Back to Sidestreet Bannerworks

April 2001

De Winton Quarry Locomotive

by Marc Horovitz

De Winton was a builder of industrial locomotives and quarry equipment in Great Britain, starting around 1868. The company’s engines were widely used in the Welsh quarries and some may even have been exported to the US. Though tiny, they were powerful. The prototype locomotive had a two-cylinder steam motor attached vertically to the boiler and geared to one axle. The engine was small enough to be easily managed by one man.

The engine

This is sort of a stand-off scale model, as the prototype had several distinctive features not included on the model. The most obvious, of course, is that the model runs on one, single-acting oscillator.

This little engine (one of the tiniest 16mm locomotives I know of) was designed by Jim Wild of England around 1979 or so. He built a few of them, then turned production over to Maurice Cross, who, as I understand it, was not so much a hobbyist as a contractor. This engine is from one of his batches. I don't know how many were made in total, but it couldn't have been very many.

The locomotive is neatly made, mostly of brass. The boiler has a single, vertical flue with one alcohol burner beneath it. It requires a suction fan to get it going, after which the exhaust from the cylinder takes over. In this respect, it's kind of a funny engine—it has the most primitive steam motor (an oscillator) driven by a fairly sophisticated boiler. The only fitting on the boiler itself is a low-pressure safety valve.

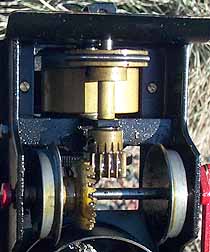

Speed (what little there is) and direction are controlled by a diminutive rotary valve mounted on the side of the port block. This is actuated by a prototypical-looking lever on a quadrant near the boiler. The cylinder powers a shaft that carries a flywheel and pulley. Around the pulley is a spring belt that drives a second shaft below the first. At the other end of this shaft is a large-ish pinion that drives a crown gear on the axle. The other axle is driven conventionally via side rods.

The locomotive is painted black with rods, reversing lever, and other bits picked out in red. Altogether it’s quite attractive.

Performance

When I first got this engine, 20+ years ago, it was not a good performer. At the time, I didn't realize that the suction fan was required to get steam up. I figured that since it was a vertical boiler, natural draft would do the job. But even once I started using a fan, the engine still ran poorly. Steam pressure came up OK, but when it was time to go, the engine had no power at all, not even enough to keep the fire going. After some frustrating detective work, the problem came to light. There was grit in the exhaust line. This had the dual effect of choking the engine and preventing sufficient exhaust blast to maintain the fire. Once this problem was solved, the locomotive was transformed.

So, with the temperature in the upper 60s and a gale-force wind howling, I set out to run the engine. The bottom of the boiler is fairly exposed, so I anticipated some difficulty with the wind. With the steaming-up ritual complete, I dropped the fan into the stack and lit the fire. On this tiny engine, steam was up in less than three minutes. A flick or two of the flywheel, and off it went.

When traveling flat out, this engine runs slowly. Top speed is probably a prototypical 8-10 miles per hour. It won't keep up with even a leisurely walk. However, it is surprisingly loud. The exhaust beat was audible even when the engine was at the far end of the line, 50 or 60 feet away, and with the wind blowing in my ears to boot. The breeze proved to be no problem at all, and I got a respectable and satisfying 15 or so minutes run out of the little boiler, with two or three stops for refueling. This is a fun engine to run, but it requires that you learn it. Too little pressure in the boiler and steam cannot be maintained. But when everything is right, it runs like a top and looks great in front of a string of slate wagons.

Read Jim Wild's additional comments on this engine.

| Specifications | |

| Builder | Maurice Cross to Jim Wild design |

| Date built | circa 1979-1980 |

| Gauge | 32mm (gauge 0) |

| Scale | 16mm = 1'-0" |

| Boiler | Single-flue vertical, internally fired |

| Fittings | Safety valve |

| Fuel | Alcohol |

| Blow-off pressure | 25 psi |

| Cylinders | One, single-acting oscillator |

| Reversing gear | Rotary valve |

| Lubricator | None |

| Other features | Double reduction gearing via spring drive belt, flywheel, and crown-and-pinion |

| Dimensions | Length over body, 6-1/2"; width, 2-1/8"; height, 5-1/4" |

Above right: The steam line runs from the boiler (via a banjo fitting) to the reversing valve, which is controlled by the red lever near the boiler. Speed control is nearly nil, since top speed is so slow to begin with. The exhaust line goes to the stack, where a cross hole in it serves as a jet to keep the fire going.

Left: A single wick fires the boiler. Asbestos strands are splayed out beneath the center flue. The fuel tank is below the footplate at the brake-staff end of the engine.

Right: Firing up with the aid of an Aster suction fan. Steam is usually raised in under three minutes.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2001