Back to Sidestreet Bannerworks

December 2002

Mike Gaskin's Ceylon

by Marc Horovitz

This model is based on a Bagnall 0-4-0 tank engine built in 1906 for the 2'-6"-gauge Ceylon Irrigation Dept. The prototype had Bagnall-Price valve gear. The prototype had no tender. The one on the model was added by Mike Gaskin and is based on those attached to the Mansfield-type 0-4-2s built for Egypt Sugar Factories in 1907.

The model

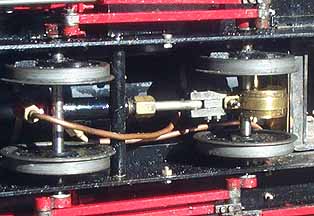

This is one of two similar locomotives that Mike Gaskin made. (The other, coincidentally, also resides in Colorado.) The second engine does not have side tanks, but is otherwise close to Ceylon. Ceylon is fitted with a locomotive-type boiler containing seven tubes and one superheater flue. The smokebox front is not hinged and must be pulled off for maintenance. There is a proper grate in the firebox, below which is an ashpan. These can be quickly dropped at the end of a run by undoing a simple latch. The four-wheel tender carries both coal and water, and is fitted with a hand pump. There is an axle pump on the engine's second axle, which is tied into a regular bypass system. The bypass valve is in the cab, as are the blower and throttle valves and blowdown. This engine is as fully featured as a small, full-size locomotive.

Mr. Gaskin used reliable Roundhouse cylinders to power the engine. The valves are controlled via slip-return-crank valve gear (similar in operation to slip eccentrics). Workmanship is good throughout and this is a relatively easy locomotive to operate, with all controls readily at hand. One funny thing about the engine is the dome, a standard Roundhouse unit, which is purely cosmetic. It is strapped to the boiler with a boiler band, like a birthday hat. And, like a silly hat, it sometimes goes astray, sliding to one side or the other and giving the engine a decidedly odd appearance.

The run

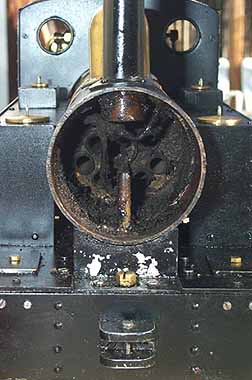

This was a perfect steamup day. Temperature in the mid 50s; a cloudless, brilliant blue sky; and crystal-clear fall air. I began prepping the engine by removing the smokebox door and cleaning the flues with the flue brush. I cleaned out the smokebox, as well. What ends up in the smokebox is not just ash. There are a lot of cinders and coal dust, all mixed with steam oil and forming a viscous, tarlike goop. Once this was done, I droppd and cleaned the grate.

I filled the tender with water and commenced pumping it into the boiler. I'd not run the engine in quite a while and one of the balls, either in the pump or the check valve, had stuck closed. After a couple of strokes, however, it popped free and water began to fill the boiler. After it had risen to the proper level in the glass, I filled the displacement lubricator with steam oil. This is on the front pilot deck and has no drain, so I had to suck the water out with a syringe.

After oiling all around, the engine was ready. The firebox was loaded with the finest mesquite charcoal, soaked in kerosene, and the fire was lit. In due course, pressure rose to the point where the fan could be removed and the blower took over. After 15 or so minutes of tending the fire, all of the charcoal had been replaced with coal and we were ready to go. I opened the throttle, turned down the blower, and gave the engine a little push forward to set the valves and clear the cylinders. After some brief coughing and spluttering, it was away, chuffing softly. After a few rounds, I added some more coal and closed the bypass valve, letting the engine's axle pump refill the boiler. After a few more rounds a short train was tied on the back, and the next hour or so was spent tending the fire, adding water, and just generally enjoying myself. No better way to spend an afternoon.

For additional information on coal firing, click here.

|

|

|

| Builder | Mike Gaskin (England) |

| Date built | Circa 1990 |

| Gauge | 32mm (gauge 0) |

| Scale | 16mm |

| Boiler | Locomotive type |

| Fittings | Safety valve, throttle, pressure gauge, blower, water glass, blowdown, tender pump, axle pump, bypass system |

| Fuel | Coal |

| Blow-off pressure | 50 psi |

| Cylinders | Two double-acting D-valve |

| Reversing gear | Slip return crank |

| Lubricator | Displacement |

| Dimensions | Length (with tender), 18"; width, 4-1/4"; height, 6" |

Below: Before the start of each run the flues must be cleaned with a brush and crud removed from the smokebox as much as possible. When running, if all else is well, declining performance is a certain indicator of choked flues.

Below: The underside of the engine with the grate removed. This is an example of a "dry" firebox. There is only a water leg on the front face -- the other three sides are "dry".

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2002