Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

September 2006

Wrightscale "Wren"

by Marc Horovitz

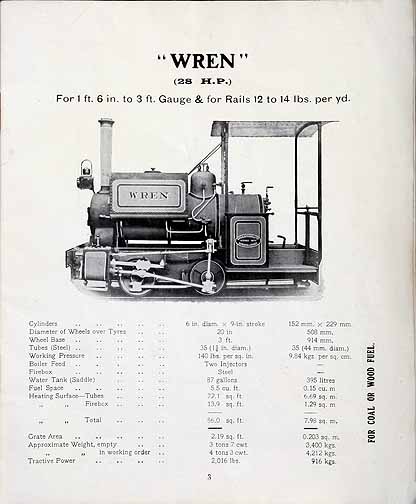

Kerr, Stuart was a British manufacturer of industrial locomotives, first steam, then diesel. The company was in business from 1881 to about 1930. They offered locomotives to run on many gauges of track, from 1'-6" through standard gauge. Stock designs were offered and the company published a catalog with photos and specifications of the engines, quite similar to a model-train catalog. (The page for the "Wren," from the 1924 catalog, is reproduced below.) The "Wren," at 3.5 tons, was the smallest engine the company made at that time.

It's interesting to me how some companies just seem to "get it right," aesthetically. Kerr, Stuart is one of these, along with John Fowler and Hunslet. Kerr, Stuart's locomotives are extremely attractive. Virtually all have pleasing proportions and the little ones are charming. It's a shame that more have not been preserved, but it's nice that accurate models, like the one presented here, have been made available to carry on the tradition.

The model

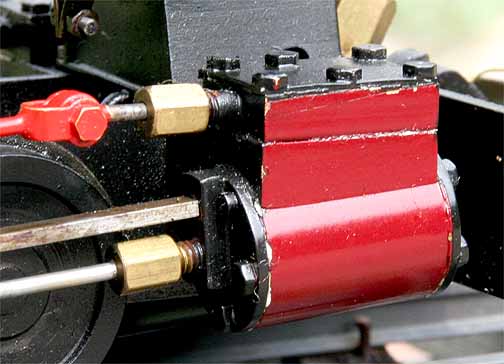

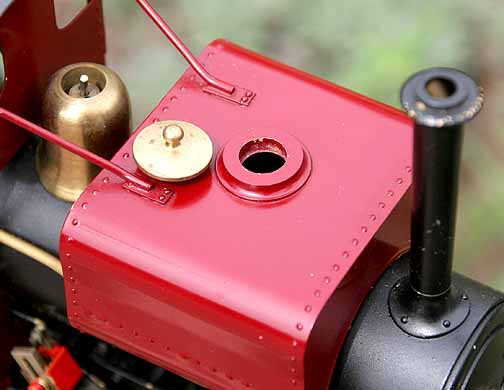

Wrightscale, run by Malcolm Wright, started life in Oxford but later moved to Scotland. Like Kerr, Stuart, Wrightscale produces mostly models of smaller, industrial engines. His "Wren" is exquisite. It has tiny cylinders, working Hackworth valve gear, and a gas-fired boiler. The gas tank is hidden in the back sheet, below the spectacles, and it is filled via an extension that comes up through the roof. Also projecting through the roof is the throttle extension. This keys loosely into the throttle itself and can be disengaged and removed for display, if one wishes.

Atop the boiler is a working water tank with a line to the backhead. When the engine cools down, the valve on this line (actually a vacuum tap) can be opened and the cooling boiler will suck the water in for the next run. Otherwise, the boiler must be filled by removing the safety vale (awkward). A displacement lubricator resides on the footplate and a condensate tank sits beneath the smokebox, between the frames. This makes for a cleaner-running engine.

The model, like the prototype, is just plain cute. Wrightscale got the proportions right and the tiny, working details make this engine an accurate rendition of the prototype.

