Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

October 2008

Bassett-Lowke's Mogul

by Marc Horovitz

One of the most popular and successful locomotives ever produced by Bassett-Lowke was its 2-6-0 for gauge-0 track. Introduced in 1925, the engine was produced for around three decades and it was briefly reissued in 1968, when a batch of 100 were made. This locomotive was offered over the years in a wide variety of liveries and railway names, with appropriate cosmetic detail differences. It was offered in clockwork, electric, and live-steam versions, but the steam ones are the most common. It was, for a while, even offered in kit form. Corgi, who now owns the Bassett-Lowke name, issued a made-in-China exact replica of the Mogul in steam in at least two liveries.

The model

The version shown here is black, lettered for the London & North Eastern Railway. Construction is generally tinplate, painted and nicely lined and lettered. The brass boiler is a pot-type of the low-pressure variety. It is fired by one of Bassett-Lowke’s effective vaporizing-spirit burners, held in place by a simple wire clip under the cab.

Atop the boiler is a toy-type safety valve. Over this rests an ornamental steam dome. As this small, light piece relies on gravity to keep it in place, it is frequently lost. On the backhead is mounted a tiny whistle with a lever. The whistle protrudes through the cab roof.

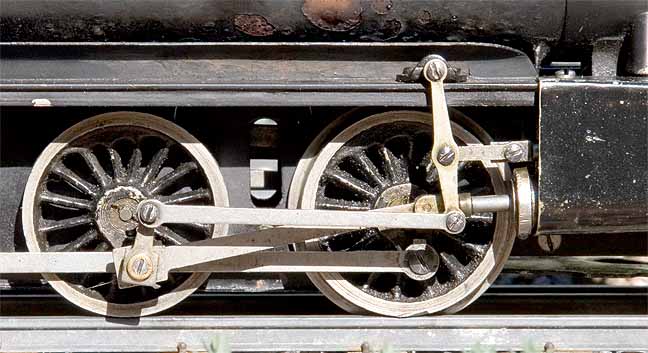

Spoked wheels are all cast and all of the rods are stampings. The nicely proportioned tender serves no functional purpose, but simply trails along behind. It has a drawbar with a pin on it that engages a loop on the locomotive, close-coupling one to the other There is the added attractive feature of an apron that folds down over the drawbar, resting on the footplate of the cab.

Cylinders are fixed, controlled by piston valves. Reversing is via a rotary valve, actuated by a lever in the cab. This lever also protrudes through the cab roof, through a slot that is notched to lock the lever in the center, neutral position, presumably as a safety measure.

The smokebox pulls off to reveal a large displacement lubricator with a pair of filler plugs. You remove both plugs and fill the lubricator with oil until it comes out the other hole.

The run

This is an old, well-worn engine, so I decided to try it on air first. It didn't go, although one side showed signs of life. Aside from just wearing out, there's not a lot that can go wrong with these engines. I suspected valve timing.

All the linkages are fixed, as far as any adjustments that might be made. The only thing that can be changed is the angle of the eccentric (return) crank. The crank has a square hole in it that registers on the square end of the crankpin. A screw holds it in place. The only way to change the setting is to rotate the crankpin.

The crankpin is screwed into the driver and a lock nut retains it. By loosening the lock nut, the crankpin can be moved to a new position, when the lock nut is then retightened. By a process of trial and error I arrived at valve settings that seemed pretty good. Next, the steam test.

I prepared the engine in the usual manner and lit the vaporizing spirit burner. When this is working, it makes a very soft hissing sound. After five or six minutes on this warm, still, cloudless day, steam came up. I pushed the lever forward, then gave the engine a shove to clear the cylinders. In a little bit, it moved off by itself, although with little enthusiasm. I could hear a pronounced hissing from the front end, suggesting a steam leak somewhere.

I closed the throttle and let the engine sit for a few minutes, then opened it again. It started out with alacrity, but soon lost confidence and slowed. However, it did manage to limp all the way around the track a couple of times before completely running out of puff. Once the steam leak is cleared up, I think this will be a good runner.

|

|

|

| Builder | Bassett-Lowke Ltd. (UK) |

| Date built | Late 1940s (?) |

| Gauge | 32 mm |

| Scale | 1:48 |

| Boiler | Pot |

| Fittings | Safety valve, whistle |

| Fuel | Alcohol |

| Blow-off pressure | 15 psi |

| Cylinders | Two, double-acting piston-valve |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 3 pounds, 1 ounce (loco and tender) |

| Dimensions | Length over end beams (loco and tender), 16-3/4"; width, 2-1/2"; height, 3-3/4" |

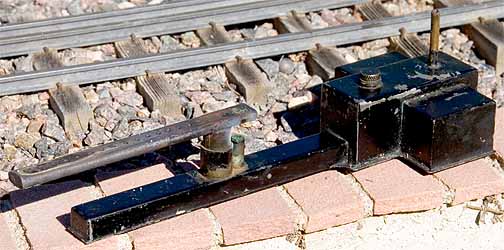

Right: The large displacement lubricator is accessed by pulling off the smokebox. There are two filler plugs. Remove them both and fill through one hole. When it overflows out the other, it's full.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2008

.