Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

June 2008

Finescale’s Peckett

by Marc Horovitz

Peckett & Sons Ltd. was a British manufacturer of industrial locomotives. Situated in the city of Bristol, the company began life in 1864 as Fox, Walker & Company. It acquired its later name in 1900, when it was taken over by Thomas Peckett. They produced their last steam locomotive in 1958 and finally ceased business altogether in 1962. The company produced engines of all sizes and gauges for industrial railways around the world. To garden railroaders, perhaps the company's best-known locomotive was Peckett's diminutive Cranmore-class 0-4-0ST, named for the Mendip Granite & Asphalt Company's Cranmore Quarries, where several were employed.

The model

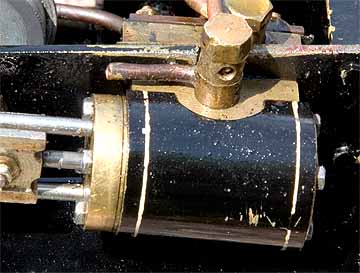

This model was produced by Finescale Engineering (Tony Sant). It is tiny and beautifully made. The boiler has a single-flue and is fired by a gas burner of the "poker" variety. The gas tank is carried under the roof of the cab and can be filled through the roof. Boiler fittings include a safety valve, throttle, pressure gauge, a surprisingly good whistle, and an ENOTS fitting with a check valve in the backhead. There's no water glass, so one must properly learn this engine to know when and how much to fill it when under steam. The smokebox door opens for lighting up. Inside the smokebox is a superheater coil to which is soldered a deflector that keeps the hot exhaust gases from directly impinging on the smokebox door and also helps to transfer some heat to the superheater.

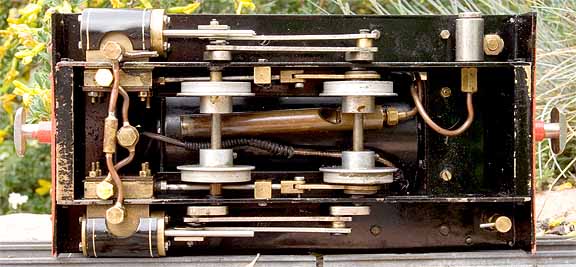

The outside, D-valve cylinders have inside valves, operated by slip eccentrics unusually located between the wheels and the frames. The valves themselves appear to be Teflon. They ride against port faces that are actually the inside surfaces of the frames. Steam connections to the cylinders are via banjo fittings. There are dummy drain cocks on the cylinders -- actually stubs off the exhaust lines that let out a little exhaust steam around the cylinders, as well as much of the exhausted steam oil, which helps to keep the engine clean. As originally supplied, the steam line was lagged with what appeared to be cotton string. On my example, much of this is gone.

The saddle tank is a dummy and conceals a boiler much larger in diameter than would be suggested by the smokebox, giving more water space and longer duration. The steam dome is a light press fit over the safety valve. It retains the tank in position -- once the dome is removed, the tank can be lifted right off.

A large displacement lubricator sits on the right side of the footplate. On the left is the gas-control valve, attractively disguised as a brake stand. As originally supplied, this locomotive had an exhaust regulator that was actuated by a rain cap over the stack. By the time I took possession, this had gone.

When I got the engine, it was in sad shape. It had evidently had a a long, hard life, and wouldn't go. I took it entirely to pieces. I tested the burner with the boiler off the chassis. It lit promptly and seemed fine. It was the chassis that was the trouble maker. I took the valves apart and found that one was deeply scored, as was its port face, to the point that it was not even remotely steam-tight. I smoothed the port face and the valve as much as possible. Performance improved marginally, but not significantly. With the port face (the frame) deeply scored, it seemed that a repair was impossible.

Then I hit on the idea of adding a piece of metal between the frame and the valve chest to form a new port face. I cut a piece of brass sheet to size and glued it in place with JB Weld. I dislike using glue on steam locomotives, but could think of no alternative, as the JB Weld would also serve to fill the gaps and scores. After it had set up, I redrilled the ports and polished the port face again.

Once the engine was reassembled, I put the air to it. Frustratingly, it seemed no better so, in desperation, I put it in a box, where it sat for years.

Then one day, with nothing better to do, I took the chassis out of the box and put the air to it again. Wonder of wonders -- it ran, and it ran strongly. Evidently, the valve had been stuck and had never seated properly against the new port face. What freed it I cannot say, but free it was. I put it all back together (except for the back sheet, which still needs a little work) and took it out to the track. Under steam, it ran splendidly.

The run

The test run for this month was done on a cool spring morning. After preparing the engine in the usual way, I lit the fire, which caught immediately. After a suitable amount of time I noticed an odd noise, with steam obviously leaking from the underside of the engine. I feared the worst until I realized that I'd left the whistle valve open from the last run. Once it was closed, all was well and pressure came up smartly.

With the gauge showing about 40 pounds, I pushed the engine forward to set the valves, then opened the throttle. After a little sputtering, it took right off, running smoothly. The locomotive, even without the exhaust throttle, was easily controllable, and it ran lap after lap at a prototypical speed. Later in the run I tied on a couple of large bogie wagons, which it handled with ease. After a wonderful run I shut the engine down and wiped it off. This is a well designed and beautifully crafted locomotive, as well as being a fine runner.

|

|

|

| Builder | Finescale Engineering Company (UK) |

| Date built | 1992 |

| Gauge | 32mm |

| Scale | 16mm |

| Boiler | Single flue |

| Fittings | Safety valve, pressure gauge, throttle, whistle, ENOTS filler with check valve |

| Fuel | Butane |

| Blow-off pressure | 45psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Slip eccentrics |

| Lubricator | Displacement |

| Weight | 3 pounds, 13 ounces |

| Dimensions | Length over end beams, 7-1/2"; width, 3-3/4"; height, 5-3/4" |

Below: With the roof hatch removed, the gas filler is accessible.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2008

.