Back to Sidestreet Bannerworks

April 2002

LBSC's Small Bass

by Marc Horovitz

LBSC were the initials of Britain's London, Brighton & South Coast Railway. LBSC was also the pseudonym of one of the most famous and idiosyncratic of all miniature-steam-locomotive designers. LBSC -- Curly, to his friends -- was born (most likely) in 1882 and christened Lillian Lawrence. Why he was given a girl's name is unclear, as are whatever reasons there might have been for him not changing it later.

Curly loved steam locomotives from the time he was a child and spent several years in the employ of the LBSC Railway, from which he later adopted his pen name. He began writing construction articles for the various British model-engineering magazines around the mid-1920s and continued through the middle 1960s. During this time, designs for well over 150 different locomotives, from gauge 0 up to 5" gauge, were published in a variety of different magazines. Some of these designs were later produced in book form (still available today).

It was LBSC's contention that any person with enough desire could build a working steam locomotive. Many of his designs were based on actual engines, though they were usually modified and often simplified for the home builder. All were robust in nature and good performers. His notes on various aspects of locomotive construction were compiled into a book called Shop, Shed, and Road, still considered to be a standard reference for the model engineer.

Curly Lawrence, through his entertaining and readable "words and music," introduced thousands of people to the joys of machine work and miniature steam locomotives. There are countless locomotives built to his plans still operating on tracks around the world. He passed away in 1967.

[Much material for the brief notes above came from Brain Hollingsworth's excellent book "LBSC": His Life and Locomotives, Croesor Junction Press, 1982.]

The engine

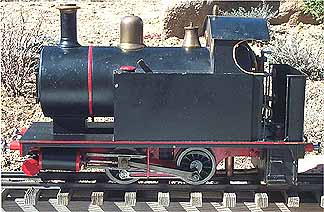

Small Bass is one of LBSC's lesser-known designs and almost the only one that could be construed as a narrow-gauge engine. It was published in English Mechanics magazine in 1930, evidently for both gauge 0 and 1. My example (builder unknown) is gauge 1, and is a truly unusual engine. It is to an indeterminate scale and is oddly proportioned. In 7/8" scale (or larger) it could almost be considered a model of a miniature engine.

The backplate is removable, revealing a well-supplied backhead. There is a regulator lever, a blower valve, a blowdown valve, and a water glass, all neatly laid out. A pressure gauge was evidently added at a later date and this, too, was neatly done. The engine sports working side tanks and there's a hand pump in the left one, with a balance pipe between the two to keep the water level even.

A good old Smithies boiler, with three water tubes in the fire space, supplies the steam. The outer boiler shell is a whopping 3" in diameter and the inner boiler is relatively large, too. The smokebox door is removable (though it is not hinged) and the exhaust and blower pipes can be seen inside. A displacement lubricator resides below the front deck and the engine must be turned on its side to fill it.

Traditional, fixed, D-valve cylinders power the engine. These have their valves inside the frames and are controlled by slip eccentrics. A copious fuel tank is slung beneath the footplate in the cab, feeding a three-wick burner in the firebox. This engine has an unusual and charming feature for a boiler of this type -- a firedoor in the backhead through which the fire can be lit. The burner can be dropped in a second by removing a retaining pin in the cab. All in all, the workmanship on this locomotive is to a pretty high, workmanlike standard.

When I first got this engine, some years ago, it needed some attention. The axles were originally sprung, but some of the springs were gone and others had been weakened to the point that the engine sloshed down the track at an odd angle. For the sake of expedience, I removed all the springs and blocked the axles in place with bits of brass tubing, essentially giving the engnine a rigid frame. I also had to replace some of the suspension pieces that had gotten lost or damaged.

The run

After lubing all round and filling the displacement lubricator with steam oil, I filled the side tanks with distilled water through the slot in the left one (the filler caps are dummies!) and tried to pump water into the boiler with the hand pump. However, the ball in the check valve was stuck and the pump wouldn't work. Instead, I removed the safety valve and filled the boiler to about half the glass. Then I inserted a suction fan into the stack and lit the fire through the fire hole in the backhead (fun), checking with a mirror underneath to make sure that all wicks were lit. While pressure was coming up, I wiped down the rails.

Steam came up in a few minutes. There was some weeping around the regulator shaft, probably due to dried out packing. At around 20 pounds I removed the fan and opened the blower valve just a little. I am particularly fond of internally fired engines with blowers. They sound alive even when sitting. Pressure continued to rise until the safety blew smartly at 50 pounds. I opened the regulator and the engine was off like a rocket. I had to run fast to catch it. This is a heavy piece of machinery. Its boiler and cylinders are more suited to a 3-1/2"-gauge engine. Running light, it was difficult to control, but I finally got it running sedately, with the regulator just cracked. A heavy train would have really enhanced its performance.

After fifteen minutes or so, I replenished the fuel and gave the hand pump another go. This time it worked, so I replaced the dwindling water. With the luxury of a pump, the locomotive could be kept in steam all day. Pressure was easily maintained with the blower off and the engine was a delight to run.

There is a lot of metal in this loco and it gets hot. However, it ran splendidly in both directions -- not bad for an engine that may have been built nearly three quarters of a century ago. Sort of makes one think about the engines we're building today -- where will they be in the year 2100?

It is great fun running an engine of this vintage. I think, here I am, replicating the actions of some unknown live steamer in the first half of the 20th century, seeing the same sights, hearing the same sounds, and smelling the same smells. Wonderful stuff!

|

|

|

| Designer | LBSC (Great Britain) |

| Builder | Unknown |

| Date built | Unknown (possibly around 1930) |

| Gauge | 45mm (gauge 1) |

| Scale | Indeterminate |

| Boiler | Smithies, with three water tubes |

| Fittings | Safety valve, regulator (throttle), blower, pressure gauge, water glass, blowdown, hand pump in lefthand tank feeding boiler through check valve |

| Fuel | Alcohol |

| Blow-off pressure | 50 psi |

| Cylinders | Two, double acting, with inside D-valves |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Dimensions | Length over buffers, 13"; width, 4-1/2"; height over stack, 6-1/2" |

Right: The usual plumbing (exhaust pipe and blower pipe) can just be seen inside the smokebox. The door, although not hinged, is held in place with the traditional dart and backbar.

Above right: Fifty pounds on the clock and the safety valve is lifting.

Right: The massiveness of this 0-4-0 becomes apparent when compared to a Roundhouse Katie.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2002