Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

October 2009

LBSC 2-1/2"-gauge 0-4-4T

by Marc Horovitz

LBSC, the legendary British model-locomotive designer and builder, loosely patterned this locomotive after a Southern Railways 0-4-4T commuter locomotive. Like many of his models, it was not intended to be a dead-nuts scale model.

The model

Having built ten or so live-steam locomotives in my life, I'd never made one from someone else's plans. I thought it might be a good idea to build someone else's design, primarily as a learning experience. I felt that by taking on someone else's design, I might gain some insights into the way that person thinks about engines.

I began casting about for a suitable project, eventually settling on this design by LBSC, originally published in the magazine English Mechanics in 1934. I picked this engine for several reasons. One was that it was relatively simple, with a single, large cylinder and a Smithies boiler. Another was that I already had an example of this locomotive (read about it here), which I figured might be a useful reference if I ran into a snag.

I then started looking about for a set of drawings. I was fortunate in finding John Baguley, a British modeler with a very interesting web site. John had redrawn this particular engine from the original plans, in digital form, and was thus able to e-mail them to me.

After printing them out full size, and tiling them together, one look at the four large sheets told me I was in for a different sort of engine-building experience. For one thing, all of the dimensions were fractional, not decimal, to which I was accustomed. Also, I soon discovered that not all of the information was there. It was assumed that you already knew how to do some things, which were implicit in the drawings. Along with the drawings came scans of the original 1934 articles, which were actually not that helpful.

The next thing was to locate wheel castings. It is traditional to buy rough, cast-iron wheel blanks, then machine them yourself. Again, I was fortunate in finding them commercially available, this time through the Gauge 3 Society of Britain.

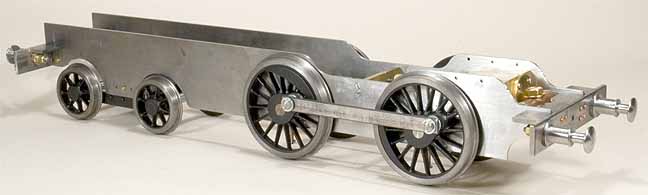

Construction commenced with the heart of the engine, the cylinder-and-valve assembly. The design was straightforward and easily understandable. A set of castings had been produced at one time for this engine, but I did not have them. This meant that I had to produce everything myself (except the wheels) from the solid.

Construction was relatively straightforward, once I got used to this decidedly different approach. The only real setback in the whole project came in the early days. While drilling the exhaust port, I accidentally drilled through to the bore of the cylinder, which was already finished. I remedied the situation by silver-soldering a piece into the hole, then reboring the cylinder.

While the original EM articles offered little aid, I found LBSC's book on building the Tich to be a valuable resource, especially so when it came to turning the rough, cast-iron wheels, something I'd never done before. However, under the master's tuteledge, all went well.

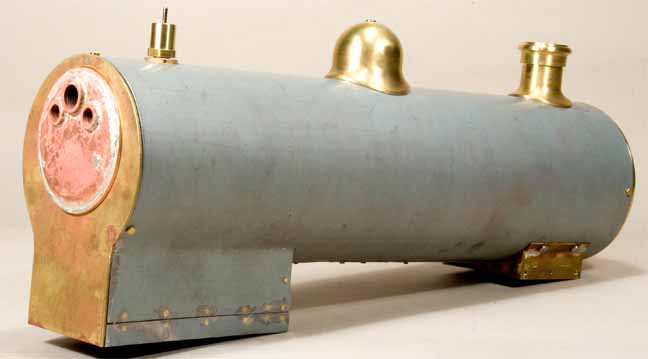

Once the chassis was complete and running smoothly on compressed air, it was on to the Smithies boiler. I made the inner barrel out of copper pipe, while the outer wrapper I rolled up out of sheet steel.

