Back to Sidestreet Bannerworks

July 2000

Aster's SNCF 232TC 4-6-4T

by Marc Horovitz

This locomotive was one of a class of engines built from 1912 through 1923. Similar locomotives were built for both the Prussian Railways and the Alsace-Loraine System, when Alsace was still part of the German Empire. They were popular locomotives, easier to operate and mechanically simpler than their predecessors, and they remained in use through the late 1960s.

(Information courtesy Aster Hobby, Inc.)

The model

The model was produced by Aster of Japan in 1978, both in the French and German versions, which were mechanically identical. (The French version is pictured here.) The models featured full, working Walschaerts valve gear, a Smithies boiler, and alcohol firing. The locomotive was offered in both kit and built-up forms, as are most Aster locomotives. Total production was 800 of these units, equally divided between the French version and the German.

This engine is a favorite of mine. Despite its being a Japanese model of a French locomotive, it is quintessential 1930s, British gauge-1 technology. The Smithies boiler, first designed by Fred Smithies, has been a mainstay for decades. Basically a can of water inside an outer shell that contains the fire, this boiler is perhaps the simplest internally fired boiler to build. It is reliable, as well, though not as efficient as other types.

As with a full-size locomotive, the firebox is at the rear of the boiler. There are three large wicks within, fed by an alcohol tank carried in the bunker behind the cab. Having an internally fired boiler, the engine requires an auxiliary fan to draw the combustion gases forward and out the stack until enough pressure -- about 20 psi -- is raised to turn on the locomotive's own blower. Once this is done, the engine becomes self sufficient and the fan can be taken away. A satisfying, deep-throated roar can be heard.

Blow-off pressure is around 45psi. Once that is reached, the throttle can be slowly opened while the engine is pushed forward. Since the cylinders are cold at this stage, there will be some hot water ejected from the stack. It's a good idea to stay clear (the voice of experience here). Once the cylinders have heated up, the engine takes off under its own power.

This engine can be kept in steam indefinitely through the use of a trackside pump, which must be attached to a fitting beneath the cab when the water runs low. Otherwise, the fire must be dropped and the loco refilled through one of the safety-valve holes.

Alcohol is fed to the burner through a chicken-feed system. Thus, the fuel tank can be refilled while the engine is under steam, too.

In action, this is a wonderful locomotive. It is easily controllable, powerful, and it has a clearly audible but somewhat muffled exhaust beat. The engine looks terrific loping around wide-radius curves. It can be left alone and will not run away.

My particular engine has some problems that I've not yet figured out. It travels better in forward gear than reverse, which is most likely a matter of properly adjusting the valves. I've just not taken the hour or so required to do it.

However, there is another, more baffling problem. Steam pressure comes up fine with the engine's blower. But, when the engine is under way and the blower is turned off, pressure drops. This suggests two possibilities. There may be a steam leak in the drive system or, more likely, there is a problem with the drafting of the engine. If the exhaust pipe is not properly aimed and placed, the exhaust blast will not draw the fire, causing it to burn improperly, which, in turn, causes the pressure to drop. This is the area I'll be examining.

| Specifications | |

| Builder | Aster Hobby Company |

| Date built | 1978 |

| Gauge | 45mm |

| Scale | 1:32 |

| Boiler | Smithies, silver-soldered copper |

| Fittings | Two safety valves, displacement lubricator, throttle, blower, water glass, pressure gauge |

| Fuel | Alcohol |

| Working pressure | 45 psi (3 bar) |

| Cylinders | Two double acting, fixed cylinders, D-valves |

| Valve gear | Walschaerts, operated via a reversing quadrant in the cab |

| Duration | Approximately 15-20 minutes unattended -- can be kept in steam indefinitely |

| Minimum radius | 10' (3 meters) |

| Dimensions | Length over end beams, 16.75"; width, 4"; height, 5.5" |

CENTER: Alcohol is added to the bunker tank. Alcohol (or "meths") in Britain is supplied purple. In the US we have to color it ourselves to avoid confusing it with water.

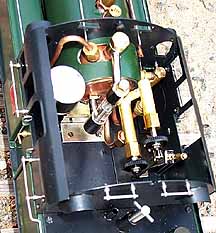

RIGHT: This loco has a well-fitted cab. The white circle at the left is the upward-facing pressure gauge (the roof has to be off for it to be read). Next to it is the water glass. The upper valve is the blower and below it is the throttle. The reversing lever can be seen at the right, under the cab window.

RIGHT: A battery-powered fan draws the fire until pressure is raised.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2000