Back to Sidestreet Bannerworks

September 2000

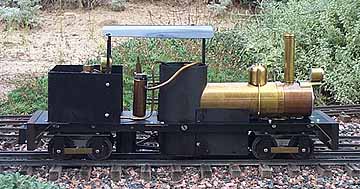

The Lindsay Shay

by Marc Horovitz

Larry Lindsay, a New Zealander residing in Denver, Colorado, built his first Shay in 1986. This engine was written up in the July-August issue of GARDEN RAILWAYS of that year. His initial locomotive utilized Mamod cylinders and a scratchbuilt, silver-soldered copper pot boiler. It had a four-wick burner (production engines had three) and was geared 28:10. On its inaugural run, “. . .it trotted four circuits around Norm Grant’s garden railroad with three LGB flatcars. It ran up hill and down dale, hardly varying in speed.”

The next year, in conjunction with Mike Bigger of Narrow Gauge Machining, Larry started work on a commercial batch. Some of the first of these locos were shown at the 1988 Garden Railway Convention in Denver. After building five or six engines entirely by hand (Larry did all the assembly work himself) Mike and Larry ordered the deck plates and fireboxes from a local company, Denver Sheet Metal. Mike made the initial batch of wheels, but later shopped them out to a screw-machine company in Michigan.

Larry and Mike worked together for about three years, during which time 18 or 19 Shays were produced. After they separated, Larry finished around three more, bringing the total count to perhaps 22. With the exception of one or two 0-gauge engines, all were gauge 1.

Yes, it’s a lefty

During the production of the Shays, Mike Bigger inadvertently countersunk one set of frames on the wrong side, resulting in a reversed set of frames. This engine, before it was even built, was offered to me. Always a fan of the odd and unusual, I accepted, and the locomotive was finished up as a left-hander (of which there were one or two prototypes). Aside from being a mirror image of other Lindsay Shays, this engine is exactly the same in all other features.

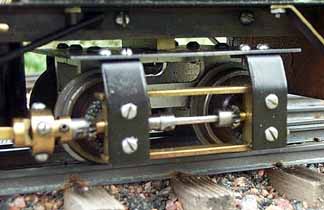

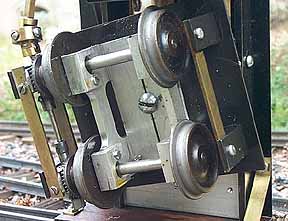

The locomotive features two, double-acting oscillating cylinders operating from a single port block. An external-spring arrangement keeps the cylinders tight against the block. Reversing is effected through a traditional rotary valve mounted atop the motor unit. It is controlled by a reversing lever in the open cab.

The boiler resembles a traditional Shay T-boiler, but the “T” part holds no water. It acts as a receiver for the rear of the longitudinal pot boiler and forms a sort of firebox around it. “Porcupine quills” are fitted to the pot boiler to help draw heat into it. The firebox extends forward about half the length of the boiler and a three-wick burner is contained therein.

A large, cylindrical fuel tank is carried in the engine’s bunker. This feeds a sump below the deck via a standard chicken-feed system.

The trucks are unusual in that they actually have inside frames. On the cylinder side of the engine, an auxiliary frame holds the gear assemblies. On the off side, the exterior frame is a dummy.

Performance

I ran my engine just prior to writing these notes. It had not been run for ten years or longer. I replaced the original fiberglass wicks with asbestos, oiled it all round, and filled the boiler with distilled water and the fuel tank with alcohol.

After six or seven minutes, when pressure came up to about 20 psi, I closed the fuel valve and topped up the tank with alcohol. I reopened the valve and opened the throttle. Steam condensed in the cylinders and water squirted from the stack. After a few jerky revolutions of the engine, the cylinders heated up and the action smoothed out. After traveling just a few feet, the locomotive began to run as smoothly as it had the last time it had been on the track, a decade ago.

Since both speed and direction are controlled from the lever in the cab, the throttle is very touchy. It takes little movement to cause a great change in speed. However, the engine is controllable and it ticked around my track for almost 30 minutes before running out of fuel. A sewing machine comes to mind when describing this locomotive. The Shay has a silky action at prototypical speeds and is capable of hauling a reasonable train. These engines are much loved by their owners and they are seldom seen on the second-hand market.

| Specifications | |

| Builder | Larry Lindsay |

| Date built | 1988 |

| Gauge | 45mm |

| Scale | 1:24 (approximately) |

| Boiler | Pot boiler with porcupine quills |

| Fittings | Safety valve, pressure gauge |

| Fuel | Alcohol |

| Working pressure | 20 psi |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve on top of motor unit, exchanges admission and exhaust |

| Duration | 25-30 minutes |

| Minimum radius | 3' |

| Dimensions | Length over end beams, 14.25"; width, 3.5"; height, 6.25" |

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2000