Back to Sidestreet Bannerworks

May 2002

Binnie-Mamod 2-6-0

by Marc Horovitz

When Mamod introduced its railway system in 1980, it was the first complete steam railway set offered to the public in decades. Its advent created quite a stir. The initial set included a small 0-4-0T industrial locomotive, a log car with plastic logs, a four-wheel gondola, a loop of odd, cast-metal track, and some instructions and accessories, all attractively packaged in a display box.

The heart of the system, of course, was the locomotive. Scaled nominally at 16mm = 1'0", it featured a pot boiler that powered a pair of double-acting oscillating cylinders. Reversing was accomplished by a rotary reversing valve that exchanged admission and exhaust steam, thus reversing the engine. This valve was positioned immediately behind the front buffer beam and was actuated by a small lever that stood up in front of the smokebox. The boiler was fired by vile-smelling and inefficient white pellets (often referred to by users as camel dung).

It didn't take modelers long to discover this new entry in the steam market. It had lots going for it. First, it was the cheapest thing around. Once the pellet burner was replaced by (usually) a proper alcohol burner, offered by several after-market manufacturers including Sidestreet Bannerworks, the engine was a reliable and surprisingly strong runner. But best of all, perhaps, was that it could be easily modified into a thousand different forms, using the engine's basic components. Mamod conversions started showing up on garden railways all over the world. Articles on "Mamodifications" appeared in a wide variety of different magazines and included everything from simple mechanical improvements to radical surgery that transformed the locomotive into something its designers never dreamed of. The locomotive discussed here is one of the latter.

The engine

I acquired this engine recently from a friend, Eric Lloyd. It was rebuilt by well-known British modeler Colin Binnie, who affixed his works plates to the cylinder covers. Colin made radical changes to the engine's design, but somehow managed to retain its spirit.

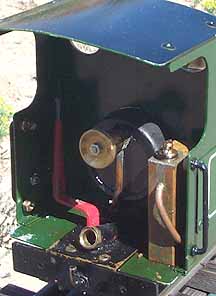

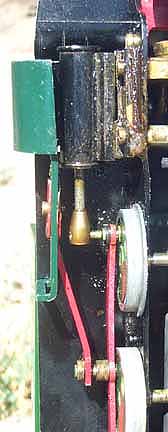

The boiler is all new, copper and silver soldered. The sight glass sported by the original boiler was lost. What was gained, however, was a higher-pressure boiler, a proper throttle valve, and a displacement lubricator in the cab with a drain below the footplate. A new gas burner was made and mounted beneath the pot boiler. A gas tank in the tender is connected to the burner by a large-diameter silicone tube.

A new chassis was made of steel and the Mamod wheelsets mounted in it in the same way they were mounted in the original. A third set was added in the middle, and these drivers had their flanges turned off. A leading truck was added, to which the coupler is attached. A cab-mounted lever system was devised, with a linkage forward to operate the reversing valve.

Mamod engines have oscillating cylinders, but this one appears to have fixed cylinders and crossheads. In fact, the fixed cylinders, crossheads, and main rods to the second axle are dummies. The engine retains its original oscillating cylinders, but these have been painted black and are hidden behind the new shrouds that represent fixed cylinders. The oscillators drive the leading axle, but this mechanism is (partly) hidden by the dummy crosshead and main rod on each side. When in operation, this dodge is scarcely noticeable and the engine looks like it has fixed cylinders.

The body work on the locomotive is pure Mamod. Even though the boiler has been stretched, the original side tanks (replete with Mamod graphics) were retained, as was the cab front and roof. A small, four-wheel tender was scratchbuilt by Colin, which obviated the need for the cab back.

The tender carries a gas tank and a dummy coal load. It is all metal in construction, but has plastic wheels. Loco and tender are fitted with traditional center-buffer couplers. All of the modifications on the engine are neatly done without being fussy.

Performance

I don't know when this engine was last run at Eric Lloyd's. I suspect it had been quite some time. The O-ring on the regulator knob that protected fingers from heat had broken away. Anyway, after repairing a stuck dummy crosshead, I went through the usual routine of oiling all moving parts and filling the lubricator, gas tank, and boiler with their respective fluids. With the engine on the track, I cracked the gas valve and inserted a lit match between the frames and the rails. The fire caught instantly. When burning in the open air, a gas fire is very quiet -- only a faint hiss could be heard.

After a suitable time, and when the safety valve started bubbling, I pushed the reversing lever forward and opened the throttle. The engine immediately started off -- in reverse. With the lever pulled all the way back, it set off in the forward direction.

The locomotive retains much of its original Mamod spunk, although the additional drivers and added weight make it behave like the larger engine that it is. It runs better in reverse than forward. There seems to be a steam leak when in forward gear that needs sorting out. It does run forward, but with an odd hissing chirp most unbecoming a steam locomotive. Overall, though, throughout its 20-minute run it was a smooth and controllable locomotive that would look great heading up a train of small freight or passenger stock.

|

|

|

| Builder | Colin Binnie / Mamod |

| Date built | Unknown (post 1980) |

| Gauge | 32mm (gauge 0) |

| Scale | 16mm |

| Boiler | Pot (built by C. Binnie) |

| Fittings | Safety valve, regulator (throttle) |

| Fuel | Butane |

| Blow-off pressure | 40 psi (est.) |

| Cylinders | Two, double acting oscillators |

| Reversing gear | Rotary reversing valve operated from the cab |

| Lubricator | Displacement |

| Dimensions | Length over end beams (loco and tender), 18"; width, 4"; height, 5-1/2" |

Above: A fat silicon tube feeds the burner from the tank in the tender.

Right: A gas burner under the rear portion of the boiler is evident in the picture. Next to the drivers on the right side can be seen the reach rod from the reversing lever in the cab to the valve between the cylinders.

Above: A coal load graces the top of the tender, while the gas tank sits in front of it.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2002