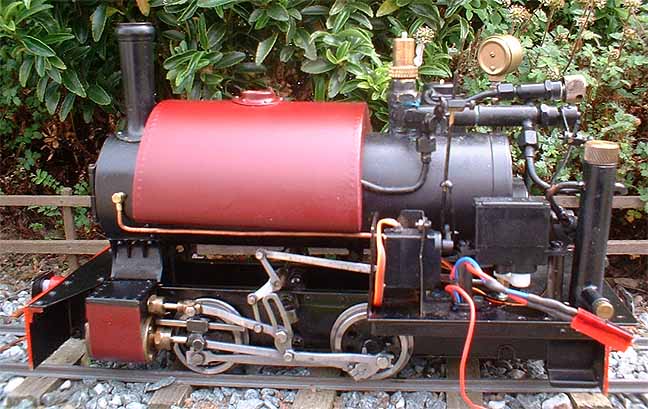

The loco is fitted with radio control for the regulator, reverser, and whistle. Servos are all in the cab, the batteries are in the roof, and the receiver is under the cab, between the frames.

The first run

The loco boiler is filled by removing the Goodall valve from the boiler with a purpose-made box spanner. The gassing, lubrication, and firing is carried out in the usual way.

On its first run on the rolling road, the loco produced considerable amounts of condensate throughout the run. A consultation with the experts on the SteamModelLoco Yahoo group suggested the problem was caused by cooling of the steam in the external steam pipe and/or contamination of the water by residues from the silver brazing. Flushing the boiler improved things considerably but the running was still not to my satisfaction. In the end I stripped the loco and rerouted the steam supply through the flue, brazing a length of stainless tube into the centre section.

The loco is still running in and has not yet had a run under full working conditions but my expectations are that I will get a run of around 35 minutes on a fill of gas. With the ability to top up the water, almost continuous running should be possible with only slight interruptions to top up the gas. The loco is now running better than my Roundhouse did when first built so I am quite pleased with the result.

|

|

|

| Builder | Bill Winter (UK) |

| Date built | 2009-2010 |

| Gauge | 45 mm (gauge 1) |

| Scale | 20mm to the foot (approximately!) |

| Boiler | 50mm x 150mm outer with a single 18mm flue |

| Fittings | Regulator, whistle valve, Goodall valve, pressure gauge, safety valve |

| Fuel | Butane gas |

| Blow-off pressure | 40 psi |

| Cylinders | Standard Roundhouse 9/16”-bore with D-valves |

| Reversing gear | Simplified Walschaerts |

| Lubricator | Displacement |

| Dimensions | Length, 10” (ex buffers); width, 4-1/2”; height, 7” |

| Weight | 7 lbs. 4 oz. (incl. 1/2 lb. of lead) |

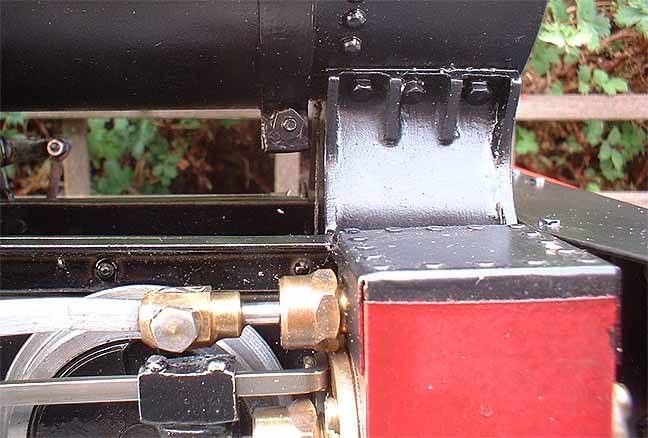

Right: The backhead with the cab removed. On the left side of the footplate is the displacement lubricator. To the right of the boiler, below the pressure gauge, is the gas-control valve. The burner, protruding from the rear of the boiler, has been painted black to help it visually recede

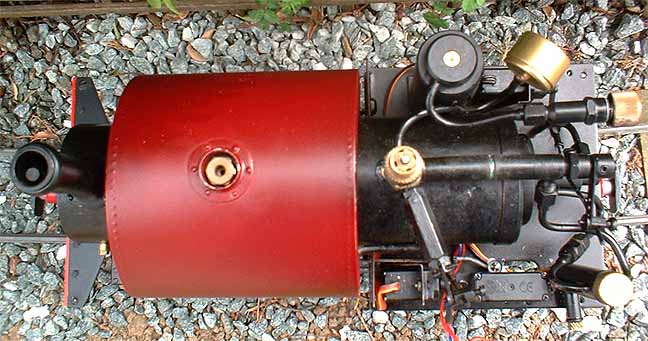

Below: Looking down on the engine. The Goodall valve is in the saddle tank.

Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

This page and its contents

Copyright Sidestreet Bannerworks, 2011