Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

May 2005

LBSC’s 2-1/2" gauge 0-4-4T

by Marc Horovitz

The prototype, in this instance, is of little importance. It was just an excuse to build an engine, really. The model is patterned after a Southern Railways "Brighton" 0-4-4T but, as is often the case with LBSC's locomotives, liberties were taken -- this time for the sake of simplicity.

The model

This locomotive was designed by Lillian Lawrence, better known as LBSC or Curly. (We have published another of LBSC's engines, Small Bass, where you can find a brief synopsis of his remarkable life.) As with most of LBSC's engines, it was serialized in a magazine as a construction series: this one in English Mechanics in June and July, 1936.

The engine came about as a result of readers requesting a largeish-but-simple locomotive following the publication of an 0-6-0 in 0 gauge, then a similar one in 2-1/2" gauge, both of which proved quite popular. This engine, like the 0-6-0, has a Smithies boiler, the usual backhead fittings (but no water glass), and a pump that could be used to pump water into the boiler from an external source (the water tanks are dummies). The boiler is fired by a huge, four-wick alcohol burner, fed by a monstrous (to someone mostly used to smaller, gauge 1 and 0 engines) tank under the footplate.

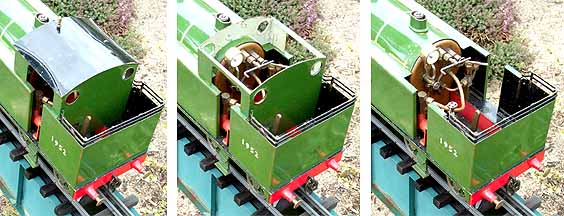

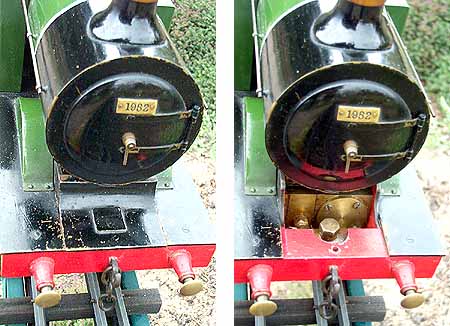

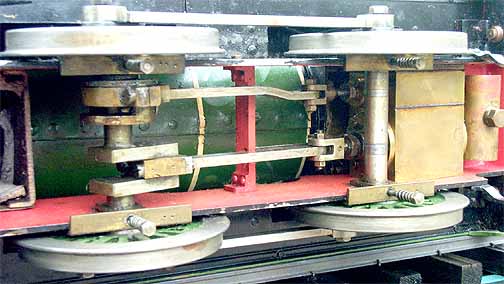

There is a single, large cylinder between the frames, with a slip eccentric controlling a D-valve. The drivers are sprung (although LBSC said that you could just run the axles through holes in the frames, if you wished). A displacement lubricator lives under a removable plate just below the smokebox and there is a whistle concealed under the right-hand side tank. The cab roof is removable, and so, surprisingly, is the whole cab, making everything inside very accessible. Castings were made available at the time, although they weren't necessary for the cylinder.

The model in question was made by an unknown builder. Whoever built the engine did a workmanlike job and the paint finish (chipping in several places) is all that could be wished for in a working locomotive. LBSC's engines were designed for use, not show. It was his goal to put the skills for the making of steam locomotives into the hands of anyone who desired them. He succeeded admirably.

The name on the side of the engine is Doris. Since this is not the name LBSC gave to the design, one must speculate as to its origins. The builder's daughter? (Possibly.) Wife? (Most likely.) Mistress? (Come, now!) Also, the loco's number is shrouded in mystery. I speculate that it is the year in which it was built. This is certainly within the realm of possibility -- less than 20 years after the design appeared in print.

