Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

July 2008

Argyle’s 0-4-4T Forney

by Marc Horovitz

Matthias N. Forney developed the Forney locomotive in the early 1860s. It was essentially an industrial tank engine with a large water tank behind the cab. This tank was supported by a four-wheel truck. Forney locomotives almost always had four driven wheels in a rigid, non-articulated frame beneath the boiler. The most common wheel arrangement was 0-4-4, although some 2-4-4s were build for the Maine two-foot-gauge lines. Forneys were built in a wide variety of different gauges and were used extensively on early elevated municipal railways, as they were designed to run as easily in reverse as forward.

Maine was the US capitol for two-foot-gauge railroading, with six or seven different two-foot-gauge lines. The Sandy River & Rangeley Lakes was the biggest and best known. Of the two dozen locomotives the railroad owned or leased over its history, at least half were Forneys, most being 0-4-4s and the remainder being 2-4-4s. Sandy River No. 20 was built by Baldwin in 1903 and scrapped in 1935, having been retired for more than 10 years.

The model

This model of No. 20 was built by Argyle Locomotive Works (Gordon Watson) of Australia. It is a detailed and faithful replica of the original except in one important feature -- the gauge. Whereas the prototype was 2' gauge, the model is 3', running on 45mm track. It is one of a series of 38 similar models produced between 1992 and 1996.

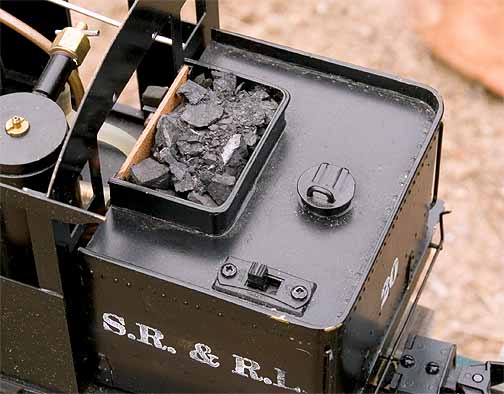

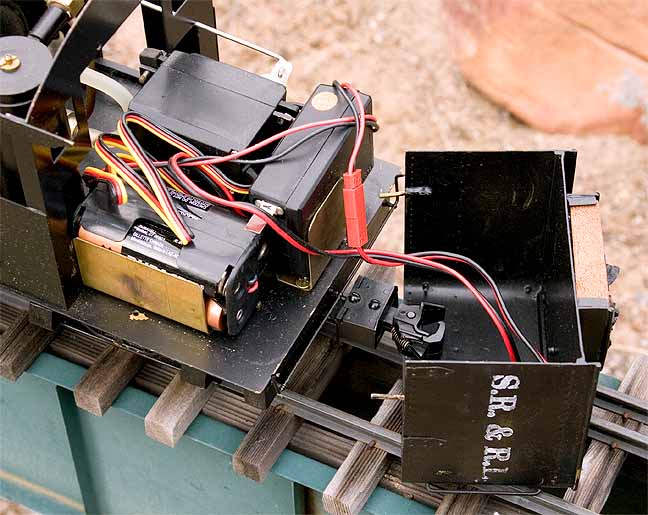

I acquired my example from a fellow I met at a train show. The locomotive was used and came with factory-installed R/C for both throttle and reversing gear. The cab roof lifts off, revealing a neat and orderly cab. A large butane tank sits at the rear of the cab on the left side. The engine is fitted with the radio-controlled throttle, a water glass, a pressure gauge, a safety valve in the steam dome, a Goodall-type filler valve under the lift-off sand dome, and a blowdown valve in the dummy firebox. The boiler is a typical, single-flue gas boiler with a poker burner.

