Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

July 2006

Graham Stowell's Sedgemoor

by Marc Horovitz

This engine has no particular prototype that I am aware of. It was named and numbered after the Battle of Sedgemoor in 1685. This took place in western England, where the Royal army, under Lord Feversham, destroyed the Duke of Monmouth's rebel army.

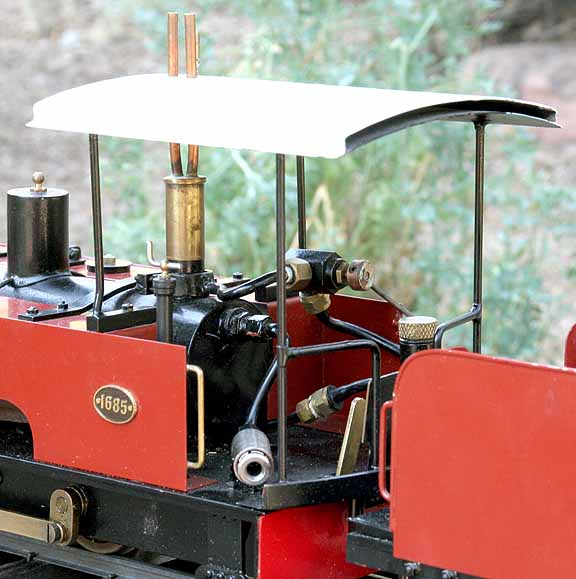

The engine was built on a chassis made by a short-lived British company called A.H. Collins. It has two, double-acting oscillating cylinders disguised by shrouds. Reversing is via the typical rotary valve between the cylinders, actuated by a lever in the cab. The locomotive is equipped with a throttle valve, a safety valve, and an ENOTs-type filler. Fuel is carried in the tender, in a tank beneath the floor. This communicates with the burner via a piece of silicon tubing. Cylinder lubrication is accomplished through a standard, in-line displacement lubricator, with a drain, on the footplate. The boiler is a pot, fired with a wick-type alcohol burner. The safety valve is shrouded and vented through the cab roof -- a nice touch.

The body features full-length side tanks (non functional) and an open, tropical cab with double roof sheet. The tender is completely open, and might have carried cane. It attaches to the engine with a simple hook.

The run

I had never run this engine before, as it had some mechanical problems. In some free moments I got into it and made some necessary tweaks, so today's run was a first for me, and perhaps a first for the engine as well.

It was really hot and still out. I went through the usual firing-up procedure and parked the engine on a bridge for lighting, which I did in the usual way. The first thing I noticed was that burning meths was dropping from the engine, setting the surrounding track and countryside alight. Not a good omen.

The engine has a simple pot boiler and, although the side tanks were stuffed with some sort of insulation, the paint soon started to darken. Steam came up in fairly short order and I opened the throttle. Sedgemoor made a halfhearted attempt at mobility, then stopped again. With ample encouragement (i.e. pushing), it finally got going, but with little enthusiasm.

A well-designed engine with oscillating cylinders should be as lively as can be. I seem to recall reading that the valve events on Collins locomotives were not all that could be wished for. This might well explain this engine's lackluster performance. Whenever the engine stopped, I could hear blowby.

Sedgemoor continued to amble around the track with the throttle wide open and the safety valve blowing for another twenty minutes or so. I refilled the fuel tank a couple of times and pumped some more water into the boiler via the ENOTs valve, but it was obvious the engine just wasn't interested. In the mean time, the paint continued to char and a passing bush knocked off the sole remaining nameplate (also discolored with the heat). It looks like a complete tear-down is in the offing. Some days are just like that.

|

|

|

| Builder | Graham Stowell (on a Collins chassis) |

| Date built | 1992 |

| Gauge | 0 (32mm) |

| Scale | 16mm |

| Boiler | Pot |

| Fittings | Safety valve, throttle, ENOTs filler valve |

| Fuel | Alcohol |

| Blow-off pressure | 30 psi (?) |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | Loco & tender: 6 lb. 6 oz. |

| Dimensions | Length (loco & tender) over end beams, 15-1/4"; width, 3-7/8"; height, 6-1/4" |

Above: The reversing valve is controlled by the lever protruding through the cab floor. To the left of it is the ENOTs filler valve.

Below: The result of the first run -- charred paint and a scraped-off nameplate. Oh, well. That's just the way it goes sometimes.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.