Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

June 2009

Archangel's "Brick"

by Marc Horovitz

Archangel Models' locomotives have achieved cult-like status over the four decades or so since they were first introduced. (You can read a brief history of the company in our October 2000 "Locomotive of the Month.") For some people (including me), it is Archangel's early engines that have the most mystique about them. They were simple in the extreme, often almost caricatures of their prototypes, but embodied a certain innocent charm. But more importantly, they were well made, reliable, powerful, and (usually) easily controllable.

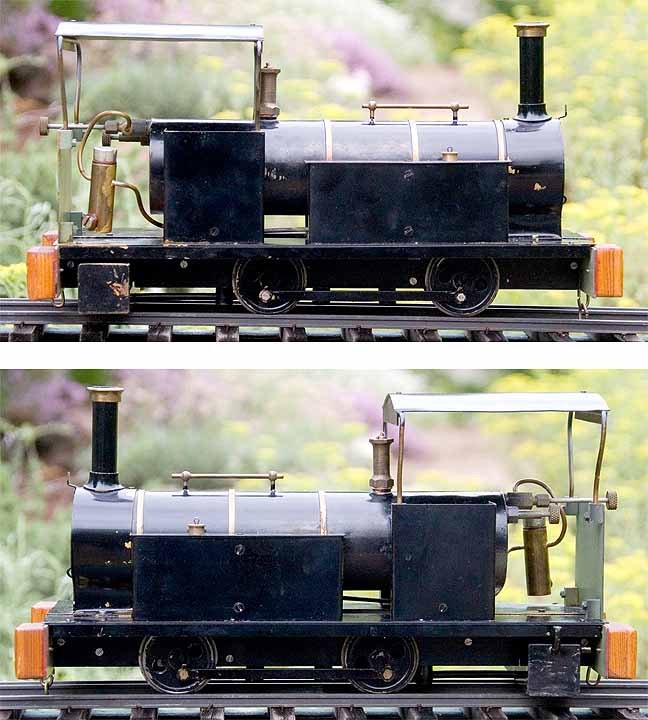

"Brick" is one of the company's earliest offerings, and it was made, in a variety of variations, for many years, starting in 1971 -- not that many years after Stewart Browne, Archangel's founder, started producing engines. According to Peter Dobson, in his book 16mm Scale Live Steam Model Locomotives, Archangel's "Brick" was based on a locomotive built in 1880 by Bagnall for the Beckenham & Penge Brickworks Ltd. (hence the engine's name). Interestingly, the "Brick" featured in Peter Dobson's book is different in many cosmetic respects from the one featured here.

"Brick" was the first simply constructed, simple to operate, low cost, narrow gauge, live-steam locomotive on the market. Thanks to Stewart Browne (for making the engines), and Jack Wheldon and Dave Rowlands (for writing about them in the British model press), "Brick" became an entry point into a new branch of an old, established hobby for many new live-steam enthusiasts.

The engine featured in this article was produced in 1977. It is meths fired, with a pot boiler and a three-wick burner. The fuel tank, which is under the cab, is fitted with a filler tube and an overflow tube.

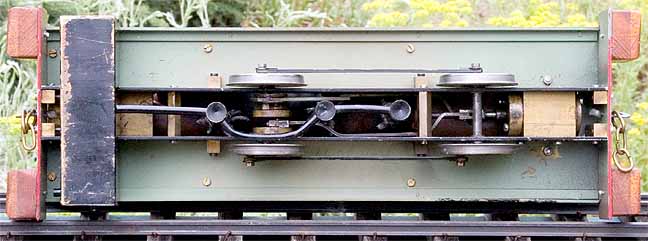

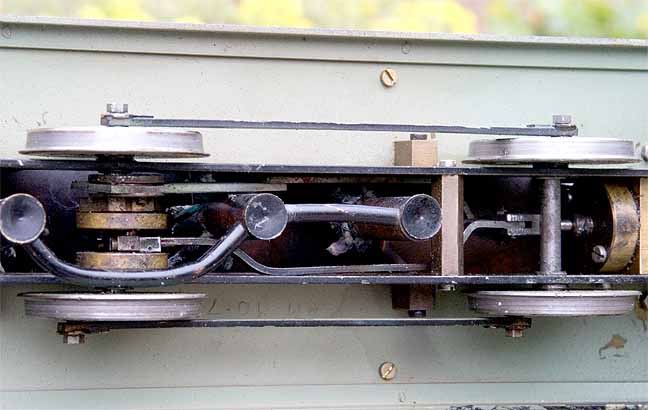

Boiler fittings include a safety valve, a throttle, and a blowdown valve. A large displacement lubricator is actually suspended from the steam line on the right side of the cab. The engine has just one, double acting, D-valve cylinder between the frames, controlled by a slip eccentric. Things are crowded between the frames, with all the motion work, the axles, and the burner trying to occupy the same space. The main rod is bent to avoid the burner, while the wick-feed tube is bent to avoid the crank axle. But it all works.

Body work is simple sheet metal. The cab roof, which is removable, is supported by four curly posts. These are (strangely) made of tubing, instead of solid rod, and are easily susceptible to inadvertent bending.

This engine was an eBay purchase. Sadly, it was inadequately packed and arrived damaged. Repairs were made as well as could be expected, but there are still some residual cosmetic flaws, particularly in the area of the dummy smokebox (lightweight sheet metal). The damage was repaired pretty well, but the paint suffered.

The run

Run day was ideal, an overcast afternoon with the temperature in the low 50s. I prepared the engine and lit it up. In due course pressure came up and the safety valve lifted (the safety's stem was broken off in shipping, bu it still works okay). I gave it a push and it was away.

I found on earlier runs with this engine that, unlike many Archangel locomotives, this is a fast engine. It is nearly impossible to slow it down and have it stay that way. In an attempt to retard it a little, I tied on a train of 20 axles. The engine walked away with it -- no, it ran away with it. There was just no slowing it down, so I was forced to let it run fast, which it did for lap after lap, with the safety valve occasionally blowing off. Despite the speed, it was a great run.

I'd like to do a little comparative work between this engine and other Archangel locos to try to discover why it is not as controllable as the others. Perhaps I can modify it to be more docile.

Here's a movie of the engine in action. If it doesn't work, click here to go to YouTube.

|

|

|

| Builder | Archangel Models, UK |

| Date built | 1977 |

| Gauge | 32 mm |

| Scale | 16mm |

| Boiler | Pot |

| Fittings | Safety valve, throttle, blowdown |

| Fuel | Alcohol |

| Blow-off pressure | 45 psi |

| Cylinders | One, double acting, D-valve |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Weight | 4 lb., 8 oz. |

| Dimensions | Length, 10-3/4"; width, 4"; height, 5-7/8" |

Below: However, when you get closer, the complexities involved in cramming a lot of machinery into a small space become more evident. Note how both the main rod and the meths feed pipe are shaped to fit the available space.

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2009

.