Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

May 2007

Fred Freeman's Hunslet

by Marc Horovitz

The Hunslet Engine Company was founded in 1864 in England and exists today in Leeds. Amongst modelers, it is probably most famous for its small industrial tank engines, and especially so for those that worked the Welsh slate quarries. However, the company produced industrial engines in many gauges and exported them to 30 countries. Among their more unusual products were the 0-3-0 engines produced for the Listowell & Ballybunnion monorailway in Ireland. Although the name on this month's offering is, I believe, fictitious, the engine bears a strong resemblance to Lilla, one of the larger quarry Hunslets, now working on the Ffestiniog Railway in Wales.

The engine

Sadly, I know nothing of the builder. However, this is a most interesting model. It is equipped with a Smithies boiler, which is internally fired. The saddle tank is functional, carrying water with which the boiler is fed through a hand pump on the right running board. A plastic balance pipe connects the legs of the tank under the boiler. The backhead is fully equipped, with throttle, blower, pressure gauge, and a (nearly useless) whistle tucked up under the cab roof. Lamentably lacking is a water glass, so, when pumping up, you have to sort of go by feel. Little and often is the byword.

The engine is alcohol fired via a two-wick burner in the firebox. Two alcohol tanks reside in the cab, one on either side. A fuel-control valve is disguised as a brake screw, which releases the fuel to a sump under the footplate.

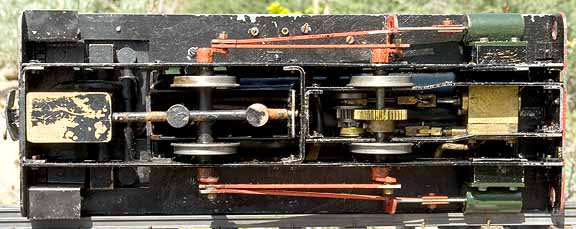

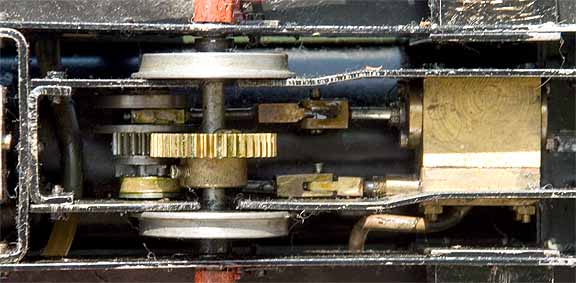

Perhaps the engine's most interesting feature is its drive. The visible cylinders on either side are dummies. The engine is, in fact, powered by a single, double acting, D-valve cylinder between the frames. This is geared 2:1 to the axle, not only providing the correct number of exhaust beats per revolution of the drivers, but also making the engine much more controllable. The cylinder and gears are supported by a second frame system contained within the engine's overall frame. Even though the engine is not highly detailed, the workmanship is to a high standard.

This engine has a tender that did not come with the engine. It was built after the fact by Frank Warren, the engine's owner at the time, as a sort of accessory car. The front half holds the suction fan required to get the engine started, while the rear holds odd bits, including the detachable pump handle. It is nicely painted to match the engine.

The run

Although I have had this engine for quite a long time, I had never run it. This was partly due to the fact that along with it came its reputation of setting the railway alight as it passed, by spilling flaming meths everywhere. So it was with some trepidation that I approached the beast.

The sun had come out after a few days of rain, and the temperature was probably in the upper 70s under blue skies. I prepared the engine in the usual way. When all was ready I set it on the track and dropped the fan into the stack, opened the fuel valve, and lit the wicks. It didn't take long before pressure came up and I could remove the fan and turn on the blower. And it didn't take long before the alcohol overflowed and lit up the surrounding area. I closed the fuel valve, which temporarily solved that problem.

In examining the engine and thinking about the fire problem, it occurred to me that this was not, in fact, a standard chicken-feed fuel system, but just a drip system. When the valve was opened, alcohol simply flowed into the sump. You had to close the valve to stop the flow -- it wasn't self regulating. With that thought in mind, I changed my tactic. As with pumping water into the boiler, I opened the fuel valve often, but just for a few seconds. This largely solved the fire problem.

With pressure up, I opened the throttle and gave the engine a push. After the lines had cleared of water, it moved smoothly off, though with a discernable knock. It was easily controllable and, due to its weight and the gearing, ran at a nice, sedate speed. Even with the throttle opened wider, it did not want to run away.

This is definitely a hands-on engine that takes some watching. The run went smoothly and could have gone on indefinitely. I am looking forward to getting in some more time with this loco and learning its tricks and ideosynchrasies (and determining where the knock is coming from). I believe it has been wrongly maligned and really just wanted a little understanding.

Addendum

On Februaty 26, 2009, I received the following from Harvey Watkins, the engine's original owner:

"This was one of the last Hunslets made by Fred, after he had retired from Bedford to live at Burnham on Sea, near his daughter. Fred was in poor health and only building a very few small engines at this time. I don't know if any more were produced at Burnham. I travelled down there to pick up two.

"The one you now have was in 'kit form:' cabless and unpainted. I painted, lined out, detailed, and reassembled the loco, and added the cab and rear sheet so that, as you have surmised, the loco was finished to resemble Lilla, a one-off large Hunslet from the Penrhyn Quarries. As constructed, Fred's loco was a little overscale to be a typical quarry Hunslet. The second plate on the cabside commemorates this work, Worcester Park being the area of North Surrey where we lived at the time.

As you say, Fred's drip feed system was rather unregulated, and we had lots of fun beating out flames in the lineside vegitation of our small yard but, with the system turned down so as to be almost closed, we had lots of fun.

"And the name. Well, Blodeuwedd is a princess-deity featured in the book of Welsh folktales and folklore, The Mabinogion. Conjured out of flowers by the welsh wizards, she is the goddess of flowers and of owls! Sweet one moment, scratch your eyes out, the next. Seemed appropriate!

"Well, like so many engines that have passed this way, she had to be sold to help finance the purchase, so went on her travels. She is fondly remembered."

|

|

|

| Builder | Fred Freeman (UK) -- (Finished and painted by Harvey Watlins) |

| Date built | 1976 |

| Gauge | 0 (32 mm) |

| Scale | 16mm |

| Boiler | Smithies |

| Fittings | Safety valve, throttle, pressure gauge, blower, whistle, check valve |

| Fuel | Alcohol |

| Blow-off pressure | 60 psi |

| Cylinders | One, double-acting D-valve, geared to axle 2:1 |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Weight | 6 pounds, 12 ounces (without tender) |

| Dimensions | Length without tender, 10-3/4"; width, 4"; height over stack, 5-5/8" |

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.