The run

Sadly, I have no 2-1/2"-gauge track on which to run the engine (yes, the pictures of it were faked up). so I decided to run it on blocks. On the first try, with compressed air, it didn't run at all. The air just went straight up the stack. It was obvious that the valve was not seating. I laid the engine on its side and gave the steam chest a little whack. Then I put the air to it again, with it still on its side. Since it has but one cylinder, it is not a self starter. I gave the drivers a flick, with the throttle open, and the wheels began to rotate. I closed the throttle, set the engine back up on the blocks, and tried it again. All was good. It ran well in both directions and could be throttled down to a surprisingly slow pace. There's a lot of energy stored in those spinning drivers. The whistle gave a mournful, half-hearted hoot when the lever was pressed.

This locomotive has seen quite a bit of use. I'd like to think that it gave its anonymous builder (and his wife) much pleasure over the years. It runs with a definite clank -- evidence of wear. It would probably be quieter on the track.

I decided to give it a run on steam. By rights, I should have given it a proper boiler test, but I didn't, which was naughty of me. I had it running on 40 psi of compressed air without trouble, so I went ahead with the steam test. With the locomotive propped up on blocks, I filled the lubricator, the boiler, and the massive alcohol tank. This is the biggest, alcohol-fired engine I've ever run. It has a real presence. Whenever I fire up an old engine I get a sense of bringing history to life. It's exciting.

I set my Aster fan in the smokestack, turned it on, and lit the four big wicks. The engine began to get hot. After a few minutes, it was evident that there would be trouble. The soldered-together whistle valve seemed to be coming apart and it leaked steam copiously. There was also an old, soft-soldered repair to the pressure-gauge supply tube that didn't hold, letting out more steam. In fact, the cab was filled with steam.

I decided to keep going though, and the needle eventually left the peg. When 20 pounds showed on the clock, I removed the fan and turned on the engine's blower. Pressure steadily rose to 40 psi (it never did reach blow-off pressure, whatever that may be), at which time I opened the throttle. I gave the wheels a few turns manually (the mechanism is very loose) and it began to catch. It reversed itself several times until, with a last flick, the wheels started turning steadily.

Pressure was down to under 20 pounds by this time, and I couldn't get it to come back up. Too much was being lost. However, the engine ran for a good long time on almost nothing. It ran well in both directions, although there was a great deal of mechanical noise. It could probably use a good going through. The run, despite its problems, was extremely satisfying. The engine was perfectly controllable and, on the track, would no doubt have been able to haul a reasonable train. Fixing the leaks will not be a huge job and I would expect the performance to be markedly better afterwards.

There was one last, charming surprise to this endearing locomotive. When examining it for the first time, I discovered that its builder had glued a Saint Christopher's medal under the footplate, no doubt to safeguard the engine in its travels.

.

|

|

|

| Builder | Unknown (design by LBSC) |

| Date built | 1952? |

| Gauge | 2-1/2" |

| Scale | 1/2" = 1'-0" |

| Boiler | Smithies |

| Fittings | Safety valve, throttle, blower, pressure gauge, blowdown, whistle |

| Fuel | Alcohol |

| Blow-off pressure | 60 psi? |

| Cylinders | One, double acting, D-valve |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Weight | 14 lbs. |

| Dimensions | Length over end beams, 17-1/4"; width, 4-5/8"; height, 7" |

This nicely proportioned locomotive was made to be a workhorse, not a display piece. While it is patterned after a specific prototype, it really can't be considered a scale model. It is heavily built by today's standards.

.

.

To the right of the blower, on its own stand, is the leaky whistle valve. On the left of the footplate is the hand pump, for taking water from an outside source. The alcohol tank can be seen between the frames.

.

.

The view beneath. The crank axle is clearly visible, powered by the single cylinder. The whistle (which doesn't work very well) is under the footplate behind the drivers. You can see the four-wick alcohol burner, with its twin feed pipes. In the lower right corner is the Saint Christopher's medal.

.

.

Right: With the temperature in the low 30s, and despite the steam leaks in the cab, the engine ran well, if a little noisily. It makes me want to build a 2-1/2"-gauge track.

.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2005

.