Back to Sidestreet Bannerworks

September 2001

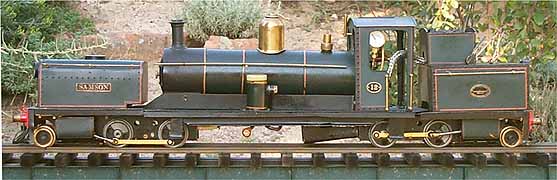

Mac Muckley’s Samson 2-4-0+0-4-2

by Marc Horovitz

The Beyer-Garratt locomotive is one of the more unusual articulated engines. It was widely used in many parts of the world (not including North America, alas). It has no detachable tender, but is articulated in two places. The first section incorporates a steam power truck, or bogie. Atop this sits a water tank. The third section is a similar bogie, though reversed in wheel arrangement. Atop this sits another water tank and fuel bunker. Slung between these two bogies, and pivoted to them, is the boiler. The cylinders are usually (but not always) situated at the outside ends of the bogies.

There were many advantages to this type of engine. Since there were no obstructions (frames, wheels, etc.) under the boiler, the boiler could be designed for maximum efficiency without concern for bumping into anything beneath it. These locomotives were exceeding flexible, able to negotiate relatively rough track and very tight curves, despite being long and heavy. Also, as the engine went around a curve, its center of gravity moved toward the center of the curve (because of the placement of the boiler), making it uncommonly stable.

The Beyer-Garratt engine was the brainchild of Herman William Garratt, a British locomotive inspector, engineer, and inventor. He was granted a patent for it in 1907. Within months he had convinced Beyer, Peacock, a well-established British locomotive-building firm, of the merits of his design. The first Beyer-Garratt locomotives, a pair of tiny, 2'-gauge 0-4-0+0-4-0s, were delivered to the Tasmanian Government in 1909. From there, the design took off and many locomotives were built to this plan over the years in a variety of sizes and gauges. They were used in Africa, Australia, South America, India, Great Britain, and other places.

The model

I purchased this engine second-hand from the builder at a show in Britain in 1985. It is a freelance design, but incorporates all of the usual Garratt characteristics. It is built on two Mamod 0-4-0 chasses. The oscillating cylinders are hidden behind cylinder covers. A Mamod engine is reversed by a rotary valve that exchanges admission and exhaust steam. This is located between the frames, at the front. These valves were retained on this engine and linkages were added at each end of the locomotive so that the valves, which are pretty well hidden, could be accessed from one side of the engine. However, each engine must be manually reversed separately. If you're not careful, one engine will be traveling forward while the other wants to go backward.

This locomotive has a variety of unusual goodies on it. Neither bogie exhausts up the stack. Exhaust steam from both is expelled into condensing pans. One is hidden under the front power bogie and the other is disguised as the firebox, for the benefit of the rear bogie. On cool days, lots of steam pours from beneath the engine—an interesting effect.

The boiler is a traditional, single flue, gas-fired unit, with a poker-style burner. Gas is stored in a tank above the rear bogie. The boiler is fitted with the usual safety valve, plus a pressure gauge and water glass. The throttle is actually under the steam dome, and is actuated by a small lever on it.

This engine is fitted with a vacuum tap. This is a somewhat unusual device, but a useful one. When the fire is dropped, residual steam in the boiler condenses back into water, creating a vacuum in the boiler. If you have a valve in the backhead placed at the maximum water level, and a hose to a water supply, this vacuum can be used to draw water into the boiler. On this Garratt, there is such a valve, and it is connected to a pipe that communicates with the front (functional) water tank. This isn't as useful as being able to fill the loco while it's under steam, but it saves taking off the safety valve to fill the boiler, and it's fun to watch.

Performance

The first run of the engine was not good. After going through the initial preparation ritual, the fire was lit. The engine hadn't been run in over 10 years, but it lit right off (which is always gratifying).

Once, years ago, I had a problem with this engine. It had a partially clogged jet. This is one of the most exasperating problems a gas-fired engine can have. Enough gas was getting through to ignite the fire, but not enough to really do the job. Performance was sluggish at best, with frequent stops to raise steam. Once the problem was correctly diagnosed (after a lot of time was spent pursuing several incorrect diagnoses), the jet was simply blown out and replaced. The engine was transformed! What had previously been a reluctant and petulant participant now showed great enthusiasm, zeal, and cheerfulness.

So, I was heartened when the fire lit quickly after so long a hiatus. When steam had come up to about 20 pounds, I noticed a little water leak around the sight glass. As pressure climbed, this quickly became a geyser. Clearly, this engine was going nowhere. I shut off the fire and let the loco run a few yards on the residual steam in the boiler.

The next hour or so was spent removing the cab and tearing down the water glass. As suspected, an 0-ring had separated somewhere in the depths of time. While repairing it, I managed to fracture the glass. I found that I had no spare of that size. After a few well-chosen remarks, I figured the only way I was going to get a run out of this engine would be to plug the water glass fittings. A quick trip to the lathe produced a pair of suitable brass plugs. These were duly installed and the engine reignited.

This time it was trouble free. At 20 pounds I opened the throttle (after making sure the two engines were in agreement about the direction of travel), and we were off. The locomotive ran smoothly through the dual-gauge switches, and around the curves. It is easily controllable and will glide along at a sedate speed, even when running light. In short, it is a joy to run. Performance is identical in both directions. It's great to see the engine articulating its way through the curves. After 20 minutes or so, the engine ran out of gas, and so ended the run.

| Specifications | |

| Builder | Mac Muckley (Great Britain) |

| Date built | Circa 1982 |

| Gauge | 32mm (gauge 0) |

| Scale | 16mm |

| Boiler | Single flue |

| Fittings | Safety valve, throttle, pressure gauge, water glass, vacuum tap |

| Fuel | Butane |

| Blow-off pressure | 40 psi |

| Cylinders | Four, double acting oscillators |

| Reversing gear | Rotary valve |

| Lubricator | Displacement, on the footplate |

| Dimensions | Length over pilots, 22-7/8"; width, 4"; height over stack, 5-1/2" |

Right. Gas is stored in the rear tank, filled through the hole in the top deck. Flow is controlled with the lever protruding from the coal bunker.

Below right: Samson's front bogie. Oscillating cylinders are concealed behind shrouds.

Far right: The linkage from the little bell crank to the reversing valve can be seen here.

Right: The Garratt on a curve. The flexibility of the engine can be seen as it negotiates a switch. This is one of the prototype's great assets.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2001