Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

.

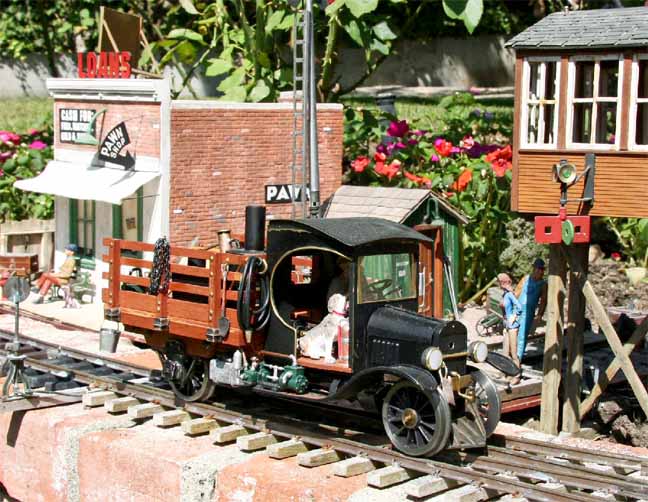

(Photographed by Rick Parker on Sony Wizelman's railway.)

A live steam, Model T,

stake-side railtruck

by Howard Maculsay

Claremont, California

Photos by the author unless otherwise noted

October, 2011

In building my steam-powered railtruck, I was originally inspired by Matilda, a steam-powered truck I first saw at the Diamondhead steamup in 2008. Matlida was built by my steam-up friend, Sonny Wizelman. When I saw him at the next steamup, I got a most helpful first-hand view of his creation.

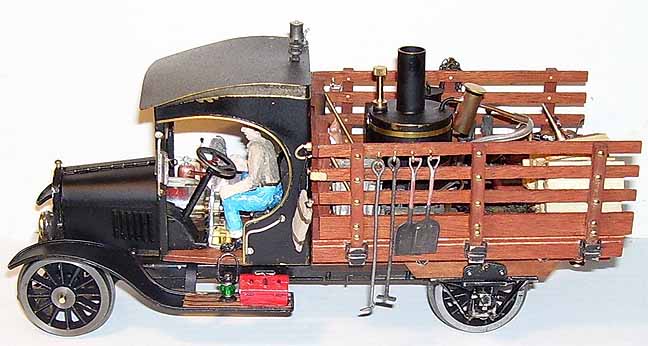

I made the decision to keep as close to a 1:20.3-scale Model-T as I could. My research eventually took me to the August. 2004 issue of Garden Railways magazine, specifically Ted Stinson's plan for a 1927 Model-T oil truck. I obtained the plans from Sidestreet Bannerworks. All of this led me to Northeast Narrow Gauge's (NENG) Tin Lizzy series of kits. They had a 1927 Model-T stake-side truck that was right in line with what I had envisioned.

At this point I didn't have any evidence that the Model-Ts were used on the rails but I finally ran across this video from the Ford Motor Museum, which showed a Tin Lizzy out on the tracks.

Of course I wanted to make my Model-T steam powered, so my primary task was to find steam components that would fit the dimensions of the 1:20.3-scale truck. Again, Sonny Wizelman came to the rescue with his little Lutz Hielscher “Pepper” locomotive's steam components, which he no longer needed. Needless to say, we made a deal. That's how it all started, now I could get on with the design.

The model

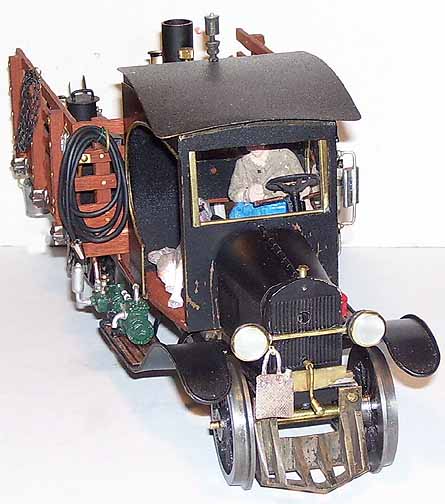

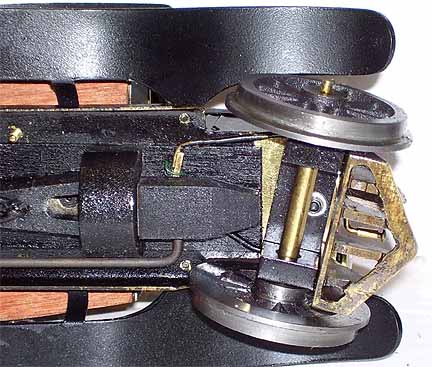

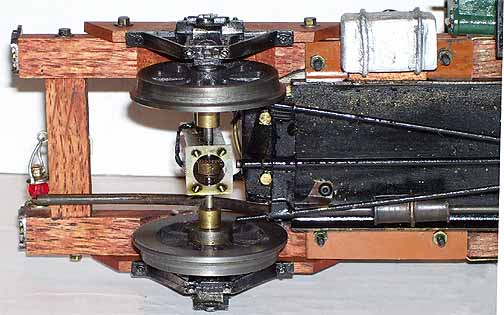

The primary undercarriage is made from brass, while the truck bed is sits on an oak frame. The boiler, burner, and butane tank are isolated from the brass frame by an insulation layer made from circuit -board material. This prevents the boiler and burner heat being transmitted throughout the brass undercarriage.

