Back to Sidestreet Bannerworks

February 2001

Archangel 2-6-2T Taw

by Marc Horovitz

The history of Archangel Models was covered in our October, 2000 Locomotive of the Month, so I won't go into it here. Taw, the locomotive after which this month's engine is modeled, ran on the Lynton & Barnstaple Railway in Devon, in southern England. The L&B existed from 1898 to 1935. It was purchased by the Southern Railway in 1923, which ran it until it closed.

Taw was one of three similar engines (the other two were Exe and Yeo, all named after rivers) supplied to the railway by Manning, Wardle & Company of Leeds.

The L&B had very high standards as far as equipment is concerned, including a large assortment of beautiful coaches, since it was primarily a passenger-hauling line. The L&B has been compared to the Denver & Rio Grande, as regards the high degree of interest in it among enthusiasts and the intense loyalty of its followers.

The engine

This model, which was made during a period that might be considered the company's peak, follows typical Archangel practice. It is robust and well made. While nicely proportioned, its proportions do not necessarily closely match those of the prototype. Detail is minimal, but the important bits are there—large, brass dome; sand boxes; and the safety valve in the oversize cab. Under the dome is a removable plug for filling the boiler.

The engine uses Hackworth valve gear, controlled from the cab, whereas the prototype had Joy gear. On the left side, there is a whistle under the cab, operated by a screw valve. On the other side is a blowdown valve. A displacement lubricator is mounted under the broad pilot deck, with the nylon filler cap protruding through the deck plate.

The boiler is a large, pot boiler fired by a three-wick alcohol burner. Fuel is carried in a tank in front of the rear buffer beam. The burner, at fist glance, appears inadequate for such a larger boiler, but it is not.

This particular engine is fitted with an RCS radio-control system. When getting the engine ready to run, I discovered that the valve-gear servo wouldn't work, so I had to reverse it manually.

Performance

It was a dull, cold February day when I took Taw out to run it. Temperatures were in the 30s. It had snowed some days previously, so I had to scrape the tracks the day before the run to let the sun do its work. By track time, the right-of-way was clear. Moving parts were oiled all round, the lubricator filled, the engine fueled and watered, and the three small wicks lit. Pressure showed on the clock in less than five minutes. I am always amazed at these engines' efficiency.

Once the gauge showed 40 pounds or so, I opened the R/C throttle. After a couple of jerky revolutions of the drivers, the engine took off. No need to push this one. It was very responsive to the RCS radio (throttle only), and would easily creep along or take off faster than I was comfortable with.

I gave the whistle a toot just to try it out (I'd not tried it on previous runs) and was pleasantly surprised. While the tone was predictably high pitched, it was clear—not bubbly or breathy.

I manually pushed the reversing servo into reverse and the engine performed just as well going backward as forward. Like most of Archangel’s larger locomotives, this one is easily controllable and smooth running. Running light, it was nearly silent, except for the punctuation of its typically Archangel, rude-noise safety valve (I've never heard another like it).

The run lasted a good 40 minutes, by which time the fuel was exhausted and my feet were too cold to continue. When it comes to cold-weather running, an alcohol-fired engine is hard to beat. This one is a favorite. It embodies everything I like to see in a small steamer—strength, reliability, predictability, and smoothness of operation.

| Specifications | |

| Builder | Archangel Models, Great Britain |

| Date built | July, 1982 |

| Gauge | 32mm (gauge 0) |

| Scale | 16mm |

| Boiler | Pot boiler |

| Fittings | Safety valve, throttle, pressure gauge, whistle, blowdown |

| Fuel | Alcohol |

| Blow-off pressure | 70 psi |

| Cylinders | Two, double-acting D-valve cylinders |

| Reversing gear | Hackworth, controlled from the cab |

| Dimensions | Length over buffers, 16"; width, 4-1/4"; height, 6" |

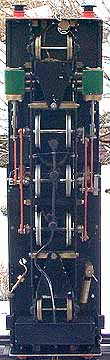

Left: Underside of the engine. Note how the fuel line is bent to clear the trailing-truck connection.

Right: A head-on view. The nylon lubricator cap is below and to the right of the smokebox door. These were often painted black, but the paint never stuck to the nylon very well.

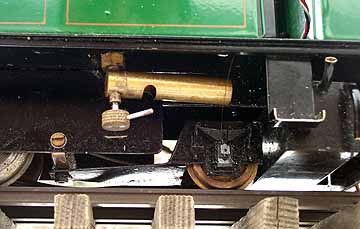

Above right: The whistle is controlled by the little handle on the valve. Only about 90 degrees of turn is required to get the whistle to sound its pure, high-pitched note.

Right: The cab is spacious and spartan. Speed is controlled by the left-hand servo while direction is governed by the right (when it is working).

Lower right: The blowdown valve is used to relieve boiler pressure (and vacuum, upon cooling) at the end of the run. The valve is not supported by anything aside from the copper line to which it is attached.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2001