Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

November 2007

Archangel's coal-fired Jack

by Marc Horovitz

The prototype of this attractive locomotive was built by W.G. Bagnall in 1914 for the Cliffe Hill Mineral Railway in Leicestershire, which was begun in 1896 and closed in 1946. The railway served granite quarries in the area, some of which were reputed to have been in operation on and off since Roman times.

From the information I was able find, the line had two 0-4-2Ts, one built in 1911 (Mary) and one built in 1914 (Jack). Both were scrapped in 1957. Jack is a fairly typical industrial engine without much to distinguish it aside from pleasing proportions.

The model

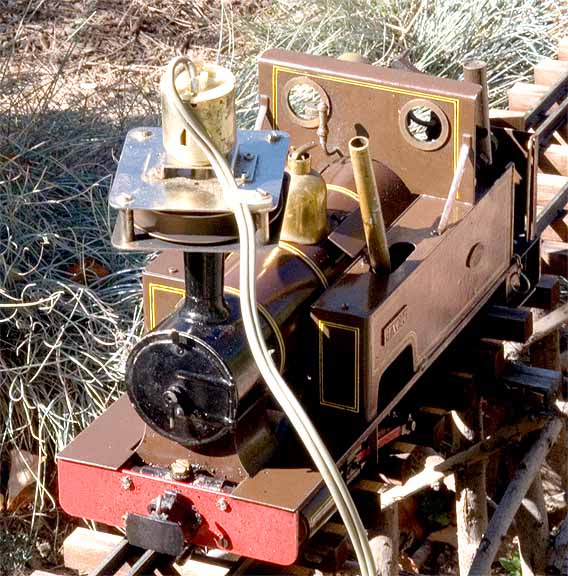

Archangel's model, too, has pleasing proportions. It has an open cab and working side tanks connected by a balance pipe, and with a hand pump in the left one. There is a second pump under the right-side tank that is actuated by a linkage to the crosshead. This functions the same as an axle pump, adding water to the boiler while the engine is in motion.

Frames are made of steel. The plain drivers are turned from solid steel bar, while the trailing wheels are brass.

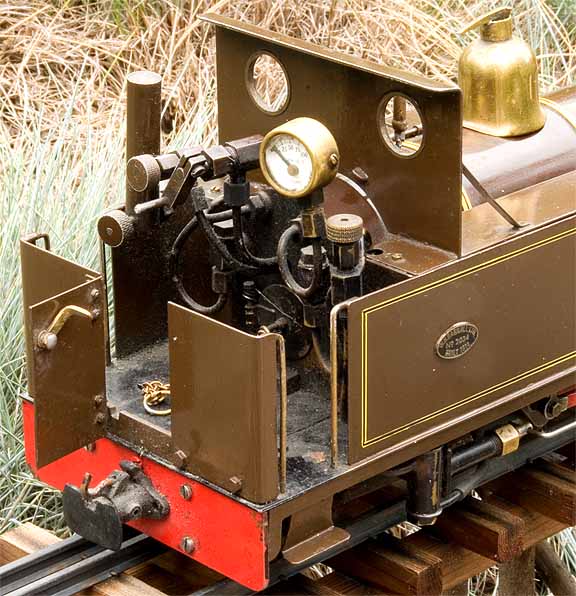

The open cab gives easy access to the controls. Fittings include a safety valve under the brass dome, a throttle, blower, whistle, and pressure gauge, plus bypass valve for the crosshead pump. The only thing lacking is a water glass.

The boiler is a locomotive-type, with five small flues and a larger superheater flue. There is no smokebox door per se, but the whole front pops off for cleaning and maintenance. The fire door can be opened by pulling a chain and, being spring loaded, closes by itself. An opening gate in the back sheet gives easy access to the fire door with a shovelful of coal. The ashpan can be dropped by removing a single screw. The grate is also held in place by a single screw.

Cylinders are outside the frames, while the valves are inside, unusually positioned a fair distance from the cylinders. The engine is reversed via slip eccentrics on the rear axle.

The run

The run day was warm but very windy, with the sun shining brightly. Since this is an internally fired engine, the wind isn't much of a problem.

