Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

April 2004

Deryck Goodall's Usk

by Marc Horovitz

Usk (named after a Welsh river) is a charming interpretation of the de Winton quarry engines. De Winton was a builder of industrial locomotives and quarry equipment in Great Britain, starting around 1868. The company’s engines were widely used in the Welsh quarries and some may even have been exported to the US. The prototype locomotive had a two-cylinder steam motor attached vertically to the boiler and geared to one axle. The engine was small enough to be easily managed by one man. At least one, Chaloner, has been preserved in operating condition. A photo of it can be seen here on the Sharpo's World web site.

The model

This model is a tiny thing, neatly made in a workmanlike manner. It uses a Mamod flatcar as its chassis. The wheels appear to be Mamod as well, but have been rebushed with brass bushings and are now secured to the axles with set screws. The engine is 0 gauge at present but, thanks to the set screws, could be regauged to Nº 1.

Alcohol is the fuel of choice for Usk, and a fuel tank is carried below the footplate at one end. A single, annular-ring burner heats the internally fired vertical boiler. The top of the boiler (effectively the smokebox front) comes off, revealing a central flue surrounded by eight additional flues. The boiler is fitted with a proper exhaust nozzle as well as a blower. Other fittings include a water glass, safety valve, pressure gauge, filler valve, and throttle.

The steam motor is a single, double-acting oscillator that drives a flywheel. This is geared to the axle about 4:1 through an idler gear. The idler enables the motor to rotate in the same direction as the wheels. Reversing is accomplished through the usual rotary valve, this one mounted on the motor. A displacement lubricator between the throttle and the cylinder keeps the piston well oiled.

I built a traveling/display case for the engine that holds it securely enough for it to be packed in checked baggage. The engine's compact size makes it a good choice to take when luggage space is at a premium.

The run

Usk has seen a lot of use and it suffered a mishap at a show a few years ago. The solder joint between the fuel tank and the burner broke (or so we thought), spilling meths along the track. On hot days, alcohol will vaporize out the fuel filler tube and sometimes ignite. The flame, being invisible in the sun, has done some damage to the paintwork.

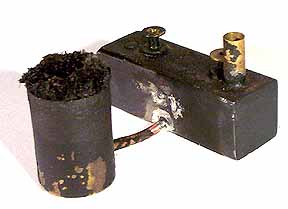

Today I removed the tank/burner assembly and had a good look at it. I discovered that the problem was not in the joint between the tank and the burner tube, but with the tank itself. It had been made, not of brass, but of tinplate (!) and had rusted through from the inside. Several tiny holes were visible from the outside. I figured that I could caulk them with soft solder, and that would get us through today's run. I filled the holes, then did a quick test. All seemed well, so we repaired to the track for the run.

Usk is a wonderful runner. Despite its single oscillating cylinder, it is a sophisticated locomotive and requires a suction fan for starting. After the usual preparations, the fan was duly dropped into the stack and the fire was lit. Pressure came up quickly thanks to the many-flued boiler. I removed the fan, turned the blower on, and pressure continued to rise. When it got to about 40 psi, I closed the blower and opened the throttle. Usk moved off with hardly a bump.

The first 30 feet were the best part of the run. It was then I discovered that the fuel leak was, in fact, not mended. Alcohol had seeped out around the bottom of the tank and ignited. This boiled the fuel in the tank (alcohol boils at around 170 degrees F), which erupted out the filler hole and promptly burst into flames. I quickly dashed around to the other side of the railway and grabbed the pump bottle of water, only to find that the pump mechanism had quit working.

About this time, my friend Rich called out, "Hey, you've got a good fire going over here, too!" The mishap had occurred on the big bridge and burning meths cascaded through the ties, setting fire to the foliage below. While I ran into the shop for the big water bottle, Rich busied himself by stamping out the burning garden.

Both fires were eventually extinguished. The garden will recover in time. Damage to the engine was mostly to the paintwork, which wasn't that wonderful to begin with. Needless to say, I'll have to make a new tank and probably a new end plate, too. Oh, well. . . it was an eventful afternoon.

.

|

|

|

| Builder | Deryck Goodall (Great Britain) |

| Date built | Circa 1996 (?) |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Vertical, with 9 flues |

| Fittings | Safety valve, pressure gauge, water glass, blower, throttle, filler valve |

| Fuel | Alcohol |

| Blow-off pressure | 50 psi |

| Cylinders | One, double-acting oscillator |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Dimensions | Length, 6-3/16"; width, 3-1/8"; height, 6" |

Above: The (not) repaired burner. The tank, which is made of tinplate, rusted through in several places. The patches were made with soft solder.

Right: The locomotive is propelled by one double-acting oscillator geared to the axle. To the left of the cylinder, on the boiler, is the filler valve.

.

Left: The reversing valve on the cylinder column and the in-line lubricator. Right: Pressure gauge, water glass, and safety valve. The little handle on the right is for the blower, the one on the left is the throttle.

.

Above: The inner workings of the boiler. Nine flues bring the gasses through the boiler and provide plenty of heating surface. Pressure comes up quickly in this engine. Starting requires a suction fan.

The tube coming in from the left is the blower line. On the right is the exhaust line from the cylinder. Both keep the draft up when the engine is in steam.

Left: The annular-ring burner is clearly visible in this under view.

.

.

.

Back to

Loco of the Month home page

Back to

Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004