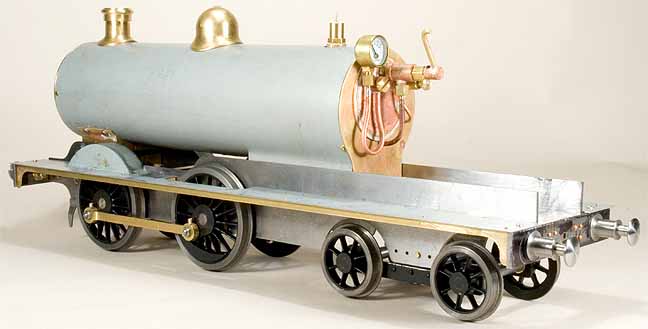

Once the boiler was finished, I mounted it on the chassis and gave the whole its first steam test up on blocks. It lived! Performance was strong and smooth the first time out -- most gratifying.

Next came the sheet-metal work (cab, tanks, bunker, footplates) and details. I was surprised at how long even this relatively simple engine was taking but I was learning a great deal along the way.

One glorious day I pronounced the engine finished. But then I was faced with the agony of painting the monster. This was finally accomplished, not to the high standard to which I had aspired but to a minimally acceptable one. Paint has always been my nemesis.

But, it was finished and it runs. My goal of procuring an education through building a published design was fully accomplished, and a great education it was.

The run

Since I have no gage-3 track at my disposal, the run was necessarily up on blocks. This was the first run since the engine had been painted and reassembled, so I was a little nervous. I prepared it in the usual way, put a fan in the stack and lit the fire. Before long, the pressure was up to 20 psi and I removed the fan and turned on the blower. The blower knob is a little small -- I need to replace it with a larger wheel.

Pressure was soon up to blow-off. I opened the throttle and nothing happened. The wheels were quite stiff when I tried to rotate them, probably from being new and sitting around for a while. All of a sudden it took off, running smoothly. I turned off the blower and played with the throttle, watching the engine run at different speeds. All was well, with the loco running strongly with an audible exhaust beat and some mechanical noise. I would expect some of the mechanical noise to go away when the engine is sitting properly on the rails and its moving parts aren't flapping around in mid air.

After a good run I blew out the fire and allowed the engine to coast to a stop. I opened the blower to release any residual pressure and to prevent a vacuum from forming in the boiler when it cooled. This was a good first run but I'm really looking forward to seeing it go on the track.

While there is no nearby gauge-3 track at present, there should be one soon. Mike Bigger and I took a trip last summer to Jim Hadden's, in Utah, to pick up a surplus gauge-3 loop that he had. This a historic track, having been built in the 1930s by George Thomas. Jim had acquired it from George's son Bob but never used it. It is heavily built and in remarkably good shape. We brought it back to Colorado, where it will be erected in Mike's backyard. Watch this space.

Here's a movie of the engine in action. If it doesn't work, click here to go to YouTube.

|

|

|

| Builder | Marc Horovitz |

| Date built | 2009 |

| Gauge | 2.5" |

| Scale | 1:24 |

| Boiler | Smithies |

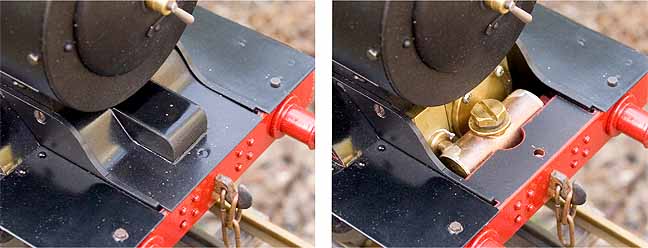

| Fittings | Safety valve, throttle, pressure gauge, blower |

| Fuel | Alcohol |

| Blow-off pressure | 60 psi |

| Cylinders | One, double acting, D-valve |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Weight | 11 pounds, 2 ounces |

| Dimensions | Length, 17-1/4"; width, 4-1/2"; height, 7" |

Below: A crude builder's plate is riveted to the engine, out of sight.

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2009

.