Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

January 2010

Mac Muckley's de Winton

by Marc Horovitz

The history of de Winton locomotives is discussed here. These tiny locomotives were used primarily in the slate quarries of Wales.

The model

This locomotive was scratchbuilt by Mac Muckley of Britain. I don't know when it was built but I believe it was in the mid-to-late 1990s. I acquired it in 2001.

It's a beautifully made engine, with a vertical, single-flue boiler lagged in wood. The boiler has cross tubes in the flue, low, near the fire. Fittings on this tiny boiler include just about everything: a throttle, pressure gauge, water glass, Goodall filler valve; blower, and safety valve. The steam line runs from the throttle to a displacement lubricator (with a drain!), thence to the cylinders.

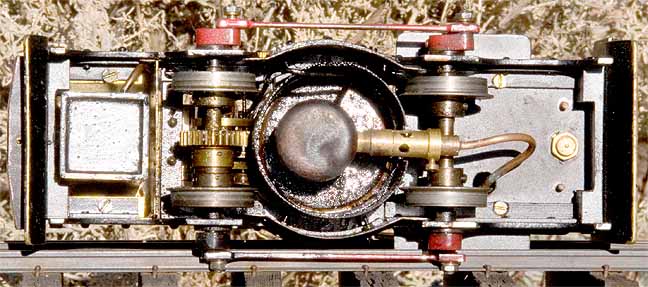

The steam motor is a pair of double-acting oscillators. The steam motor is geared to one axle in what appears to be around a 3:1 ratio. The other axle is powered by the side rods. A rotary reversing valve, controlled by a nicely made reversing lever, is built into the cylinders' port block.

This locomotive is gas fired. The storage tank is at one end and the gas-control valve is at the other. The burner amounts to a tiny poker-type unit built into a pan (a copper plumbing fitting) below the boiler. This engine is unusual among gas-fired locomotives in that it requires a draft to get steam up. The fire must be started with a suction fan, after which the blower takes over to keep it going.

The run

I oiled the engine all around, drained the lubricator, and fed the engine its various fluids. Before lighting the fire, I popped a fan into the stack and turned it on. I then turned on the gas and struck a match. As soon as I did this, trouble lurked. The fire would not stay lit. After multiple attempts I disassembled the burner and blew out its components with compressed air to clear any blockage, imagined or real.

With the parts back together again I gave it another go. Things seemed a little better this time. The engine raised enough pressure for one lap before the fire was gone again. After many more attempts, trying different things all the while, I finally had to call it a day -- hence, no video this time.

I'm wondering if Denver's altitude might have something to do with the problem. I know that it has affected other engines. Perhaps a different type of burner would be better. This engine will have to go into the backshop, where it will find plenty of company.

|

|

|

| Builder | Mac Muckley (UK) |

| Date built | Unknown -- mid 1990s? |

| Gauge | 0 gauge |

| Scale | 16mm |

| Boiler | Vertical, single flue with cross tubes |

| Fittings | Safety valve, pressure gauge, throttle, water glass, blower, Goodall valve |

| Fuel | Butane |

| Blow-off pressure | 45 psi |

| Cylinders | Two, double-acting oscillators |

| Reversing gear | Rotary valve |

| Lubricator | Displacement |

| Weight | 3 pounds, 0 ounces |

| Dimensions | Length over end beams, 7-1/2"; width, 2-5/8"; height, 6-1/8" |

Right: The gas filler valve is concealed by a pop-off brass cap on top of the tank at the other end.

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2010

.