Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

December 2006

Aster's "Grasshopper"

by Marc Horovitz

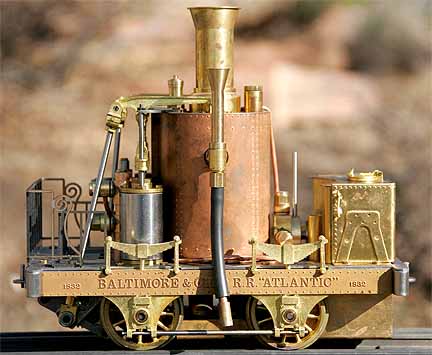

In the earliest days of railroading, back in the 1830s, locomotives were still being developed and there was no standard form. It was not uncommon for railroads to come up with their own designs and, back then, the Baltimore & Ohio was one of the leading railroads in the country. In 1832, Phineas Davis created Atlantic for the B&O. The engine had a vertical boiler and twin, vertical cylinders, each of which powered an overhead walking beam that was, in turn connected to a geared jackshaft via rods. The jackshaft was then geared to the axle. It was these walking beams atop the engine that gave it the nickname "Grasshopper."

The coal-burning locomotive was so successful that the B&O built 20 more to a similar pattern. The original Atlantic faded from history about 1836, but in 1893 the B&O rebuilt a similar engine, the Andrew Jackson, to resemble the Atlantic. This became a B&O "heritage" locomotive and was exhibited at various important exhibitions. It currently lives at the B&O Railroad Museum in Baltimore. It is this rebuilt locomotive that Aster has modeled.

The model

The Grasshopper is a real departure for Aster in many ways. It is the earliest locomotive they have ever offered a model of; it is, mechanically, perhaps the most unusual; it was supplied unpainted; and it was supplied with a coach!

The model is equipped with a vertical, internally fired boiler with four flues. It burns alcohol, which is carried in a tank beneath the footplate. The burner has four small wicks that correspond with the flues. Fittings are minimal, and include a safety valve, a check valve on the side of the boiler for external filling, and a level plug on the other side. There's an additional plug atop a stubby tube on top of the boiler. This tube amounts to a steam dome, as the steam takeoff pipe resides within it. There is no pressure gauge or water glass. (The prototype didn't have these amenities, either, we are told in the model's instructions.)

Like the prototype, the model is equipped with a pair of vertical cylinders mounted over one axle. These are controlled by piston valves. In the time-honored tradition of piston valves, reversing is accomplished via a rotary valve, which also serves as the throttle. Extensive use of banjo fittings is made for steam connections. These, while perhaps a little unsightly, are easy to produce, simple to assemble, and reliable in use.

The piston rods are connected to walking beams, the ends of which are attached to the top of the boiler. The other ends are connected via shafts to the cranks on the geared jackshaft ahead of the front axle. This shaft is geared to the axle to power the engine. Since the other axle is unpowered, this engine could technically be called an 0-2-2T.

Interestingly, the locomotive, which was supplied in kit form, came with a period coach -- actually a stage coach on a railroad chassis. This coach was well below Aster's usual standard. It's body was made entirely of etched brass sheet and die-crunched plywood. The chassis is better, being all brass and incorporating an interesting suspension system. Despite it's faults, I'd like to have two or three more (any out there?).

The run

Run day was what I consider ideal steamup weather: temperature in the mid 40s, calm air, and bright sunshine. It's brisk but not oppressive. I prepared the engine in the usual way. The lubricator has no drain, so had to be sucked out with a syringe. This tiny engine seems to have more oiling points on it than much bigger locomotives. To fill the boiler I removed the plug on top and the plug on the side. I added water through the top until it drained out the side, then I replaced both plugs. The meths tank was filled until fuel came out the overflow.

Being internally fired, a suction fan is required to get it going. I stuck the fan on the stack, turned it on, and lit the fire. Alcohol immediately bubbled out, setting the track alight. No problem. Steam came up quickly, at which point I discovered that the check valve on the opposite side of the boiler was stuck open. Steam came boiling out the filler pipe. A couple of sharp taps with a wrench solved that problem.

Once steam was up to blow-off pressure, I removed the fan and moved the control lever to forward. . .too far. The engine was off like a rocket. Strangely, this engine is geared up, whereas most geared locos are geared down. This didn't help the speed problem much. After sprinting around half a lap I caught up with it and shut the valve. Meths immediately boiled over again, setting the local vegetation alight. No problem. I carefully tapped the lever open a bit and the engine set off at a nice, steady pace. It is possible to run this loco slowly, though it takes a certain knack.

Once running at a sane speed, all was well. The engine runs smoothly and quietly, with only the suggestion of exhaust steam at the stack. There were two or three stops for fuel, setting the landscape alight each time (no problem). It is theoretically possible to keep this engine in steam indefinitely, feeding water in through the check valve. However, with no water glass, it becomes a little problematic. Even without trying to refill it, I got a good 20 minutes out of the small boiler, which I thought quite good. This is a wonderfully quirky engine with great charm, and lots of fun to run.

|

|

|

| Builder | Aster (Japan) |

| Date built | 1994 |

| Gauge | 1 (45 mm) |

| Scale | 1:32 (nominal) |

| Boiler | Vertical, multi-flue |

| Fittings | Safety valve, filler plug, check valve |

| Fuel | Alcohol |

| Blow-off pressure | 45 psi (3 kg./ sq. cm.) |

| Cylinders | Two, double-acting piston-valve |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 2 pounds, 2 ounces |

| Dimensions | Length over end beams, 6"; width, 3-1/8"; height, 5-5/8" |

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.