The cab and hood are all brass and are easily removed as a unit. The 2”-tall stake sides of the truck bed are walnut and the 5-1/8” long x 4-1/4” wide truck-bed floor is laser-scribed plywood.

I used the radiator, steering wheel, and headlight castings from the NENG Tin Lizzy kit. The four, 12-spoke wheels are castings from Sulphur Springs, turned down to replicate the wood-spoked wheels in the NENG kit.

Power comes from a single cylinder, single acting, oscillating steam motor. The steam motor is integrated with a geared drive train containing a flywheel and six gears, to achieve a 40:1 reduction. The final gear in the train is on the rear axle, which sits in ball bearings mounted in the journal boxes.

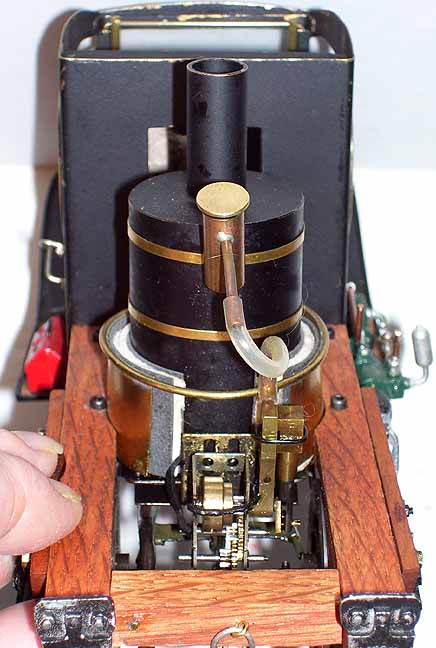

The 1-3/8”-diameter boiler is 2-1/8” tall (plus a 1-1/16”-tall chimney). It has a single, L-shaped, 3/8”-diameter flue. The blow-torch-type burner sits just outside the flue and shoots a nicely-shaped flame into the flue. Butane is housed in a 1-3/8” long x 7/8” wide x 1-/1/8” tall plastic pressure vessel that has a Ronson-type filler valve and a self contained fuel-shut-off and gas-flow needle valve. It also has an integrated, flexible gas-feed hose with a jet attached.

Initial testing and first public outing

My initial firing was with the truck up on blocks. The butane tank was filled to just over half full. Since the tank lays on its side, the liquid level must be kept below the gas outlet, and to allow the liquid butane space to gasify. I only filled the boiler with 20ml of water (instead of the 30ml specified) to allow for steam space.

After I filled the lubricator and lubed the steam motor, gears, and wheel bearings, I fired it up. In about five or six minutes steam and bubbles started to appear in the tubing leading to the steam motor. I flicked the flywheel in the correct direction a few times and it took off.

It sounded like a bumblebee. It ran, as advertised -- 15 minutes -- but not under any load, so I could expect something under 15 minutes run time when it was on its wheels on the track.

I used the second run to calculate the model's potential speed on the track. The drive wheel turned 135 times in one minute. At 135 rpms, with a 40:1 gear reduction, the result is over 5,000 rpm at the steam-motor end. That's what generated the bumblebee sound. So, when considering the wheel diameter, the model's scale speed is around 12 mph. Not bad!!

My next test was on my home test track in preparation for a trip to the 2008 National Summer Steamup (NSS) in Sacramento , California in July of that year. You can see a video of it here. The first public outing was at the 2008 NSS. You can see videos of it running at the NSS here and here.

|

|

|

| Builder | Howard Maculsay |

| Date completed | 2008 |

| Gauge | 45 mm (gauge 1) |

| Scale | 1:20.3 |

| Boiler | Vertical, with a single L-shaped flue and a blow-torch-type burner |

| Fuel | Butane |

| Blow-off pressure | 15 psi (approximately) |

| Cylinders | One, single-acting oscillator with 40:1 integrated gear train; piston dia., 3 mm; stroke 5 mm |

| Reversing gear | None |

| Lubricator | Displacement |

| Weight | 2 lbs. 9oz., dry |

| Dimensions | Length, 10-1/4“; width, 4-1/4“; height , 5-1/4“ |

You can also see how the oak truck-bed frame is protected from the heat of the boiler. The brass surround contains two layers of high-temperature gasket material sandwiching white ceramic-insulation material.

Silicone tubing is used to connect the steam line to the steam motor.

Louvers were cut using custom-made hard tooling. Wheels are 12-spoke, cast iron, lost-wax castings, turned to the dimensions of the Model-T's wood-spoked wheels.

Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

This page and its contents

Copyright Sidestreet Bannerworks, 2011