Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

August 2005

Maxwell Hemmens Porter

by Marc Horovitz

The H.K. Porter Company, established in 1866 as Smith & Porter, was one of the world’s largest manufacturers of industrial locomotives. The company is perhaps best known (to modelers, anyway) for its 0-4-0 saddle-tank engines, which have been reproduced in every scale by the thousands. The prototypes were produced by the thousands in different sizes and in several different gauges, from standard on down.

Over the years, Porter produced locomotives not only for US customers, but for those in 40 other countries as well. The company used standardized parts and often built locomotives on speculation, to have in stock for quick delivery when orders came in. Porter ceased locomotive production in 1950.

The model

Maxwell Hemmens was known for fine workmanship and questionable business practices. If customers could get past the latter, they were almost always pleased with the former. The company's model of the Porter is, at best, an approximation of the prototype. The proportions seem odd and the detail level is low. However, it is a well-made locomotive and a good runner.

The boiler is gas fired, with a single flue with cross tubes. The backhead is equipped with a pressure gauge, a water glass, and a throttle. The throttle valve has no handle and must be actuated by a special tool, which is awkward to say the least. The steam line passes through a standard displacement lubricator (with drain) and then runs forward through the flue pipe, which provides some superheat. Reversing is accomplished via a reversing valve between the cylinders, controlled by a handle in the cab.

A safety valve sits atop the boiler, inside the wooden cab, exhausting through a tube through the roof. This tube can be unscrewed and the roof slid off for cab access. The smokebox door opens—a nice feature. Cylinders are controlled by piston valves. The wheels are not spoked, but have curved slots in them instead.

The engine is provided with a large, unprototypical, wooden tender in which resides the gas tank. This tank has the usual control valve and an unusual safety valve, accessed by the removal of the wood load. The filler valve is unusual, too. To get to it, you have to unscrew and remove the control valve. Underneath is a standard filler valve. When the control valve is screwed back in place, it releases gas through the filler valve. Gas is fed to the burner via a silicon tube. The workmanship on the tender, as on the locomotive, is to a high standard.

The run

This engine hadn't been run in a long while, so I gave it a good oiling all around. I filled the lubricator with steam oil, and the boiler with distilled water through the safety-valve hole. I unscrewed the gas control valve and filled the large tank with butane. After setting the engine on the track, I lit the fire through the open smokebox door. It flashed back immediately.

This engine burns fairly quietly for a single-flue engine. Perhaps this is because the cross tubes act as sound baffles -- you don't get the impedance matching that you do with an unobstructed tube.

Anyway, pressure came slowly up to the blow- off point of 60 psi. The safety let go with a quiet hiss. I opened the throttle with the supplied tool, pushed the reversing lever into forward gear, and the engine was off with no hesitation -- too fast, in fact. This throttle setup is not to be recommended. There's no way at all to slow the engine down by just giving the throttle a flick as the engine passes. You have to grab the thing on the fly, fit the tool to the throttle valve, and close it a bit -- then repeat the process if that wasn't enough.

Once the speed was satisfactorily adjusted, the run proceeded without incident. The Porter is a smooth, quiet runner, and it ran unattended for probably 25 minutes or so, until the gas was exhausted. I ran off the residual steam, then opened the blowdown (with the same tool). This system was poorly thought out, as it blows down all over the cab floor. A pipe to the outside would not have been that hard to fit.

All in all, though, the engine performed well. It could be run at a sedate speed, throttle issues notwithstanding, and it is quiet in operation. It is easier to run with the roof off, but that doesn't look so nice.

.

|

|

|

| Builder | Maxwell Hemmens (Great Britain) |

| Date built | Early 1980s |

| Gauge | 1 (45mm) |

| Scale | 1:22.5 (give or take) |

| Boiler | Single flue with cross tubes |

| Fittings | Safety valve, throttle, water glass with blowdown |

| Fuel | Butane |

| Blow-off pressure | 60 psi |

| Cylinders | Two, double acting, piston-valve |

| Reversing gear | Piston reversing valve between cylinders |

| Lubricator | Displacement |

| Weight | 7 lbs. |

| Dimensions | Length, including tender, 16 5/8"; width, 4-3/16"; height, 6-1/8" |

While the cabinet-maker's cab and tender, along with other details, fail to capture the work-a-day essence of a full-size industrial Porter, this is nevertheless an attractive locomotive. The tender is fanciful in the extreme.

.

Below: The builder's plate is screwed to the side of the tender.

.

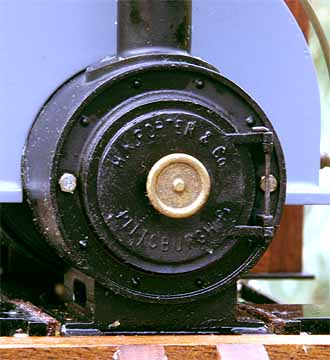

The smokebox closed. The words "H.K. Porter -- Pittsburgh" are cast into it. The door is opened by unscrewing the number plate.

.

With the smokebox door open, the fire can be easily lit. There is also access to some of the plumbing through the door.

.

Above: A close view of the cylinder with its piston valve. The valve is actuated by a rocker arm that carries the motion through the frame. Note the odd wheels -- curved slots instead of spokes.

Below: The valves are powered by eccentrics on the rear axle. The front axle is sprung. The long rod is the reversing rod, extending from the lever in the cab to the valve between the cylinders.

.

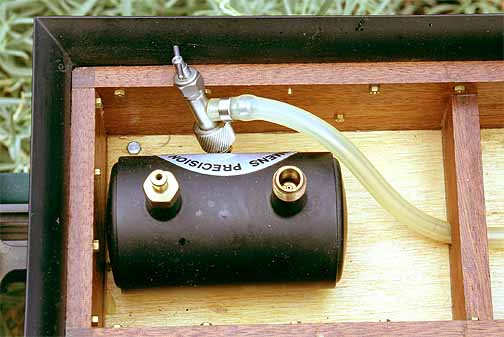

Above right: The tender without the wood load. The large gas tank is bolted to the floor. Behind the control valve is the tank's safety valve.

Right: To fill the tank with butane, the control valve must be unscrewed. Below it is a standard filler valve.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2005

.