Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

.

Hank Povee's Norris 4-2-0 engines

by John Riley

Rockledge, Florida USA

Photos by the author

January, 2011

The prototypes

Three of the Norris brothers were involved in locomotive production at Philadelphia: William, the promoter, who was forced out when the company failed in 1841; Septimus, the engineer; and Richard, the shrewd and successful business manager under whom the business prospered. Norris offered four engines, sized from 7-1/2 to 15 tons, each with the 4-2-0 wheel arrangement. These were marketed in the US and Europe from 1838 to 1845. Lafayette, built for the B&O in 1837, was a typical Norris 4-2-0, about 20 feet long (30 feet including the four-wheel tender), it had a gross weight of 20 tons, 10-1/2 x 18" cylinders, and four-foot driving wheels. A Norris engine of this type demonstrated its ability to haul a train of cars weighing 200 tons up a 1% grade, a considerable feat for the day.

The models

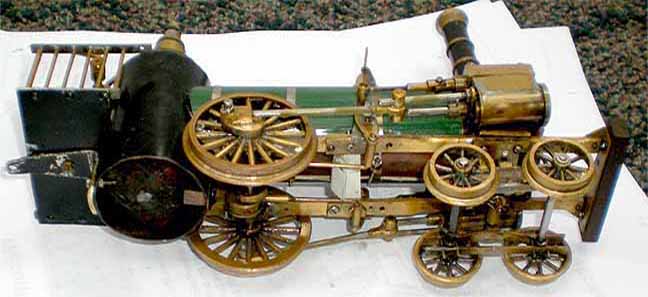

Both engines have gas fired, single flue T-boilers of 100 ml. capacity. The engines are minimalist in design. Reversing gear, regulator (throttle), sight glass, and pressure gauge are not to be found. The backheads of the engines support only the safety valve, blowdown valve, and the displacement lubricator. Steam is taken from the top of the dome. The steam pipe runs through the boiler and exits in the smoke box, where a T-pipe connects to the cylinder valve blocks.

The engines are capable of fine speed control through regulation of the propane supply to the burner. A small propane tank is carried in the tender. Fine regulation of the gas supply is achieved by a needle valve with a 3-56 thread and a two-degree taper. A short piece of silicon tubing connects tank to burner.

Hank built his own safety valves, gas jets, gas-control valves, gas tanks, boilers, and spoked wheels. A close up of Norris II, still oil covered after the run, shows the detail of the drivers -- each built up of 21 pieces soldered together -- and the truck wheels, each of 11 pieces.

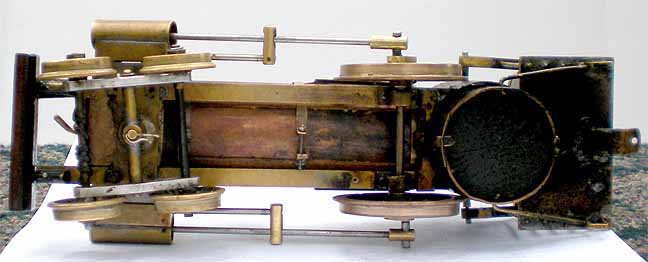

The bottom views show the difference in the motion of the two engines. Norris I is a single-acting oscillator. Norris II is a piston-valve engine, with the piston valves driven through eccentrics on the drive axle via rocker arms.

The run: Norris I

These runs took place on one of the elevated gauge-1 tracks at Larry Smith's Manatee Central Railroad in Parrish, Florida. The day of the run was sunny, in the low 80s, with a pleasant breeze -- typical April weather for west-central Florida.

The engine was oiled all around, the lubricator filled with steam oil, and the boiler filled with water to the top of the horizontal tube. The propane tanks for the Norris engines are fabricated from 1" diameter, thick-walled copper tubing. The filler is a Shraeder valve; the output of the tank is metered through the fine-control needle valve and fed to the burner via small-diameter silicon tubing. The burner is lit through the smokebox front. Hank set his burners for a small flame and raised steam very slowly in his engines. A rake of small, four wheel, hopper-bottom cars is attached to the engine After seven minutes, steam pressure was high enough to run. With the help of the hand from above the engine was rolled along the track until condensate cleared. The Norris then set off on its own at a brisk pace. The train continued circuit after circuit of the elevated track for 30 minutes.

Hank's engine operation is very economical of fuel and steam. No safety valve blowing off and no howling gas burner here. As a result, his engines are capable of runs in excess of 30 minutes with no provision for adding water to the boiler while under steam.

The run: Norris II

Norris II was run the following morning. The air was a bit cooler, in the low 70s, with a few drops of fine rain. The usual preparations were completed. The gas tank was not cooperating with attempts to fill it so the gas tank and tender from Adler, another of Hank's engines, was pressed into service and the fire was lit. After about seven minutes steam pressure was high enough for operation. The engine was rolled back and forth to clear condensate and, like its sister engine, set off on its own (at a slightly slower pace than its sister engine), trailing Hank's string of four-wheel cars. The run lasted 35 minutes before the engine ran out of gas.

|

|

|

| Builder | Hendrik “Hank” Povee, New Port Richey, Florida |

| Date built | 2000-2001 |

| Gauge | 45 mm (gauge 1) |

| Scale | 1:32 |

| Boiler | Single-flue T |

| Fittings | Safety valve, blow down valve |

| Fuel | Propane gas |

| Blow-off pressure | ~35 psi |

| Cylinders | Single-acting oscillators (Norris I); Double-acting piston valve (Norris II) |

| Reversing gear | None |

| Lubricator | Displacement |

| Dimensions | Length 8.5"; width, 3"; height, 4.6" |

| Weight | 777 grams (Norris I engine); 815 grams (Norris II engine); 272 grams (tender) |

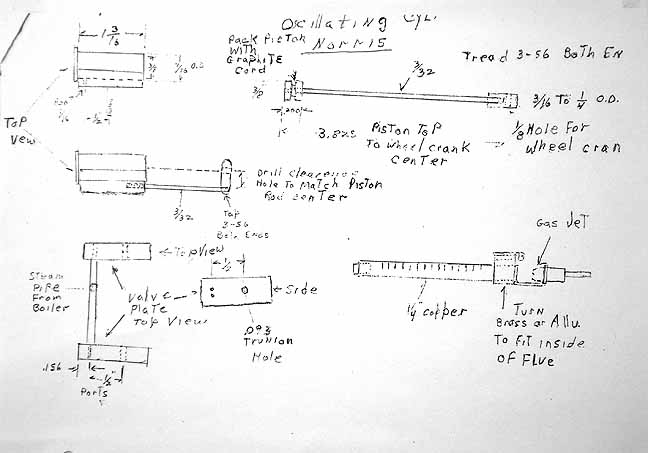

Below: The details of the oscillating cylinders, port blocks, and poker burner.

Back to Sidestreet Bannerworks

Click here to find out how your engine can be featured!

This page and its contents

Copyright Sidestreet Bannerworks, 2010