Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

September 2004

Archangel Vale of Rheidol 2-6-2T

by Marc Horovitz

This is a model of one of a pair of locomotives produced by Davies & Metcalf (Manchester) in 1902 for the Vale of Rheidol Railway when it first opened. The 1' 11-3/4"-gauge line was originally built to serve the lead mines in the Rheidol Valley of Wales. Both the engine and the railway underwent significant changes throughout the years. The railway is in existence today, running much modified engines over its nearly 12-mile length.

The model

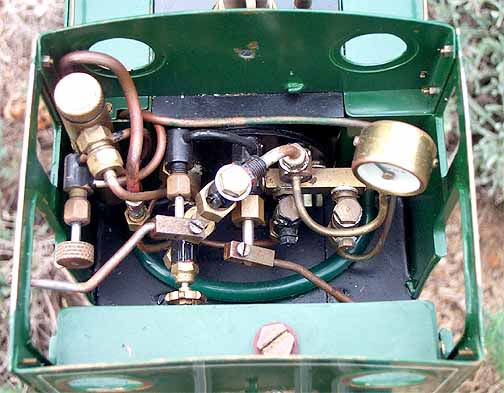

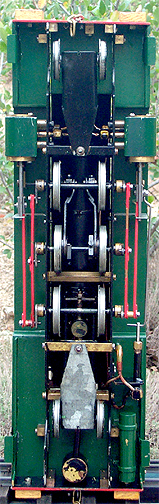

Like most Archangel models, this locomotive was offered in a variety of variations. The one under examination today has the more sophisticated internally fired, multi-flue boiler. A simpler pot boiler was also offered. Because of the type of boiler fitted to this engine, it has more amenities than the pot-boilered version. These include all the usual boiler fittings (safety valve, water glass, pressure gauge, blowdown valve) plus a blower to create draft, working side tanks, and two pumps; a hand pump in the left side tank and a rather unsightly crosshead pump, also on the left side.

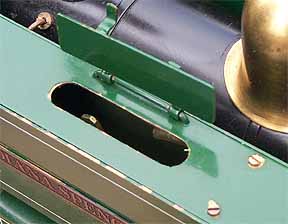

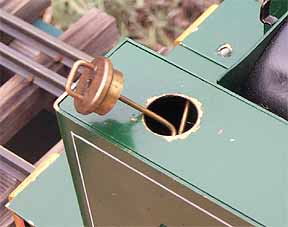

The crosshead pump is tied into a bypass system, with water being controlled by a valve in the cab. (A bypass system is a circuit, usually consisting of a pump, a needle valve, and its associated plumbing. The pump is actuated by the motion of the engine and the bypass valve allows it to pump water into the boiler, back into the tank, or a little of both. When you get to know your engine well, you can adjust the bypass valve to keep the boiler level constant while the engine is in motion.) A displacement lubricator also resides in the cab, as does a large alcohol tank with a drip-feed system to a sump below the footplate. Fuel flow is controlled by a screw on the rear end beam.

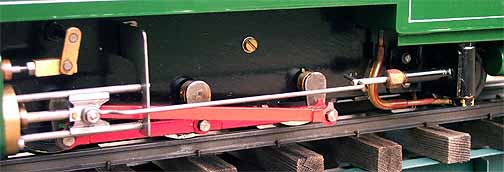

Given the complexity and sophistication of the boiler, the valve gear is remarkably simple. D-valves are controlled by slip eccentrics on the middle driven axle. Rocker arms bring the motion outside the frames.

Although the detail level of the model is relatively low, it is a reasonable rendition of the prototype in its early years. The proportions are accurate and the model conveys the massiveness of this rather large narrow-gauge locomotive. The engine is named Lady Diana Spencer, after Diana, who had become the Princess of Wales two years before.

The run

Run day was moderate and still. I prepared the engine by filling the lubricator and the fuel tank with their appropriate fluids. I filled one side tank with distilled water, allowing the balance pipe to fill the other. I then used the hand pump to fill the boiler. The water glass proved unreliable (and it sat too high on the backhead, anyway), so I had to go by feel.

Once all was in readiness, I plunked the engine on the track and dropped my trusty Aster suction fan into the stack. I unscrewed the drip valve on the fuel tank a few turns to allow fuel to flow into the sump and then to the two burners. Then I squirted a little meths onto my igniter, lit it with a match, turned the fan on, and lit the fire.

It took quite a while for pressure to come up 25 pounds -- 10 minutes or so. Once that point was reached, I turned on the blower and retired the fan. Several more minutes elapsed before pressure reached blow-off at 75 psi. I opened the throttle and was rewarded with a hot shower, proving the unreliability of the gauge glass. Once the priming had cleared and the cylinders warmed up, the engine moved smoothly off.

Running this locomotive is a joy. It is powerful, yet controllable. Throttle lever and blower lever are easily accessible on either side of the cab. The bypass valve is also readily at hand when wanted. The engine will creep along as long as you want it to, with the blower cracked, or it will tear around much faster than I was comfortable with. Running it at a prototypical speed was easy, and it was a pleasure to watch it go, lap after lap. It ran equally well (and controllably) in either direction.

Because of the sophistication of the entire system, the engine could easily be kept in steam all day long, pausing for water and fuel every half hour or so. Because of the way it is designed and built, in addition to its sterling qualities as a runner, I think this locomotive marks a high-water point in Archangel production. It combines all of the positive qualities that made Archangel engines popular, with none of the negatives. It has all the features even the most die-hard steamophile could wish for, yet the engine is relatively tame in operation. And it faithfully captures the mass and bulk of the prototype while being graceful and elegant in motion. Who could ask for more?

.

|

|

|

| Builder | Archangel Models (UK) |

| Date built | 1983 |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Internally fired, multi-flue |

| Fittings | Safety valve, water glass, pressure gauge, throttle, blower, hand pump in tank, crosshead pump, bypass system, blowdown |

| Fuel | Alcohol |

| Blow-off pressure | 75 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Dimensions | Length, 14-1/8" over end beams; width, 4-1/8"; height, 5-3/4" |

.

.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004

.