Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

.

A home-built Shay

by Jerry Barnes

Lexington, Nebraska

Photos by the author

September, 2010

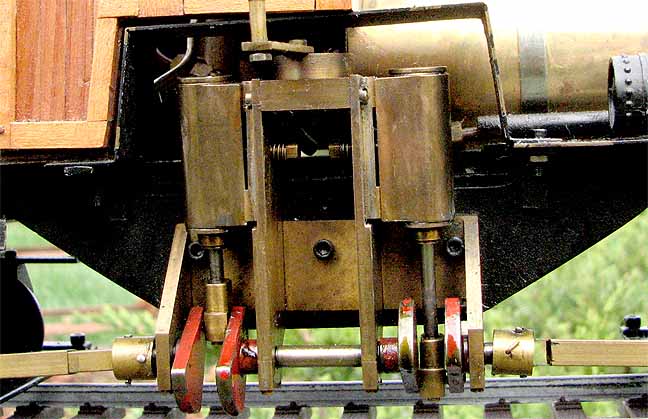

I made the trucks from brass, using Chicago Gears and Sierra Valley wheels. The U-joints I made from brass tubing. A small brass tube is mounted crosswise on each end, held in place with sewing pins that I beveled somewhat for a tight, interference fit. They stayed on all these years!

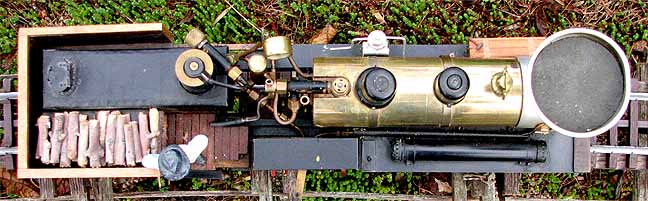

The frames are made of brass, too, with wood end beams. I made a cab of wood. Detail parts on the boiler and elsewhere came from Trackside Details and Ozark Miniatures. I try to keep the detail level down, since I seem to knock them off all the time. The smokebox is a Roundhouse SR&RL No. 24 part that I got when I bought a Roundhouse boiler and fittings from a dealer in Maine (no longer in business). I used a funnel for the stack, as you can see.

This is a very easy engine to fire and run. The Roundhouse boiler and fittings have been great. It lights right up, the fire usually flashing back to the burner with no problem. Pressure comes up in about 10 minutes (I usually start with distilled water warmed up in the microwave).

The engine will start off with as little as 10 lbs of pressure and that is about what I run it at. I really like the oscillating motor that Mike Chaney made for me. It runs like a sewing machine and I love to watch its action. I usually get about 30 minutes or so from a run.

Here's a movie of the Shay in action.

If, for some reason, you can't view it, click here.

|

|

|

| Builder | Jerry Barnes |

| Date built | 1996-1998 |

| Gauge | 45 mm (gauge 1) |

| Scale | 1:20.3 |

| Boiler | Single flue made by Roundhouse |

| Fittings | Safety valve, pressure gauge, throttle |

| Fuel | Butane |

| Blow-off pressure | 30 psi |

| Cylinders | Two, double-acting oscillators made by Mike Chaney |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Dimensions | Length, 18" |

Below: The "other" side. A water reservoir surrounds the Roundhouse gas tank.

Above: The steam motor, a twin, double-acting oscillator, was built by Mike Chaney. The reverser is the lever atop the motor.

Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

This page and its contents

Copyright Sidestreet Bannerworks, 2010