Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

October 2004

Colin Binnie's tram, Victoria

by Marc Horovitz

Victoria was the first locomotive (one of two) owned by the Plynlimon & Hafan Tramway, a little known railway in the Leri Valley of Wales. The 7+-mile-long, 2'-3"-gauge line was opened in 1897 and closed just two years later when the lead mining business didn't pan out (although it did become lucrative some years later).

Victoria, an 0-4-0T, was an unusual locomotive, to say the least, with its oddly shaped body and vertical boiler. Unfortunately, it did not survive and little is known about it.

The model

This model was constructed by the well-known British builder, Colin Binnie. Mr. Binnie says: "I built the engine around 1976 for Doug Jones ( brother of Peter), as a simple but reliable steamer of externally scale appearance. It was the first loco I built with an enclosed ceramic gas burner. The burner consists of a pan with the mixture tube extended across the diameter. The tube is cut away adjacent to the bottom of the pan to act as a diffuser. The top of the pan was fitted with a piece of ceramic from a commercial space heater. Needless to say I would not do it quite that way today."

Victoria is basic in the extreme. There is a gas-fired vertical boiler of unusual design, with the chimney exiting the side of the boiler near the top (see the photos). A safety valve (the boiler's only amenity) is located in the middle of the top plate, and doubles as a filler valve.

The locomotive has one of Mr. Binnie's oscillating motors mounted vertically next to the boiler and geared to the driving axle. The steam motor is controlled by a rotary valve built into it, which also serves as a throttle. There is a dead-leg lubricator with a drain, to keep the engine oiled.

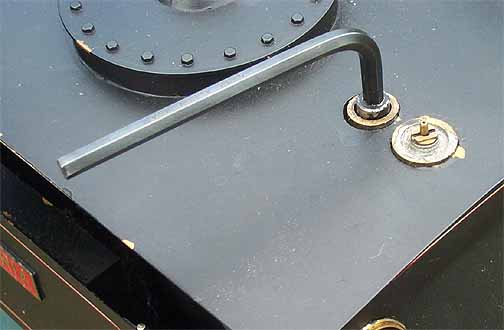

The jet squirts gas into an orifice in the side of the ceramic burner from a distance of about half an inch. The burner is entirely enclosed. The boiler is a shell within a shell, the outer shell being a sort of all-around firebox. The gas tank is filled through the roof and the gas-control valve requires an allen wrench to operate it. Body work is plain and neat, and the engine is fitted with unsprung buffers.

The run

With fall approaching, the weather on run day was pleasantly warm, in a coolish sort of way, under overcast skies. I confess that I had never run this engine before, although it had been here for several years. It is an odd duck through and through. The safety valve/filler plug sits down in a hole and must be removed with pliers. The lubricator hides behind a wall and is all but inaccessible. The drain has a fiddly little screw that must be dealt with. This did not bode will.

I eventually filled the boiler and lubricator. Filling the large gas tank, at least, was straightforward. When I first opened the gas valve, there was no sound—the jet was clogged. A little compressed air solved that problem. With the jet cleared, I opened the valve again and heard the satisfying hiss of gas entering the burner. I struck a match at the stack and the fire snapped back loudly. . .and instantly went out. I tried several more times at different gas settings, with the same result. I finally learned that you have to open it up wide for the fire to catch. Once it has, though, and the ceramic is glowing red, you can turn the gas down to almost nothing.

With the fire finally lit and all seeming well, I set the engine on the track and waited for pressure to build. As there is no pressure gauge, I had only the safety valve as an indicator. Once it began to weep steam a little, I moved the control lever forward. The engine wanted to go backward. OK. I moved the lever back and Victoria showed signs of moving forward. I moved the lever to the full-on position and gave a push. Victoria, much to my amazement, moved smoothly off.

Learning a new engine is always fun. This one turned out to be a prodigious steamer and an excellent runner. There is audible gear noise, which, to my mind, adds to the quirky charm of this locomotive. The control lever is very free—a little too free, actually. As the engine ran, the lever would vibrate toward its center-off position, slowing the engine. At first I thought it was steam shy, using all it had in the starting burst. However, when I discovered the problem and was able to correct it a little, the locomotive ran smoothly at any speed. I normally don't like to use the reversing valve as a throttle, but on this engine it works pretty well. Slow, smooth running is not a problem.

So, after an inauspicious beginning, Victoria proved to be a delightful locomotive, running smoothly and controllably for a good 20 minutes or so. I suspect that as I become more accustomed to its habits, performance should improve accordingly.

.

|

|

|

| Builder | Colin Binnie (UK) |

| Date built | circa 1976 |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Vertical, with ceramic burner |

| Fittings | Safety valve |

| Fuel | Butane |

| Blow-off pressure | 20 psi (estimated) |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve on steam motor |

| Lubricator | Displacement (dead leg) |

| Weight | 3 lbs., 13 oz. |

| Dimensions | Length, 8-1/8" over end beams; width, 4-1/2"; height, 6-1/4" |

.

Above: The gas filler valve is the usual bit of hardware. However, the control valve has the unusual feature of having to be adjusted with an allen wrench. While somewhat awkward, it does make for very fine control.

Below: The top of the boiler. The safety valve resides in the hole in the middle. The smoke stack is immediately to the left. The exhaust line from the engine is routed up the stack as well.

The underside of the engine reveals the closed ceramic burner. The gas jet can be seen right in the middle of the left axle. It squirts gas across the gap, entraining air as it goes, into the burner. The system actually works quite well. The motor is geared to the right-hand axle, which transmits power to the other through conventional side rods.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2004

.