Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

March 2008

Aster's Climax

by Marc Horovitz

The Colorado & Northwestern Railway was organized in 1897 to take over the roadbed of the failed Greeley, Salt Lake & Pacific, which served the mountainous mining country west of Boulder, Colorado. The line limped along, through a variety of hard times and several incarnations and name changes, until 1919 when it was abandoned.

Aster's model is a replica of the railroad's locomotive No. 2, ordered from Climax in 1897. This engine was the only narrow gauge, three-truck (class C) Climax ever made, and it was also the first of its type ever produced.

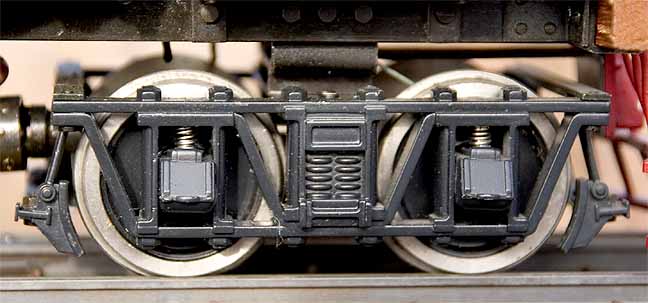

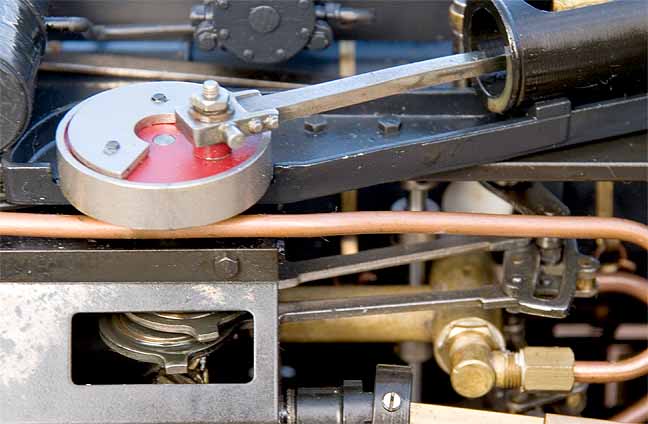

Climax locomotives are one of the three common geared locomotives in North America (the other two being Shays and Heislers). They are distinguished by having two inclined cylinders, one on either side of the boiler, that drive a transverse jackshaft. This jackshaft is geared to a longitudinal drive shaft, complete with universal joints, that, in turn, are geared to each axle via skewed bevel gears.

The model

I built this locomotive from a kit when it first came out in 1982. Like almost all of Aster's engines, this one is well designed and the kit went together smoothly.

Aster's model is a generally faithful reproduction of the prototype. It has two D-valve cylinders operated by full Stephenson's valve gear, controlled from the cab. It has a throttle, a pair of safeties, a pressure gauge, a water glass, and a bypass valve. There's an axle pump, driven off the jackshaft, and a hand pump in the second tender tank (the first tank is a dummy). Access to the cab is obtained via a removable cab roof.

The boiler is a single flue, gas-fired unit. Gas is stored in the second tender as well, the gas tank being situated in the water tank and being surrounded by water to keep its temperature up. As supplied, there's an unsightly gas line that passes from the rear tank to the burner. A displacement lubricator, disguised as an air tank, sits under the left-hand running board, ahead of the cab.

Due to its three-truck configuration, the engine has a total of six U-joints connected to square, telescoping drive shafts similar to those of the Shay.

The run

Today's run was short but sweet. I prepared the engine in the usual way, oiling all around, then adding fuel. I tried to pump water into the boiler with the hand pump, but here encountered problems. The pump was not functional. It had been a very long time since this engine had been run and the balls had seized in the check valves, as commonly occurs when an engine sits for long periods. So, instead of tearing it down to attend to the pump, I removed the steam dome and a safety valve and filled the boiler that way.

This gas-fired engine will not light at the stack -- the smokebox door must be opened, which is done by unscrewing the number plate. The fire lit right away the first time. Getting the smokebox door closed is sometimes difficult, as it heats up quickly. And relighting it after the fire goes out is definitely a job for gloved fingers. Anyway, the fire was not happy, as evidenced by the gurgling noise emanating from the stack. Adjusting it is tricky because the gas valve is very touchy. I had to relight the fire a couple of times, but it finally found its comfort level and all was well.

Steam came up promptly and the locomotive blew off right at 60 psi. I put it into gear and opened the throttle. The engine moved off with nary a sputter, as if it had run yesterday.

The run lasted perhaps 15 minutes, until the water level dropped below what I was comfortable with. This is a fine-running engine, smooth and sweet. One of the things I've always liked about Aster's Climax is that you can actually hear the whine of the gears as it runs. The throttle is a little touchy and the engine wants to run fast but ,once throttled down to a prototypical pace, it's a pleasure to watch.

|

|

|

| Builder | Aster Hobby Company (Japan) |

| Date built | 1982 |

| Gauge | 1 (45mm) |

| Scale | 1:24 |

| Boiler | Single flue |

| Fittings | Safety valve (2x), pressure gauge, water glass, throttle, check valve, hand pump |

| Fuel | Butane |

| Blow-off pressure | 60 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Stephenson's |

| Lubricator | Displacement |

| Weight | 12 pounds, 14 ounces |

| Dimensions | Length over all, 23 1/4": width, 4"; height, 6 3/4" |

The hand pump is accessed via the hatch cover. Unfortunately, it didn't work today.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2008

.