To prepare the engine for its first firing (since I got it, anyway), I gave the smokebox and flues a perfunctory cleaning, oiled the engine all around, and added the necessary fluids. I then put it on the track and popped the fan into the stack. I filled the firebox with charcoal soaked in kerosene, turned on the fan, and lit the fire. To make a long story short, even after changing over to anthracite, I couldn't get the boiler pressure above 25 pounds, no matter what I did. Something was clearly wrong. Since the blower and blast pipes seemed to be properly aligned, all I could think of was dirty flues.

I dropped the fire and pulled off the smokebox front, ashpan, and grate. I cleaned the smokebox thoroughly, then cleaned all of the flues from both ends, through the smokebox and firebox, with the flue brush. I also cleaned the firebox and grate. This cleaning was followed by a spraydown with compressed air at around 100 psi.

With the engine thus cleaned, I reassembled it and rebuilt the fire, this time using charcoal soaked in meths, as I had been told that this will keep the engine cleaner (and I found this to be true). Pressure came up smartly. At 30 psi I removed the fan and turned on the engine's blower. A coal-fired engine likes a pretty fierce draft.

With the charcoal fire burning brightly, I started switching over to coal. The changeover was done fairly quickly and the engine was soon burning strictly anthracite, blowing off at 50 pounds.

I opened the throttle and gave the engine a push. The usual oily geyser ensued until the cylinders were warm, then the engine took off.

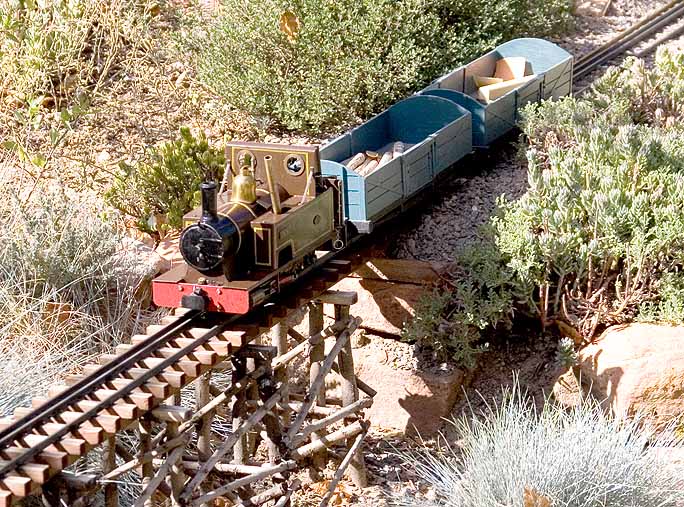

With the open cab, the controls are easy to get to. Controlling the engine was no problem at all. I gave it a train of two relatively heavy gondola cars and off it went. Every two or three laps I added a shovelful of coal to the fire.

The engine ran quite smoothly. When I closed the bypass valve to let the crosshead pump replenish the boiler water, the motion got a little jerky, as one piston stroke out of every four had to do a little extra work. However, this was not too bad and performance was not seriously affected. While a water glass would have been handy, once I got the feel of the engine, I really didn't miss it. The whistle was fairly useless, except perhaps as a blowdown valve.

Overall, the engine was a pleasure to run. While it took some attention, as would any coal-fired engine, it was relatively easy to keep pressure up and a good fire burning. With the pumps providing water as needed, the engine could have been kept in steam all day (or at least until the grate filled with ash) with no trouble.

|

|

|

| Builder | Archangel Models (UK) |

| Date built | 1984 |

| Gauge | 0 (32mm) |

| Scale | 16mm |

| Boiler | Locomotive type |

| Fittings | Safety valve, blower, whistle, pressure gauge, bypass valve, crosshead pump, hand pump |

| Fuel | Coal |

| Blow-off pressure | 50 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement (two) |

| Weight | 5 lbs., 0 oz. |

| Dimensions | Length over end beams, 10-1/4"; width, 3-7/8"; height, 5-3/8" |

Below the plate on the side of the cab you can see the crosshead pump, which is used to keep the boiler full while the engine is in operation.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2007

.