Back to Loco of the Month homepage

Back to Sidestreet Bannerworks

.

April 2006

Berkeley Locomotive Works Cricket

by Marc Horovitz

The model

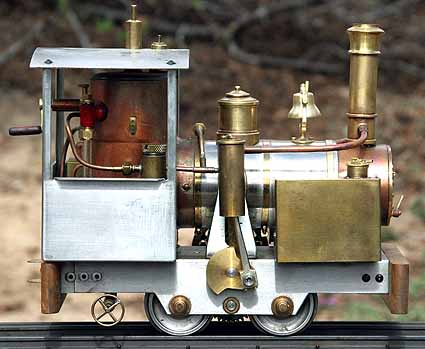

I acquired this locomotive from my friend, Rich Chiodo, for whom the engine was made by Berkeley Loco Works. Mr. O'Rourke was in the habit of customizing his engines according to the customers' wishes, and so it was in this case. This is the only two-cylinder Cricket ever produced.

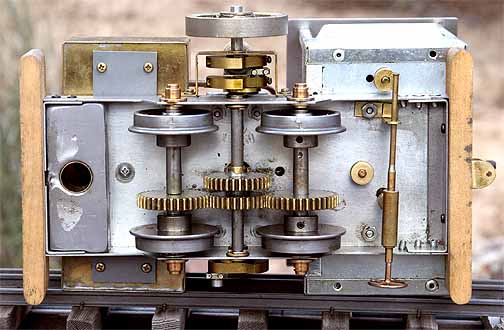

The engine has a pair of single-acting cylinders set 180 degrees apart. Because they are single acting, the engine still requires a flip of the flywheel to get it going. Cylinders are controlled by Teflon piston valves. The engine is reversed via slip eccentrics mounted between the counterweight and the frame on either side. Because of the cylinder on the flywheel side, there is a sort of auxiliary frame to help support the axle that the flywheel is on.

The engine is fired by butane gas. The boiler is a T-boiler, the "T" being a standard bit of plumbing. This engine is fitted with every conceivable fitting, including a safety valve, pressure gauge, water glass, blowdown valve, Goodall valve (under the ornate, lift-off dome), and a Mamod whistle without its lever. It has a bell, dummy wing tanks with cast-brass fillers, and wooden end beams.

When I acquired the engine, it was missing its bell, smokebox front, and exhaust lines from the cylinders to the stack. Berkeley provided me with a new bell and I made new exhaust lines from copper tubing. I also made a new smokebox front that is quite unlike the standard Cricket smokebox.

The run

Preparing the engine is much like other small locomotives. I drained and filled the lubricator and filled the boiler with distilled water. Filling the gas tank was problematic. A special, long adapter, supplied with the engine, is required to reach the tank. This didn't come to me, so I had to resort to removing the roof for access to the tank. Filling it was no problem.

I cracked the fuel valve until I could hear the gas hissing in the flue. I lit the fire at the stack and it flashed back at once, burning steadily in the flue. It was a warm day and pressure came up in just a few minutes. I opened the throttle and gave the flywheel a few spins. The engine showed signs of life right away, and was soon on its way.

I found it easy to control. Since it is a geared locomotive, with a double reduction, it ran slowly and sedately. It took no notice of irregularities in the track, or even the three heavy LGB cars I tied on behind it. It just kept on going. Reversing, however, was problematic. In theory, one should have only to rotate the flywheel in the opposite direction to reset the eccentrics. In practice, though, one of them wouldn't go, resulting in one cylinder that wanted to go forward and one that wanted to go back. Needless to say, neither won. On this day, I never did get the engine to go in the opposite direction.

That said, the rest of the run was delightful. This engine had the winning combination of good design and good craftsmanship. It lit instantly, raised steam quickly, and ran sweetly for a very long time.

|

|

|

| Builder | Berkeley Locomotive Works (Michael O'Rourke) |

| Date built | 1999 |

| Gauge | 1 (45mm) |

| Scale | 1:20.3 (15mm) |

| Boiler | Single flue, internally fired |

| Fittings | Safety valve, throttle, water glass, pressure gauge, whistle, blowdown valve, Goodall valve |

| Fuel | Butane |

| Blow-off pressure | 35 psi |

| Cylinders | Two, single-acting piston valve |

| Reversing gear | Slip eccentric |

| Lubricator | Displacement |

| Weight | 4 lb. 12 oz. |

| Dimensions | Length, 7"; width (over flywheel), 4-5/8"; height, 6-1/8" |

With the exception of the flywheel, this engine looks much the same from either side. All other Crickets had only one cylinder. Early ones had oscillators. The wing tanks are dummies.

.

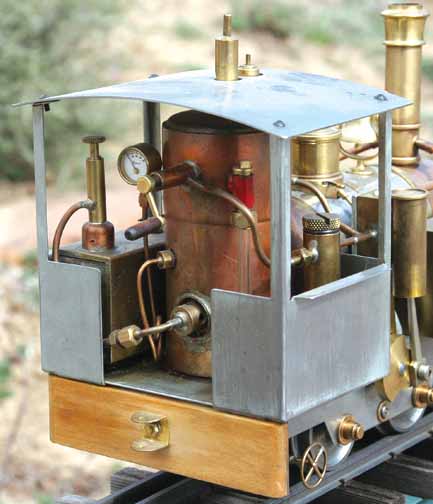

Below: The burner resides in the flue that penetrates the "T" part of the boiler.

.

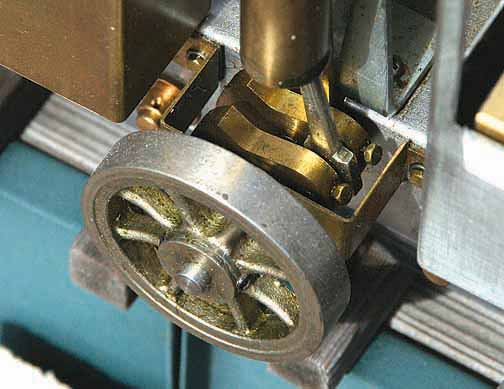

Above: The blowdown is controlled by this attractive wheel under the footplate.

Right: Because of the second cylinder, there is an auxiliary frame (the brass strap) to help support the flywheel's axle.

.

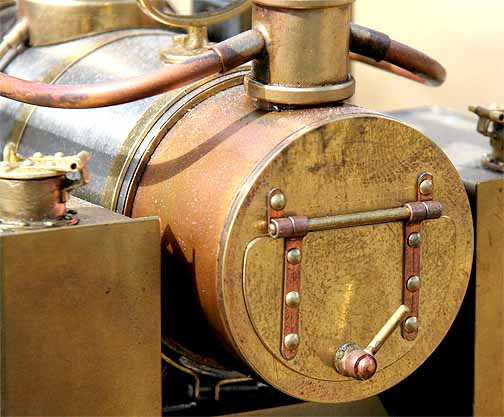

The new smokebox front is reminiscent of early industrial engines and is unlike the original Cricket smokebox front, which was lost. The new exhaust lines to the stack can be seen here as well.

.

The underside clearly shows most of the gearing. The center axle is actually a jackshaft, powered by a pinion above it. Note the lead weight (left) to counterbalance the T-boiler.

Back to Loco of the Month home page

Back to Sidestreet Bannerworks home page

This page and its contents

Copyright Sidestreet Bannerworks, 2006

.