Back to Sidestreet Bannerworks

September 2002

Aster's JNR 2-6-0

by Marc Horovitz

When people speak of the Aster Mogul, they are generally referring to the C&S 2-6-0. However, there was another, earlier Mogul produced by this prolific Japanese company—the JNR Mogul. The American Locomotive Company (ALCO) built around 60 of these attractive engines for the Kyushu Railway Company's 3'6" line, between 1899 and 1907. Examples of this engine were in service for fifty years, into the period when the railways were nationalized into the Japanese National Railway (JNR). These successful locomotives were used in both freight and passenger service. (Information from Aster’s catalog.)

The model

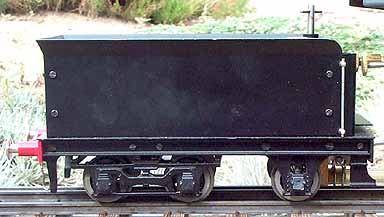

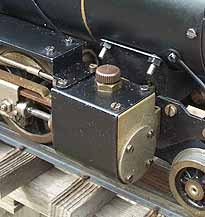

Aster’s model of this prototype is interesting for a variety of reasons. It was issued more or less simultaneously with the British-style "Schools" class 4-4-0. Together, these were the first live-steam model locomotives the company ever produced. Mechanically they are quite similar. They shared the same size cylinders and Smithies-type boilers. Each has a blower valve, a throttle, and a check valve for filling the boiler from an external pump. The "Schools" is reversed via slip return cranks while the Mogul is reversed by a slip eccentric. Both engines carry alcohol in a tank in the tender that is fed to the burner via a chicken-feed system.

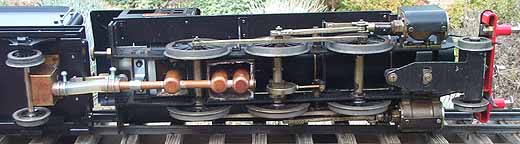

The engines differ, of course, in nationality, wheel arrangement, scale, and general appearance. However, there is a more significant difference. The JNR Mogul, as originally presented, had but one working cylinder, on the left side. The right-hand dummy cylinder actually housed the displacement lubricator.

Some years after it was initially offered, Aster reissued the engine in an "Americanized" version. The most significant differences between this and the original were that the tender now had four axles (two trucks) instead of three (one truck and one fixed, leading axle) and the engine was also equipped with two working cylinders. I believe a retro-fit kit was also available for those who already had a single-cylinder Mogul. This made an ideal basis for kitbashing the engine into something truly American. Pete Olson, of West Lawn Locomotive Works in Wisconson, for a time offered these locomotives with a new, larger cab, stack, and other additions as a 1:24 scale, narrow-gauge engine.

The engine is spartan in its appearance and amenities. I particularly like it because it is an example of Aster's earliest work in this field and it serves as a sort of corner stone from which future accomplishment can be measured. These models still show up from time to time on the secondhand market, often for quite reasonable money, especially for the one-cylinder version.

The run

Today was another really hot day in Denver, well into the 90s. People who run live steam in the intense heat must be nuts. That aside, hot weather can significantly alter an engine's performance. It can turn a normally lively engine into a rocket.

After oiling all around, I fitted the suction fan into the stack to draw the fire while steam was being raised, opened the alcohol valve in the tender, and lit the asbestos wicks. Steam came up smartly and I was soon able to open the blower and dispense with the fan. As pressure rose, I noticed that the clack valve in the cab was weeping a little, but this would not be a problem. Once pressure had come up sufficiently, I opened the throttle. The engine jumped ahead -- no messing around with clearing condensate today! Performance was nothing short of spectacular, with the two exhaust beats per revolution clearly audible.

All of the control of this engine takes place in about two or three degrees of throttle rotation. After that, it's just flat out. The engine really needs a train to calm it down, especially on a day like this, but I was running it light. About 15 minutes into the run, a problem developed. The sump in the tender started leaking alcohol onto the track, which promptly ignited when the engine stopped and which burned under the tender when it was in motion, heating the tender to the point where I couldn't touch it. Pressure rose in the boiler as well, and the engine was soon out of control, running faster than I could. I'm certain that a speed record was set on the Ogden Botanical Railway today. After traveling three-quarters of the way around the loop at an impossible rate, the locomotive finally took flight. Serendipitously, a friend, Rich Maul, was on the spot and was able to sort of catch it and prevent it from taking a high-speed nose dive into the gravel, two feet below track level. We quickly replaced the engine on the rails, turned off the alcohol valve, and let it quietly run off the little fuel that hadn't already leaked out of the sump. All in all, it was an eventful and interesting run -- one I hope never to repeat.

|

|

|

| Builder | Aster Hobby Company (Japan) |

| Date built | 1975 |

| Gauge | 45mm (gauge 1) |

| Scale | 1:30 |

| Boiler | Smithies |

| Fittings | Safety valve, throttle valve, blower valve, check valve |

| Fuel | Alcohol, chicken-feed system in tender |

| Blow-off pressure | 45 psi |

| Cylinders | One, double-acting slide valve on left side |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Dimensions | Length over buffers (including tender), 20-13/16"; width, 3-11/16"; height, 5" |

Right: Blower on the right, throttle on the left, and a clack valve in between.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2002