Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

November 2009

Prescott Engineering's Robin

by Marc Horovitz

Prescott Engineering was founded in 1994 by John Prescott. Robin is an attractive model of a typical British industrial locomotive. While it does not represent any particular prototype, it has many of the characteristics of the small engines that a variety of manufacturers supplied to commercial firms around the world.

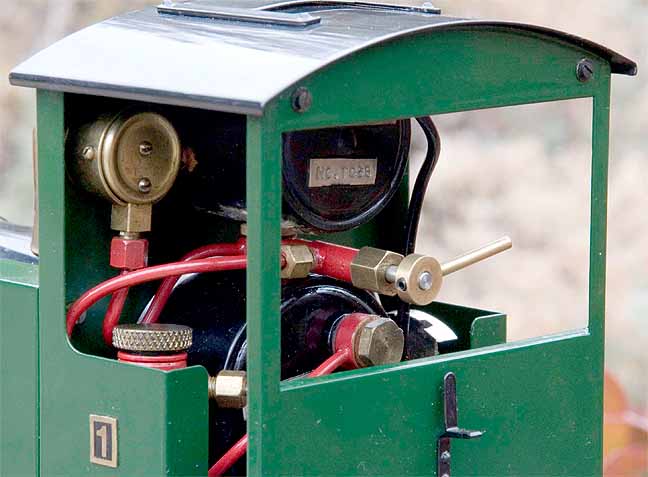

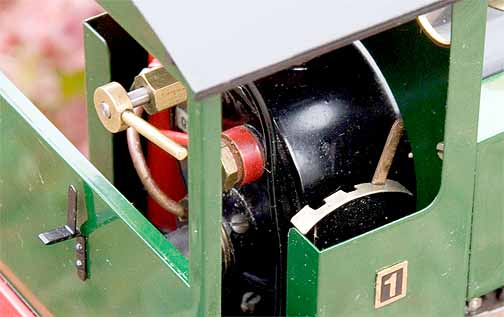

A short but large-diameter boiler gives the engine a pleasing “chubby” look. The boiler has a single flue and is fired by butane. Gas is carried in a tank under the cab roof. To fill it, you slide back a hatch on the roof to reveal the filler valve – a nice touch. The gas-control lever protrudes from the front wall of the cab, just beneath the roof. While this sounds a little clunky and toylike, the valve is small, nicely made, and in keeping with the other fittings on the engine. It doesn't actually look out of place.

Boiler fittings include a safety valve under the lift-off brass steam dome, a throttle, a pressure gauge that you must read through a front cab window, and an ENOTS fitting for filling the boiler under pressure. A displacement lubricator sits next to the left side of the boiler. You need an allen wrench to open the drain plug.

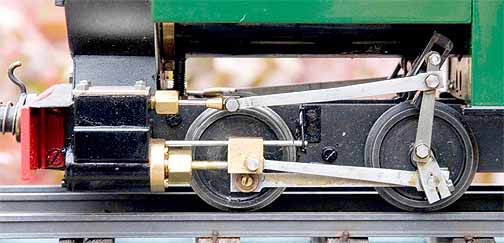

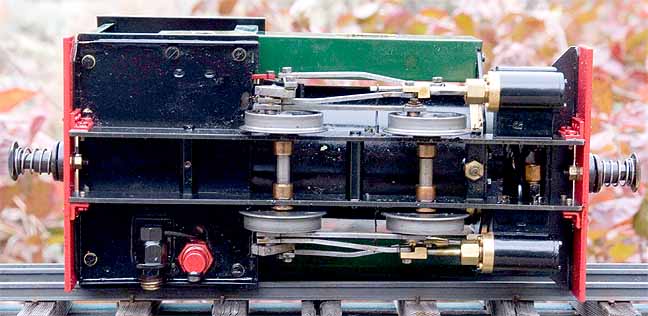

Side tanks are dummies, as are the filler hatches atop them. Bodywork, according to the manufacturer's literature, is made primarily of nickel silver, not the customary brass or steel. Sheet-metal work is neat and cleanly done, with no rivet or other added detail. This is a plain, workmanlike locomotive. The chassis is unsprung and all axles are bushed in the frames.

The tiny cylinders have outside valves controlled by Hackworth valve gear. This is operated from the cab by a lever that locks into forward, neutral, or reverse positions. End beams are fitted with sprung (outside springs!) center buffers. Lamp irons adorn the smokebox and back sheet.

The run

Once the engine had been prepared for operation, I opened the gas valve and placed a match near the stack. The fire caught at once. For a single flue, gas-fired boiler, this one is remarkably quiet in service.

This is a very lively locomotive and is a challenge to run light. It does much better with a train – preferably a heavy one. I tried it running light first. It has an odd habit of speeding up and slowing down as the safety valve lifts. I found it difficult to reduce the fire to the point that the safety wouldn't lift.

After some exercise chasing the engine around my track, I tied on a short train. Even this helped considerably. The engine settled down quietly to its work with no more histrionics. It could easily have dealt with a longer, heavier train.

Robin has charming proportions and is a delight to see working in the garden. With the ENOTS fitting, it can be kept in steam indefinitely, shutting the gas down long enough to refill it. It's a fun engine to run.

Here's a movie of the engine in action. If it doesn't work, click here to go to YouTube.

|

|

|

| Builder | Prescott Engineering – John Prescott (UK) |

| Date built | 1994 |

| Gauge | 0 gauge |

| Scale | 1:24 |

| Boiler | Single flue |

| Fittings | Safety valve, pressure gauge, throttle, ENOTS filler valve |

| Fuel | Butane |

| Blow-off pressure | 45 psi |

| Cylinders | Two, double acting, D-valve |

| Reversing gear | Hackworth |

| Lubricator | Displacement |

| Weight | 3 pounds, 12 ounces |

| Dimensions | Length over end beams, 7-3/16"; width, 3-3/4"; height, 5-3/4" |

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2009

.