Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

November 2006

Merlin Matterhorn 0-6-0T

by Marc Horovitz

This 0-6-0T is a freelance model, made by Merlin as a somewhat unsuccessful attempt to tap into the LGB market with live steam. It is vaguely Germanic in appearance, with its boxy body, oval windows, and square sandbox astride the boiler. It has loop couplers that are compatible with LGB hooks, but otherwise mar the appearance of the engine. The loco is gas fired, with the fuel tank residing under the roof. The filler valve is accessed through a hole in the roof and the control valve for the gas is inside the cab. A square displacement lubricator with a screw drain sits on the footplate in the right hand door of the cab. The locomotive was offered only as a gauge-1 product. It was also offered with a whistle, although this one has none. (Thanks to Tag Gorton for some of this information.)

The engine is radio controlled, utilizing a single servo to control both speed and direction through a rotary valve. The two, double-acting cylinders are controlled by piston valves, so they can be reversed by switching the admission and exhaust lines, which is what the rotary valve does.

There is a banjo fitting on the backhead, to which both the pressure gauge and the steam line are attached. The steam line passes through the fire, providing some superheat, then goes directly to the rotary valve beneath the engine. Since there is no actual throttle to close, there is nothing to prevent the boiler from sucking oil back into itself when cooling. However, this does not seem to affect performance.

The radio’s receiver is in the cab. The servo is in the cab below the receiver. This engine was designed specifically for radio control and would be difficult to convert to manual operation.

The run

This was another of those engines that I've had for a while but never, run, so I had no idea what to expect. I fueled, oiled, and watered it in the usual way, then lit the fire at the stack. It immediately flashed back into the boiler. After eight or ten minutes, pressure had come up to around 40 pounds. I switched on the transmitter, then the receiver. The left-hand handle on the transmitter is spring-loaded to the center, which is “off.” I pushed the lever up and the engine moved smoothly off, with no jerking or jumping from condensate. I backed it up and coupled it onto a four-car train of LGB rolling stock, then reversed it again. Off it went, looking just right with its train of short European coaches.

Control was a little touchy, but with some practice, I was able to slow it right down and stop and start smoothly. Top speed was prototypically sedate, which was also nice. We had an enjoyable 20-minute run before the fuel was exhausted. It's possible the fuel tank was not entirely full, which would have given a longer run. So, although this engine looks fairly plain on the shelf, when in action with the right sort of train, it looks right at home in the garden.

|

|

|

| Builder | Merlin Loco Works (Wales) |

| Date built | Circa 1986 |

| Gauge | 1 (45 mm) |

| Scale | 1:22.5 |

| Boiler | Single-flue, internally fired |

| Fittings | Safety valve, pressure gauge, |

| Fuel | Butane |

| Blow-off pressure | 40 psi |

| Cylinders | Two, double-acting piston-valve |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 7 pounds, 6 ounces |

| Dimensions | Length over end beams, 11"; width, 4-1/8"; height, 6-5/8" |

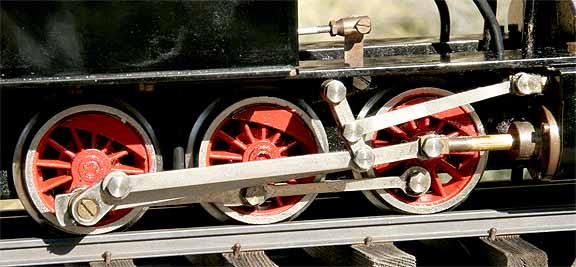

Left: The running gear. The piston valve is driven off a simple eccentric on the third axle via a reduction lever hung from the footplate. The valve gear itself is non-reversing.

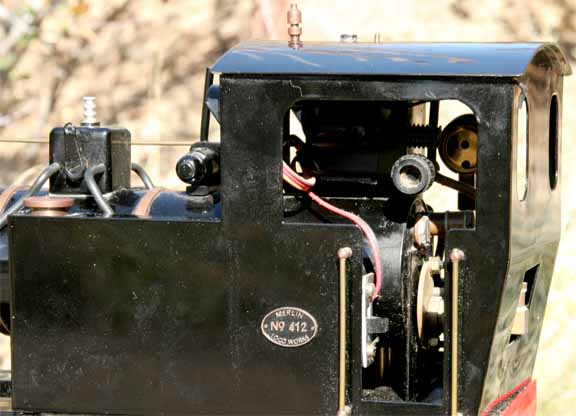

Below left: The right side of the cab. The pressure gauge and steam line are tied into the same banjo fitting on the backhead, which can be seen behind the pressure-gauge line. Below the pressure gauge is the lubricator. To the right of it is the radio receiver. Below the receiver, inside the cab, is the servo that controls the engine.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.