Back to Sidestreet Bannerworks

March 2001

Dutch Tram Engine

by Marc Horovitz

Tram engines were used throughout Europe and other parts of the world for duty on street railways and for light industrial and rural passenger service. They were also fairly common in the States, where they were called steam dummies. They often had completely enclosed bodies so that the flailing side rods wouldn't scare the horses, with whom the trams had to share the streets. At least this is what I have always read. How much truth there is to it, I don't know. In any event, the engines had concealing side skirts,

This engine is not a model of any specific prototype but generally follows the pattern of Dutch tram engines from around the turn of the century. These came in all sizes, and this model represents a middling large one.

The engine

When I set about building this model I had several parameters in mind. I wanted an engine that was fairly easy (and quick) to build; one that would be simple to operate; and one that would have a reasonably long duration. I wanted a locomotive that would be a slow, sedate runner, but that would have enough power to pull a reasonable train up moderate hills. Reversing wouldn't be necessary, as the engine was intended for continuous running while I laid back, did something else, had company over, or whatever. As far as operation was concerned, I wanted it to be a no-brainer, something I could be comfortable setting loose and ignoring for a half hour if I wanted to. The finished model, I'm pleased to say, satisfies all of these requirements.

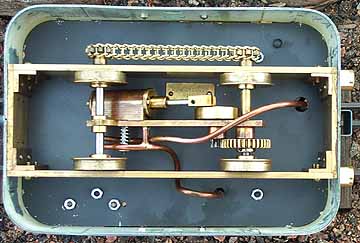

The frames are built up of 1/8" x 1" brass bar stock. The cylinder was salvaged from a dead Ruby, then converted into an oscillator, which some might consider going in the wrong direction. The finished steam motor was mounted between the axles. In fact, the axles supply its only support. It is tied into the front axle via the gearbox and it sort of floats about the rear axle, held in place by a rotating retainer. The front axle is driven through a 4:1 reduction gear while the rear takes its power from a ladder chain and homemade sprockets.

The boiler was silver-soldered up of copper tubing; the firebox is made of sheet steel. The burner is from Roundhouse and the displacement lubricator taken from the same Ruby that supplied the cylinder. The safety valve is from Mamod, blowing off at around 10 psi.

I made a little door in the side of the firebox so I could light and observe the flame. The gas tank is homemade, made of a flattened piece of copper pipe and reinforced with a couple cross stays. It was hydraulically tested to 100 psi. The filler valve and gas regulator were also donations from Ruby.

The body work is all sheet steel. The overlay strips were soldered on, a doorway was cut out of either side, and handrails were applied. Dummy lamps were made of brass, as per the drawing below. They look like plastic, but they are polished brass, lacquered. The unit was painted with Badger acrylic paint, which has held up pretty well, but not quite as well as I'd hoped.

Performance

The 1st of March was fairly moderate—cloudy, with temps in the 40s. The engine was oiled all round, as usual, and the lubricator topped up with steam oil. The boiler was filled about two thirds full and the gas tank charged. The fire was lit through the fire door and steam was up in about seven minutes. One nice thing about an externally fired boiler is that it is quiet, whether fired by gas or meths.

Once steam was up, I open the throttle. This engine is sometimes a little hard to start. You have to bear down on it a bit while pushing it, to get the cylinder to turn over against the reverse force of the gears. However, today it started up happily and trotted around my 150' loop for the next half hour unattended. The roof is always a mess of oil and water at the end of the run, but, being mostly smooth, is easy to wipe down.

| Specifications | |

| Builder | Marc Horovitz |

| Date built | January, 2000 |

| Gauge | 45mm (gauge 1) |

| Scale | 1:20 |

| Boiler | Pot boiler, externally gas fired |

| Fittings | Safety valve, throttle |

| Fuel | Butane gas |

| Blow-off pressure | 10 psi |

| Cylinders | One, double-acting oscillator |

| Reversing gear | None |

| Dimensions | Length over body, 7"; width, 4.75"; height, 6.25" |

Above: The roof is easily removed by unscrewing the two knurled knobs on top. The exhaust pipe can be seen inside the short stack.

Left: The engine with the top off. The steel firebox is lined with 1/8" Fiberfrax ceramic insulation. The throttle sticks out the front, above the boiler, for easy access.

Below: The crude builder's plate, riveted to the underside of the floor, was made with 1/16" letter and number stamps.

Right: The flame can just be made out through the firebox door.

Back to Sidestreet Bannerworks

This page and its contents Copyright

Sidestreet Bannerworks, 2001