Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

April 2009

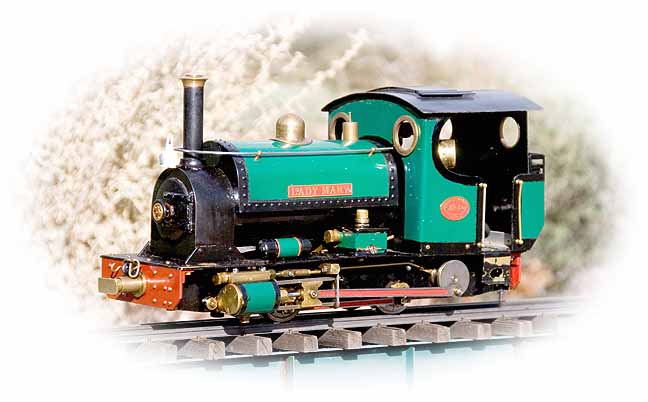

John Singer's Lady Mary

by Marc Horovitz

John Singer is a little-known British builder. He was a member of the East Anglia 16mm Group. Although his work is to a relatively high standard, his output appears to have been minimal, with perhaps half a dozen live-steam locomotives to his credit. He evidently gave up modeling in 1997, selling his equipment at that time. This is the last 16mm-scale locomotive that he built. (Thanks to Don Beach for this information.)

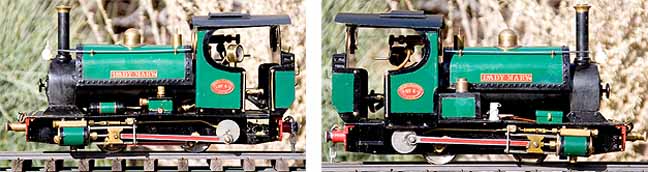

Lady Mary has a conventional, single-flue boiler, fired by butane gas. The gas tank is on the right-hand footplate, half in and half out of the cab. Boiler fittings include a safety valve, throttle, an exhaust regulator, and a pressure gauge. There is evidence that the engine may at one time have been radio controlled, probably throttle only. The dummy saddle tank can be lifted off for access to the safety valve / filler.

The cylinders are nicely made, with D-valves and functional crossheads and crosshead guides. There seems to be a certain amount of John Turner influence in the engine, as several of the details incorporated here were standard on John Turner's engines. These include the banjo fittings used to bring steam into the cylinders, the exhaust regulator on the smokebox front, and the box-type lubricator sitting on the left-hand footplate. The cab throttle is accessed through the right-hand cab window. It's a little awkward, but this throttle can be treated more or less as an on-and-off control, with fine control being provided by the exhaust regulator.

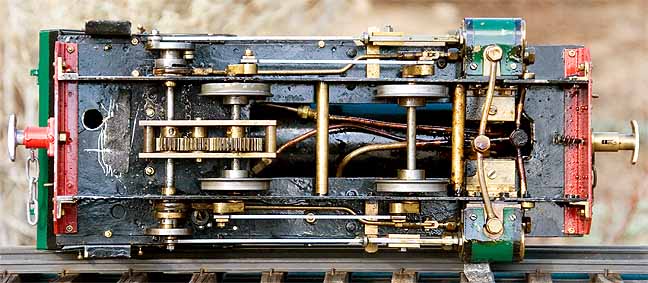

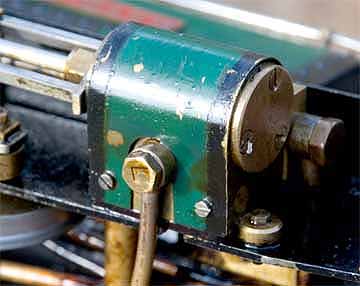

This engine's most unusual feature, however, it its drive. It is actually gear driven. The side rods power a jackshaft set behind and a little above the rear drivers. This jackshaft also carries the slip-eccentrics that actuate the valves. Between the frames is a gearbox that carries three robust spur gears. The jackshaft is geared to the rear axle via a 2:1 reduction, with an idler gear to keep the jackshaft and powered axle rotating in the same direction. The two axles are connected with conventional side rods.

The run

When I first examined the engine it quickly became apparent that it was a no-go. I discovered that one eccentric was stuck in mid position. The other one seemed fine. I disassembled one side of the jackshaft assembly and gave all of the parts a good cleaning. Upon reassembly, all was well.

I prepared the engine for its first run on my railway. The weather was cool but calm, with temperatures in the 40s. I lit the fire under the boiler, behind the smokebox. It snapped back into the flue instantly. Pressure came up well. When operating pressure was reached, I closed the exhaust throttle on the smokebox and opened the cab throttle wide. Then I slowly opened the exhaust throttle.

After the usual initial sputtering, the engine moved off, easily pulling the three coaches that came with it (built by Austin Major). I noticed a few minor steam leaks, suggesting that piston and valve glands should be repacked. Despite this, the engine ran smoothly and well.

It's unusual rod-and-gearing arrangement makes this a fascinating engine to watch. The gears, coupled with the exhaust throttle, make this an exceptionally controllable locomotive. Slow-speed running is easy and impressive.

In all, this is a wonderful little engine. I look forward to repacking the glands and having another go.

Here's a movie of the engine in action. If it doesn't work, click here to go to YouTube.

|

|

|

| Builder | John Singer, UK |

| Date built | 1986 |

| Gauge | 45 mm (regaugeable) |

| Scale | 16mm |

| Boiler | Single flue |

| Fittings | Safety valve, pressure gauge, throttle, exhaust regulator |

| Fuel | Butane |

| Blow-off pressure | 45 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Weight | 6 lb., 8 oz. |

| Dimensions | Length, 11-1/8"; width, 4-1/2"; height, 6-1/4" |

Below: A dummy coal bunker adorns the rear of the locomotive.

Right: The gearbox. The idler gear (the one in the middle) keeps the direction of rotation of the two outer gears the same. The slip-eccentric mechanisms can be seen outside the frames.

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2009

.