Back to Sidestreet Bannerworks

December 2000

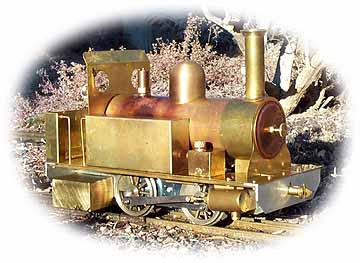

Einco/Lindale Sam 0-4-0T

by Marc Horovitz

Lindale Models began business in 1981 or thereabouts. In addition to Sam, the company produced Caledonia, an 0-6-0T, as well as machined parts for a 3-1/2"-gauge locomotive, Rob Roy, designed by Martin Evans. Aside from wheel arrangement and the fact that Caledonia had two working cylinders while Sam had only one, the engines were quite similar and used about 80% of the same parts. The engines were designed by John Turner, a competent and meticulous engine designer, while the company was run by his brother-in-law, Kevan Winward.

Jack Wheldon wrote a review of the then new Lindale engines in the British press. It was this review that called them to my attention. I contacted the company and became the US importer in 1981. The locomotives were available in both gauge 0 and gauge 1, but only as kits. The kits were simple to assemble (the instructions were entirely pictorial), requiring only basic tools. No soldering, drilling, or machine work was necessary. The wheels, originally nickel silver, were later replaced with cast-iron, as the nickel-silver ones tended to turn on the axles.

There seemed to be a fair amount of turnover in the company. I perused my 20-year-old files in preparing these notes and found that I corresponded with at least three people in the company over a two year period. Sadly, our relationship ended badly in 1982, and the company sank without trace shortly thereafter, having produced only the two different models.

The engine

Sam is a big, chunky 0-4-0. The one I currently own I acquired recently, though it is one of the earlier ones made, with cast nickel-silver wheels. It is nominally 16mm scale, but, for an 0-4-0T, is really oversize. However, I find its proportions pleasing and it has quite an industrial look about it.

The original locomotives, both Sams and Caledonias, were fitted with zinc-alloy side rods. These were fine for a few years, but soon the zinc began to do all the nasty things that zinc does, and the side rods fell to pieces. Most of these engines running today, including mine, have replacement side rods. Graham Stowell fitted steel rods to this engine.

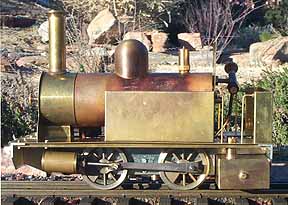

Sam is unusual in that it has only one working cylinder. That's not the unusual part—lots of engines have just one cylinder. However, on most of them, the cylinder is placed between the wheels so it can drive the engine symetrically. Sam's is outside, on the righthand side. The cylinder on the left-hand side is similar in appearance, but is a dummy. The only other engine like this that I can think of was Aster's first offering, the JNR 2-6-0, though no doubt there may be others.

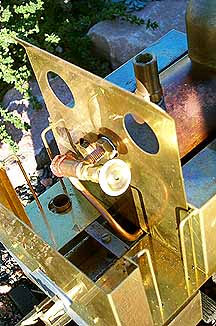

Another unusual feature of this locomotive is the fact that it has two throttles. There is a conventional, needle-valve throttle in the cab and a secondary throttle that chokes the exhaust as it leaves the cylinder. When used in combination, the pair make for an easily controlled locomotive. A rubber O-ring around the throttle knob in the cab is intended to keep it cool enough to comfortably handle (it doesn't!).

A massive fuel tank resides beneath the open cab. Three wicks heat the boiler, which is shielded only by the sheet-metal dummy side tanks. A boxy displacement lubricator sits on the right-hand footplate. All steam connections are of the banjo variety, simple and reliable.

Aside from the wheels, the engine uses no castings. It is made entirely of sheet metal and machined parts. The smokebox is simply a sheet-brass wrapper projecting from the front of the boiler. The knob on the front is the exhaust regulator. Reversing is via a slip eccentric, the eccentric being between the rear driver and the frame, similar to Roundhouse Engineering's current line of lower-cost locomotives. Sam has absolutely no insulation and, consequently gets very hot in operation. Reversing the loco is best accomplished with a stick.

Performance

Running Sam is simple and straightforward. The day I ran the engine was cold (upper 30s) and there was a slight breeze. I was concerned that performance would be affected, but I needn't have been. After the usual lighting-up ritual, steam was up after about eight minutes. I opened the throttle and pushed the engine a few yards to clear the condensate. It is a free-running locomotive, and took off right away. Because of its relatively large drivers, it had a tendency to run away until I got the right balance between the throttles. After that it was docile and well behaved.

The engine has a peculiar gait, shifting from side to side as it travels the rails. (This phenomenon is known as "boxing.") The single cylinder on one side exagerates the uneven forces that act on the engine, which contributes to this effect.

The boiler is a massive pot. That, coupled with the oversize alcohol tank, suggests a long runner. In fact, with only a couple of stops for the fuel to be topped up, Sam ran for over 40 minutes in the frigid weather. By the end of the run it was late in the evening and getting dark. The fire has little shielding, and tends to show itself at every opening. The last of the run was spectacular, with the engine spurting flame from between the frames, under the tank, and into the cab.

This is an unusual locomotive and a fun and reliable one to operate.

| Specifications | |

| Builder | Lindale Models (also called Model & Miniature Railways) Rochdale, Lancs., England |

| Date built | 1981 |

| Gauge | 32mm (0 gauge—also came in gauge 1) |

| Scale | 16mm (nominally) |

| Boiler | Pot boiler |

| Fittings | Safety valve, throttle, exhaust throttle |

| Fuel | Alcohol |

| Working pressure | 40 psi |

| Cylinders | One, single acting D-valve on right-hand side of loco |

| Reversing gear | Slip eccentric |

| Dimensions | Length over end beams, 9"; width, 4-1/8"; height, 6-5/8" |

Above: A closeup of the lubricator, which sports a knurled filler cap and a screw drain. This is a no-frills locomotive.

Right: The burner and the plumbing for the single cylinder can be seen here.

Above left: The locomotive kit came packed in a box decorated with some evocative graphics. Who "Einco" was, I never learned.

Above right: All steam connections throughout the engine were of the banjo variety. While this profusion of them is unusual, they are effective connectors.

Back to Sidestreet Bannerworks

This page and its contents Copyright Sidestreet Bannerworks, 2000