Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

January 2004

Peter Angus’s overtype

by Marc Horovitz

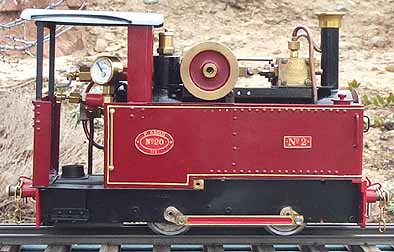

Peter Angus has become well known, particularly in Britain, for building one-off models of unusual locomotives. His most recent engine, as of this writing, is works Nº 139. In more recent years, he has built models of specific prototypes more than freelance engines, but in earlier days he did build some freelance models. The engine under scrutiny here is one of those.

Overtype locomotives -- engines that had the cylinder(s) atop the boiler -- were few and far between in the prototype world, but there were some. Aveling & Porter, the British manufacturer of steam tractors and road rollers, once applied their talents to the rails, coming up with some unusual engines. (Click here for a picture of one.)

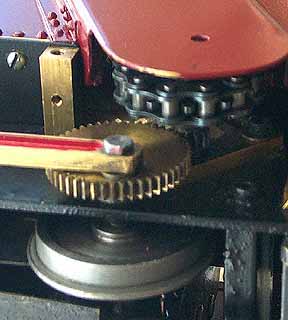

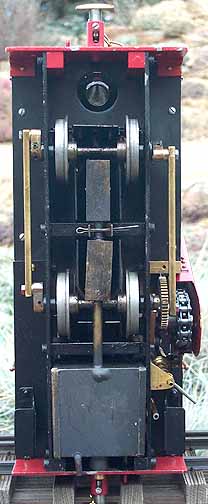

Peter Angus's engine is not a model of any specific prototype and, as such, is much more attractive than full-size overtypes. My example (works Nº 20) has a single cylinder atop the boiler that runs a crankshaft, to which is attached a sprocket that drives a chain to another sprocket on a jackshaft near the rear axle. On this shaft is a pinion, which drives a large external gear on the axle. The overall reduction is around 5.5:1, making the engine a smooth, slow runner. The two axles are connected by conventional side rods.

Peter relies on other manufacturers for most of the working parts of his engines -- gears, cylinders, fittings, etc -- while he concentrates on the body work and the mechanics of getting everything to work properly together. He is a meticulous craftsman and all of his engines that I have seen run superbly. He often uses steam engines from Maxwell Hemmens, but this particular locomotive utilizes a Roundhouse cylinder, fittings, and other parts.

The single cylinder is placed very close to the crankshaft, giving the short drive rod a lot of angular motion. If the engine were in constant use, this would be a cause for concern and a source of wear. On the bright side, though, it makes for a compact and good-looking unit. A large brass flywheel gets the engine past the dead spots in the cycle. Reversing is accomplished through a slip eccentric. The boiler has the usual fittings.

The run

The weather in Denver today was mild for winter, with the temperature in the high 40s and a partly overcast sky; a good day for steaming. The engine was prepared in the usual way. With most of the works on top, lubrication is easy. With all the vital fluids topped up, the fire was lit. After a while -- perhaps 10 minutes, it being a cool day -- pressure was up to nearly 30 psi. Since the cylinder is atop the boiler, it receives the benefit of the hot exhaust gases from the fire beneath the boiler. It takes little to clear the condensate, since there isn't much.

Since the engine has but one cylinder, it must be physically encouraged to go. After a flick or two of the now-toasty flywheel, the engine was off. Visually, this is a wonderful engine. It runs at a nice, slow speed, while its various parts up top frantically flail around. The unsightly drive chain is covered by a chain guard, which adds lots of character to the left side of the loco. The flywheel adds charm to the right.

The run was marvelous. The engine ran smoothly, lap after lap. The exhaust line from the cylinder is routed directly up the stack, which poured out great clouds of steam on this cool afternoon. The run lasted a good half hour and would probably have gone on longer. It was an ideal way to begin the new year.

.

|

|

|

| Builder | Peter Angus (England) |

| Date built | 1987 |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Pot |

| Fittings | Safety valve, throttle, pressure gauge, blowdown |

| Fuel | Alcohol |

| Blow-off pressure | 30 psi |

| Cylinders | One, double-acting D-valve |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Dimensions | Length over end beams, 8-1/2"; width, 3-1/2"; height, 6" |

Above: The left side of the locomotive is unusual because of the distinctive, angled chain guard.

Below: The right side of the engine is slightly more conventional.

.

The front of the engine. The smokebox handle is actually a valve handle. The smokebox door itself is a dummy -- there is actually a gap between it and the beginning of the boiler. All the rivets are real. The end of the chain hanging from the coupler should properly have been hung on the hook above the buffer.

Below left: The single cylinder sits atop the boiler in plain view, making this a fascinating engine to watch. Note the functional oil cups on the crankshaft.

Below right: A large gear on the trailing axle is powered by a pinion on the chain-driven jackshaft.

.

.

.

With all the works on top, the underside of this engine is pretty plain. The cotter pin in the middle helps to retain the burner. The engine was built to run on 32mm-gauge track.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004