Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

.

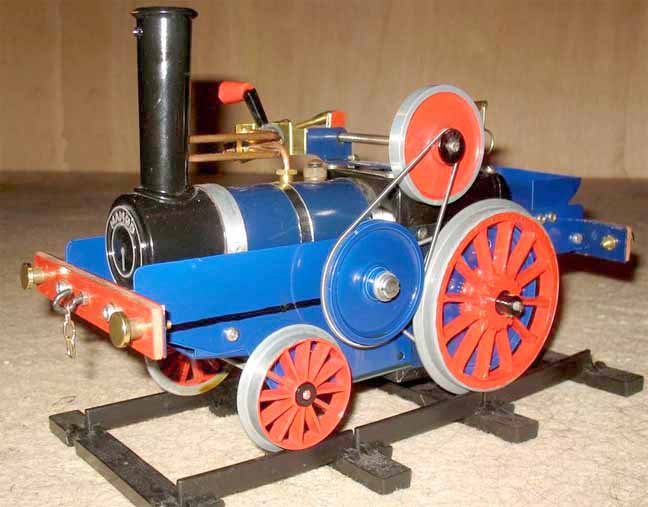

Aveling & Porter Blue Circle

by Roly Williams

Lambourn, West Berkshire, Great Britain

Photos by the author

August, 2011

The prototype is the Aveling & Porter (A&P) 2-2-0 GWT Blue Circle. It was built in 1926 and first used by Holborough Cement Co. Ltd. at Snodland Cement Works (Blue Circle Cement). It was retired in the early 1960s, when it went to the Bluebell Railway, where it remained until recently. It is now resident at the Chinnor and Princes Risborough Railway.

Aveling & Porter (amongst others) built several small shunting / tram locos based on their traction engines. They were basically traction engines with flanged wheels and no steering. Their advantages were that they were cheap to manufacture (and to design in the first place) and they could be operated with minimal training by someone who was familiar with traction engines.

The model

This is not a serious model, by any means. I think of it as a toy, based loosely on the Blue Circle. Like the original, my version is also based on an existing traction engine -- in this case the Mamod TE1A. I had most of the parts required in my spares box. The boiler, firebox, smokebox, and engine are from the Mamod. After some searching, I eventually acquired a set of 3.5" gauge wheels, originally from a Hornby Rocket, which are just about the right size. The small ones easily fit onto a Meccano axle. I have fitted bushes to the large ones so that they, too, fit. The main frames are scratchbuilt. As it happens, the Mamod firebox is just about the right width for me to maintain the 3.5" gauge.

There were several possible alternatives for the drive:

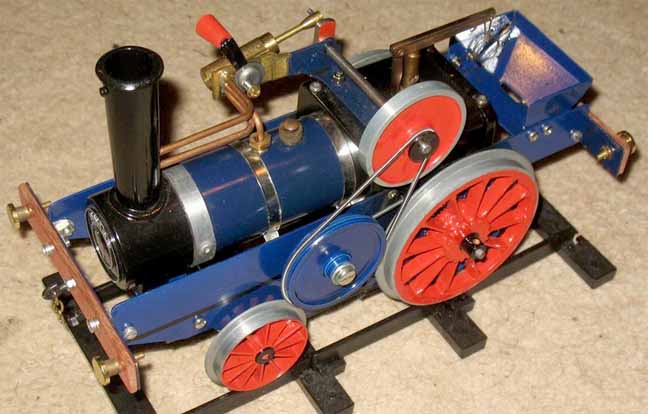

* Pulleys and belts, as per the original Mamod

* Gear train, as per the original Blue Circle

* Sprockets and chain, as seen on some other A&P examples.

Mainly because of clearance constraints between the rear wheel and firebox, I decided on the pulleys and belts option, with an intermediate pulley to give a two-stage speed reduction down to a fairly realistic scale speed. (The traditional, direct belt drive from crankshaft to wheel, as found on the Mamod and others, gives an unrealistically high speed and not much pulling power.) The intermediate pulley is taken from a Mamod SW1 steam wagon. The final drive is to a Meccano 3"-diameter pulley mounted on the main rear axle. Even using this option, I still had to shave a bit off the Mamod firebox to get enough clearance.

Because the Meccano axle is a smaller diameter than the original Mamod one, I have fitted a couple of brass bushes to the firebox sides, attached to the inside. These also give somewhat better bearing surfaces. This is important because the new wheels are both fixed to the axle (as per standard railway practice), so that the axle rotates in the bearings. (The original Mamod wheels were free to turn on the axle, which probably remained stationary most of the time.) I realized, after I had done this, that the firebox sides are slightly tapered, so that the holes in the two bushes didn't line up with each other. This meant that I had to do a bit of metal bashing to line them up.

I cut the frames from mild-steel sheet, using a hacksaw blade in a power jigsaw, and three files of varying coarseness. I rather regretted choosing 1mm-thick steel while I was doing this but I'm glad I did, now that it's done. The frames are nice and rigid!