The run

My engine hadn't been run in many years, so I didn't really know what to expect today. It was very dry, so I oiled it all around, paying special attention to the valve linkages. I filled the lubricator, then the boiler through the safety-valve hole. Gas was added through the appropriate hole in the roof and I was ready to light up.

The engine has two gas-control valves -- one on the tank and one on the burner. I closed the one on the burner, then opened the one on the tank. Then I slowly opened the burner valve while holding a match inside the cab. The fire immediately flashed into the firebox and was burning.

I set the engine on the track and did some cleanup while the pressure came up. Soon the gauge read 20 psi. I put the engine into forward gear (by pulling the reversing lever back!) and opened the throttle. The loco immediately showed signs of life. After a little to-ing and fro-ing to offer encouragement, it was off, running smoothly down the track.

Tiny engines have a reputation for being fast runners, usually out of control. Not so this. While it certainly will run faster than you'd ever want it to, it will easily throttle right down to a walk, even running light. It puttered sedately around my line until the gas was exhausted, at which point it slowed to a stop. It is a pleasure to run and fascinating to watch. It's a true gem in the world of mini steam locomotives.

|

|

|

| Builder | Wrightscale |

| Date built | 1988 |

| Gauge | 0 (32 mm) |

| Scale | 16mm |

| Boiler | Single-flue, internally fired |

| Fittings | Safety valve, throttle, pressure gauge, vacuum tap |

| Fuel | Butane |

| Blow-off pressure | 40 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Hackworth |

| Lubricator | Displacement |

| Weight | 2 pounds, 12 ounces |

| Dimensions | Length over end beams, 6-3/4"; width, 2-3/4"; height, 5-5/8" |

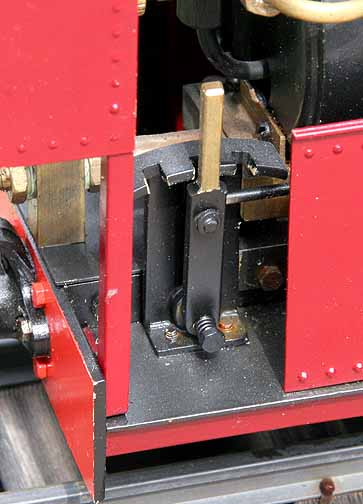

Above: The odd linkage between the throttle lever on the roof and the throttle can be seen here. A pressure gauge is tucked up under the roof. The gas tank is concealed by the backsheet.

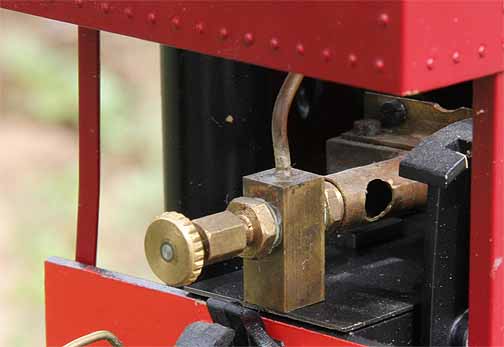

Above: The square saddle tank is functional. With the cover off, you can fill it with water. As the engine cools, the vacuum tap on the backhead is opened, and water in the tank is sucked into the boiler for the next run.

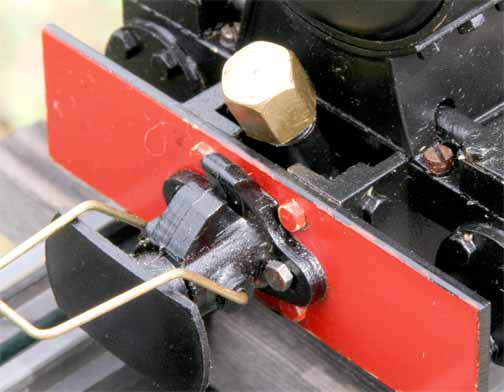

Left: The lubricator sits on the left-hand footplate. There is a cap on the bottom that can be removed for draining.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.