Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

December 2008

Harvey Watkins' Finescale GVT tram

by Marc Horovitz

The Glyn Valley Tramway was a 2' 4-1/2"-gauge line, originally built in 1873 as a horse-drawn line to carry slate in northern Wales. The railway grew and began to carry other goods, as well as passengers. The line was rebuilt and reopened in 1888, this time with steam power. Sir Theodore (after Sir Theodore Martin, a one-time chairman of the line) was one of the first two original engines on the line and one of four that the railway ultimately owned. The line finally closed in 1935.

Sir Theodore was built by Beyer Peacock in 1888 and was scrapped in 1936, after the line closed. It was an 0-4-2, built to tramway specifications (three of the line's four engines were built to this pattern), which meant that all fire and motion work was hidden behind the skirt that surrounded the engine. Noise was eliminated as much as possible, and a bell was used to announce the engine's approach. These engines usually ran cab first, to afford the driver a better view.

The model

Finescale Engineering made a model of Sir Theodore in the early 1990s. This model is a wonderful piece of model engineering. Since everything is hidden behind the skirt, anything was possible.

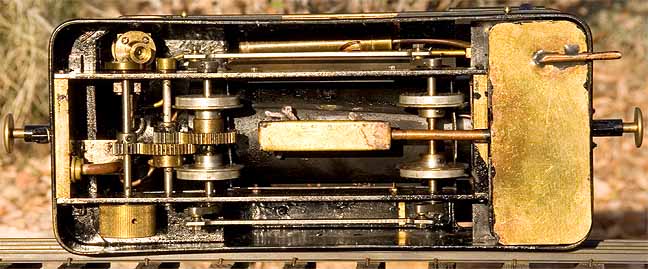

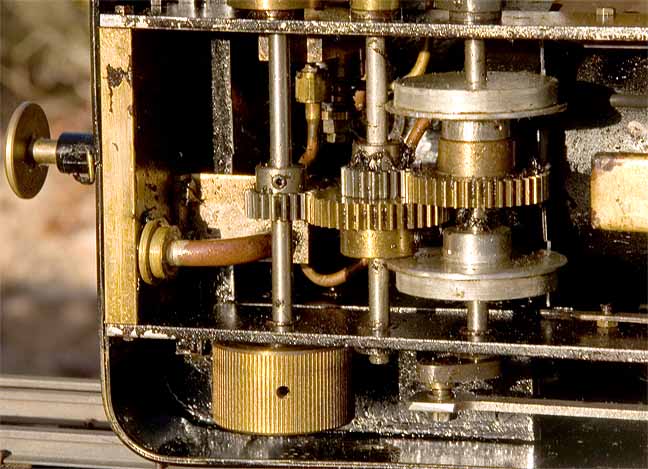

First of all, the model is an 0-4-0, not an 0-4-2 like the prototype. It is powered by one, double-acting oscillating cylinder, mounted vertically, outside the frames, at the front end. The cylinder is robustly constructed and includes an unusual (for an oscillator) crosshead guide to support the crosshead and minimize wear. It is geared via a double reduction to the leading axle. The brass gears are substantial. On the other end of the drive shaft is a knurled flywheel that can be accessed by a finger under the skirt to help set the engine in motion. The two axles are connected via traditional side rods. A displacement lubricator sits between the frames at the front end.

There's a large meths tank under the cab. The boiler is a simple pot, fired by a two-wick burner underneath. The fire is protected by a Wheldon-type heat shield. The top of the burner tube is only about 1/2" from the bottom of the boiler, so the wicks are splayed out. On the left side of the boiler is a whistle, sitting near the fire shield, which keeps it hot and avoids condensate problems common to whistles.

In the cab is the whistle valve, a throttle, and a pressure gauge. Access is tricky, due to confined quarters.

To service the engine, the outer shell must be removed. This is done in a matter of seconds via the buffers. They are sprung "backwards," as it were. Their inner ends form pins that engage the engine's frames. If you pull on the buffers, the entire body is released and can be lifted off -- very clever.

This engine was originally owned by Harvey Watkins, the well-known British 16mm modeler. Of the engine, he says, "I bought the tram, part completed, from Tony Sant [Finescale Engineering], so that I could fiinish it in the style it was delivererd to the GVT, before any modifications. I added the single-lever sandbox, the speed-quadrant at the smokebox, rodding and pipework along the upperworks, and the condensation pipes and tank vents. Some of the components, like condensation pipes came from Tony, as they were intended for the standard production model. Then I finished it off with the usual array of cans, jacks, bucket, etc. I worked to the drawing in John Milner's book but, in effect, did very little, as Tony's work was so well controlled. Geoff Munday of Lightlines did the lining out."

The finished engine looks just right.

The run

Run day was cool and clear, with the temperature in the 50s. I'd not run this engine in a very long time, so gave it a good visual going over before getting it ready. The first thing I noticed was that the lubricator drain line, which drains through the front frame member, was missing its plug. We'd not get far with that gone. A quick trip to the lathe produced a new one.

Once that was remedied, everything else looked okay. The gears were dirty, though, so I cleaned them up. I prepared the engine in the usual manner. When all was ready, I lit it up. Steam came up fairly quickly, and so did the whistle. The valve was stuck open. I managed to unstick it for the most part, but it still leaked. Once steam was up to around 40 pounds, I opened the throttle and turned the flywheel. After a reasonable amount of sputtering and spitting, the cylinder cleared and it was off -- for a little. Pressure quickly dropped. and the engine stopped. The performance was repeated and it became obvious that was the best it could do.

I suspected the problem to be wick trouble, perhaps combined with the leaky whistle valve. I dropped the fire and pulled out the burner. After some fiddling and adjusting of the wicks I put it back together and gave it another go. Performance was better this time, but still not up to snuff. The engine would make it around the loop once before running out of puff. I think the whistle valve is releasing more steam than is immediately apparent. Evening was coming on and a cold front was moving in, so the run was terminated and the locomotive was retired to the shop, where further investigation will be under way.

|

|

|

| Builder | Finescale Engineering -- detailed by Harvey Watkins |

| Date built | Circa 1991 |

| Gauge | 32 mm (regaugeable) |

| Scale | 16mm |

| Boiler | Pot |

| Fittings | Safety valve, pressure gauge, throttle, whistle |

| Fuel | Alcohol |

| Blow-off pressure | 45 psi |

| Cylinders | One, double-acting oscillator |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 5 lb. 8 oz. |

| Dimensions | Length, 9-3/4"; width, 4-1/4"; height, 6-1/4" |

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2008

.