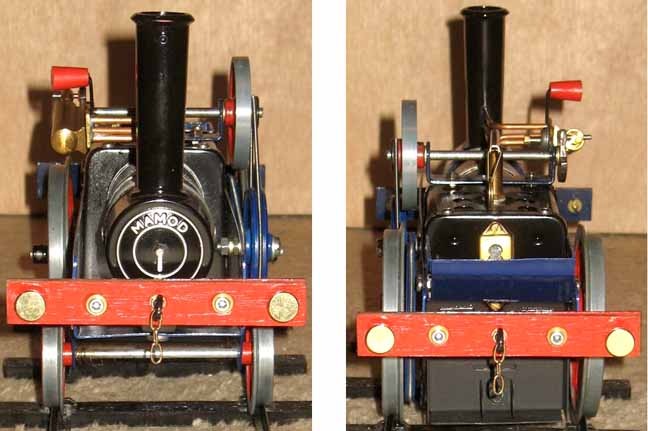

I modified the Mamod "scuttle," cutting it in half and fixing the top half to the frames, turned over so that it looks a bit like the bunker on the prototype. The burner is attached to the bottom bit, screwed in place, with the handle removed -- like the early Mamod SR1 steam roller.

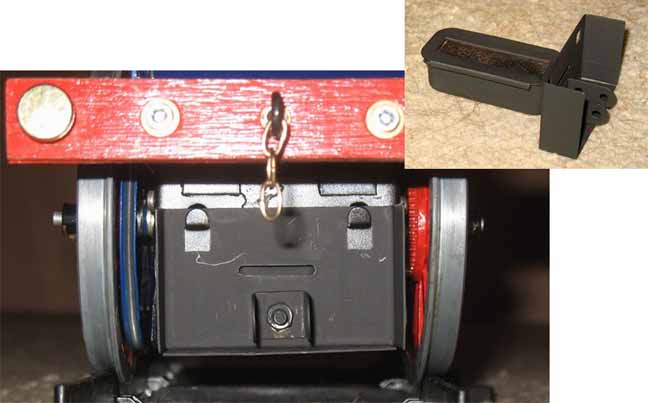

Buffer beams are wood, backed with steel for strength. By luck, I just happened to find a couple of suitable threaded hooks, to which I added short bits of clock chain for couplers. The buffers themselves are made up from mirror fixings and mains plug pins (the old fashioned 15 amp, round-pin variety -- how many of you remember those?). The boiler bands were cut from a tin can -- not a perfect match for the mazak one on the Mamod smokebox but closer than the commonly available brass ones would be.

I painted the loco in a livery similar to the prototype, mostly blue and red. I used VHT (high temperature) paint, which behaved in a rather strange way. It's OK on the boiler and frames but, on the firebox, which is exposed to the direct heat of the flames of the meths burner, the blue paint immediately turned black on the first firing. There was no detriment to the semi-gloss finish but all colour disappeared! Oh well, it still looks OK. When fired up for the first time, the boiler primed like mad and the engine was rather rough, so it didn't run at all well. However, with a bit of running in, both problems soon disappeared. It ran better every time I fired it up.

A typical run

Now that the initial teething problems have gone, it is now a reasonably good runner. Firing up is basically the same as with the original Mamod traction engine. For convenience, I use a large syringe to fill the boiler with distilled water (actually from a dehumidifier). My tap water is too hard for use in boilers. Water level is visible in the sight "glass" (actually plastic).

The burner is a Mamod "vapourising" meths burner, which I fill using another syringe, pouring any excess back into the bottle. After lighting, the burner is a bit tricky to get into place without extinguishing the flame, but it is possible. If I fill the boiler with hot water, it only takes a couple of minutes to get up to working pressure.

I use the time to oil up the moving parts. I use thick steam oil in the cylinder and 3-in-1 for the rest. There are no proper lubricators so oiling is manual, from a can.

Once the safety valve shows signs of lifting, one or two flicks of the flywheel is usually enough to get going. Sometimes a bit more is required if it has been left standing for a long time or if I overfill the boiler, causing priming. It runs for about 10 minutes before the fuel runs out in the burner (well before the boiler runs dry).

Click here to visit Roly Williams' web page about this engine.

Below is a video of a verbal description of this engine and a demo of it running.

If, for some reason, you can't view it, click here.

|

|

|

| Builder | Roly Williams (UK) using parts from Mamod, Hornby, Meccano, and some scratchbuilt parts |

| Date completed | 2009 |

| Gauge | 3-1/2" |

| Scale | 1:16 (approximately) |

| Boiler | Pot, with vapourizing meths burner |

| Fittings | Standard Mamod safety valve, whistle and sight glass |

| Fuel | Alcohol |

| Blow-off pressure | 15 psi (approximately) |

| Cylinders | One single-acting oscillator |

| Reversing gear | Lever shifting the cylinder trunnion |

| Lubricator | Oil can |

| Weight | 1.8 kg in working order |

| Dimensions | 11-1/2" between buffers; 7" from track to top of chimney. Boiler ,1-3/4" diameter x 6" overall length (somewhat shorter inside!). Cylinder, 5/16" bore x 3/4" stroke. Driving wheels 3-1/2" diameter |

Below: The cylinder is a single-acting Mamod oscillator. The red lever in the upper right corner of the picture reverses the engine realigning the cylinder with the steam ports.

Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

This page and its contents

Copyright Sidestreet Bannerworks, 2011