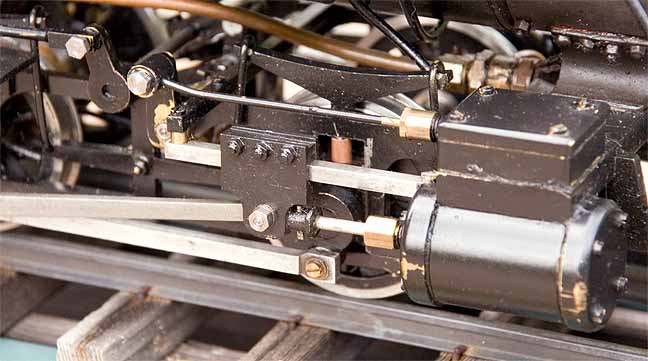

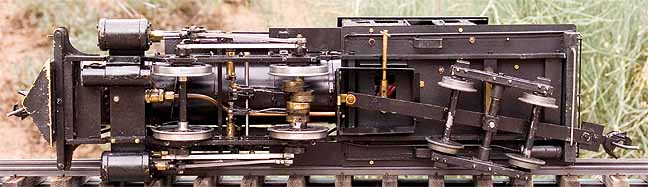

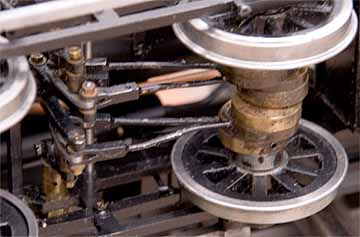

Full, working Stephenson's valve gear controls the two D-valves. A displacement lubricator sits under the smokebox, accessible from the left side. The chassis is fully sprung. The trailing truck is pivoted at the end of a radial arm to give it plenty of side play to get around some pretty sharp curves. Batteries and the radio gear are concealed in the lift-off bunker. Lettering on the cab and bunker was evidently done with rubber stamps.

This model has a suspension problem that had me flummoxed. It lists slightly to the left. Upon close examination, the right axlebox appeared to have a problem. It wouldn't travel its full distance. I removed the stays and dropped the front axle. Atop each axle box is a hole into which is set a spring. Projecting down from the frame, to engage the coil spring, is a small roll pin. I found the roll pin on the right was offset just enough to foul the spring when it was compressed.

I removed the roll pin and reassembled the axle. The problem was not solved. I took it apart again and found that the axle box still wouldn't travel the full distance. After some careful and judicious filing and scraping, I got it sliding smoothly the whole way. Problem still not solved. I tried extending the spring on the low side. Nope. Finally I gave up and just installed some small blocks that now ride between the frames and the axle boxes. Problem solved -- or at least the symptom has been solved. Perhaps it was nothing more than the engine being heavier on the left side, as that's where the batteries and fuel tank are.

The run

Run day was warm and sunny. I prepared the engine in the usual way, removing the safety to fill the boiler instead of using the Goodall valve. I had some difficulty in filling the gas tank, but eventually got enough in for a run. I lit the fire at the stack. It was a little finicky, but finally flashed back into the boiler, where it was stable.

The needle was off the pin in a few minutes. After about eight or nine minutes the safety let go at 45 pounds. I turned on the radio and receiver and opened the throttle. The engine moved for half a revolution of the drivers, then seized. I tried it in reverse, with the same result. The engine definitely wasn't going to self start. I put it in forward gear and pushed. It was very lumpy, as steam condensed into water in the cylinders. Finally, the engine loosened up and consented to run under its own power. After a lap or so, operation became very smooth.

Once everything was good, operation became a pleasure. Response to the radio was not instantaneous, but lagged by a few seconds. Also response was not abrupt, as it is with many engines. To start from standing, I opened the throttle fully. The engine started moving slowly, at which time I closed the throttle most of the way. The result was a slow, smooth, prototypical start, this running light. Stopping was accomplished by closing the throttle in advance of the intended stop. The loco would coast to a realistic stop. With a little practice, I could get it to stop where desired. This was fun.

The run lasted only about 20 minutes. This was, I suspect, because I hadn't been able to fill the fuel tank completely. However, the engine was a pleasure to run. With the Goodall valve to replenish the boiler, it could be kept in steam indefinitely, wih brief stops for refuelling.

|

|

|

| Builder | Argyle Locomotive Works (Australia) |

| Date built | circa 1994 |

| Gauge | 45 |

| Scale | 15mm |

| Boiler | Single flue |

| Fittings | Throttle, safety valve, pressure gauge, water glass, Goodall filler valve |

| Fuel | Butane |

| Blow-off pressure | 45 psi |

| Cylinders | Two, double-acting D-valve |

| Reversing gear | Stephenson's |

| Lubricator | Displacement |

| Weight | 9 pounds, 2 ounces |

| Dimensions | Length over end beams, 14-7/8"; width, 4-3/16"; height, 6-5/8" |

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2008

.